Carbon fiber reinforced ceramic matrix composite material and preparation method thereof

A technology of ceramic matrix and composite materials, which is applied in the field of carbon fiber reinforced ceramic matrix composite materials and its preparation, can solve the problems of reducing the mechanical properties of composite materials, achieve strong designability, avoid catastrophic failure, and extend the expansion path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of carbon fiber reinforced ceramic matrix composite material comprises the following steps:

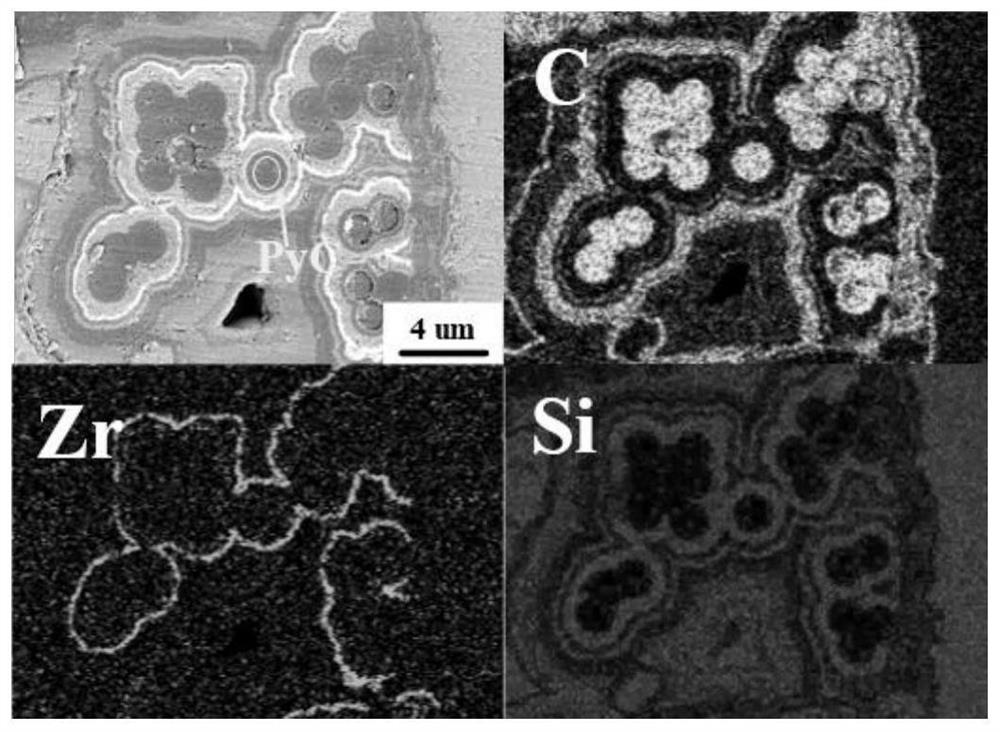

[0035] (1) Two perforated plates are used to press and shape the carbon fiber cloth to obtain a size of 40×4×60mm 3 The 2.5d prefabs were cleaned by ultrasonic cleaning, carbonized at 400°C under the protection of argon, ultrasonically cleaned with anhydrous ethanol, and then removed in a muffle furnace at 100°C for 8 hours. Curing glue. The preform was suspended in a vertical chemical vapor deposition furnace with a carbon rope, and the temperature of the chemical vapor deposition furnace was raised to 1100 °C at a heating rate of 7 °C / min under the protection of an Ar gas flow rate of 300 mL / min. Using CH 4 -Ar system deposits pyrolytic carbon (PyC) interface phase, chemical vapor deposition (CVI) process conditions of PyC interface phase: deposition temperature 1000 ° C, deposition pressure maintained at atmospheric pressure, CH 4 The gas flow rates of (99...

Embodiment 2

[0043] The preparation of carbon fiber reinforced ceramic matrix composite material, the steps are as follows:

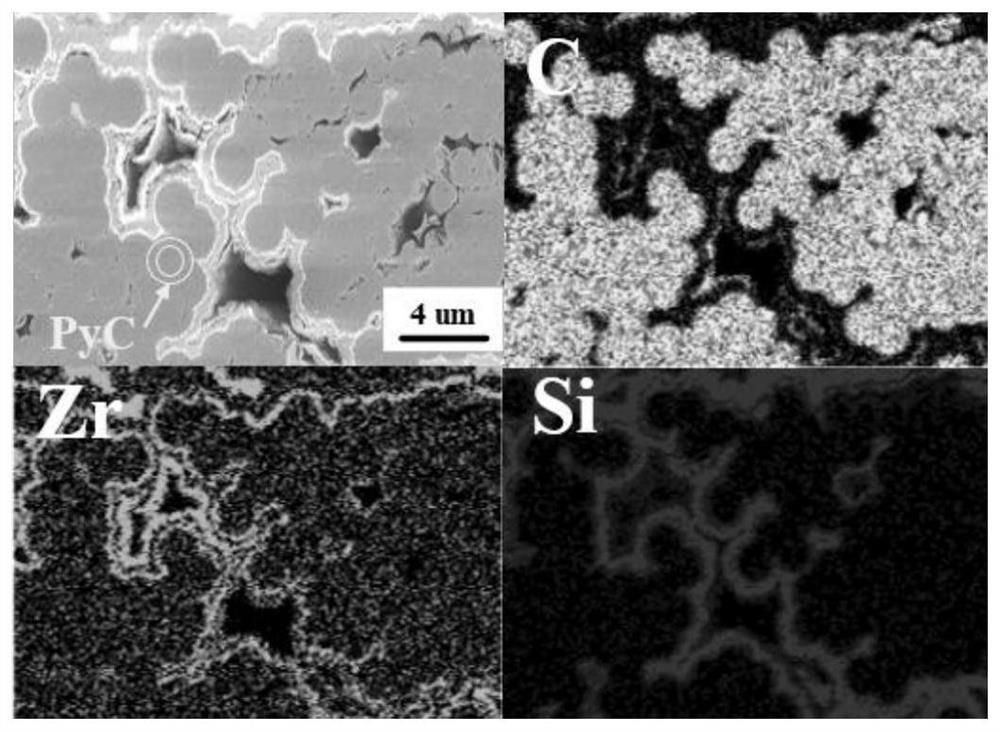

[0044] (1) Two perforated plates are used to press and shape the carbon fiber cloth to obtain a size of 40×4×60mm 3 The 2.5d prefabs were cleaned by ultrasonic cleaning, carbonized at 300°C under the protection of argon, ultrasonically cleaned with anhydrous ethanol, and then removed in a muffle furnace at 80°C for 10 hours to remove the fiber surface curing glue. The preform was suspended in a vertical chemical vapor deposition furnace with a carbon rope, and the temperature of the chemical vapor deposition furnace was raised to 900 °C at a heating rate of 6 °C / min under the protection of an Ar gas flow rate of 200 mL / min. Using CH 4 -Ar system deposits PyC interface phase, chemical vapor deposition (CVI) process conditions of PyC interface phase: deposition temperature 900 ° C, under normal pressure, CH 4 The gas flow rates of (99.99%) and Ar (99.99%) were 100m...

Embodiment 3

[0049] The preparation of carbon fiber reinforced ceramic matrix composite material comprises the following steps:

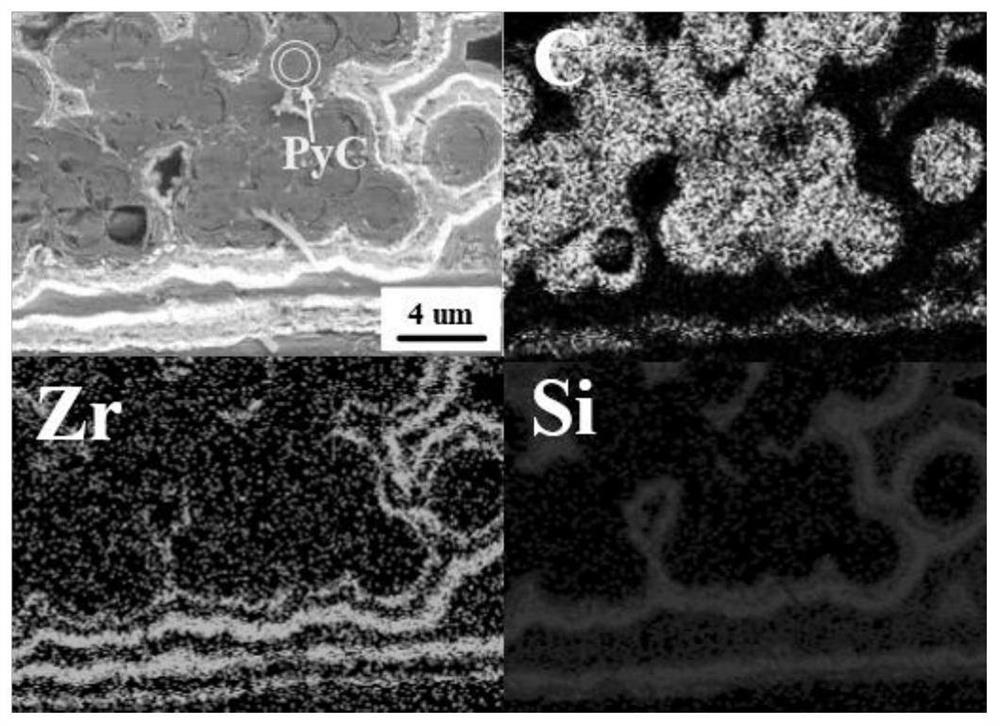

[0050] (1) Two perforated plates are used to press and shape the carbon fiber cloth to obtain a size of 40×4×60mm 3 The 2.5d prefabs were cleaned by ultrasonic cleaning, carbonized at 500°C under the protection of argon, ultrasonically cleaned with anhydrous ethanol, and then removed in a muffle furnace at 120°C for 5 hours to remove the Curing glue. The preform was suspended in a vertical chemical vapor deposition furnace with a carbon rope, and the temperature of the chemical vapor deposition furnace was raised to 1000 °C at a heating rate of 10 °C / min under the protection of an Ar gas flow rate of 400 mL / min. Using CH 4 -Ar system deposits pyrolytic carbon (PyC) interface phase, chemical vapor deposition (CVI) process conditions of PyC interface phase: deposition temperature 1100 ° C, under normal pressure, CH 4 The gas flow rates of (99.99%) and Ar (99.99...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com