Corrosion inhibitor for resisting carbon dioxide corrosion, preparation method and application thereof

A carbon dioxide and corrosion inhibitor technology, applied in chemical instruments and methods, earthwork drilling, drilling composition and other directions, can solve the problems of unstable corrosion inhibition performance, affecting the normal exploitation of oil and gas, formation damage, etc., and achieve corrosion inhibition. Good effect, the effect of expanding oil and gas production and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

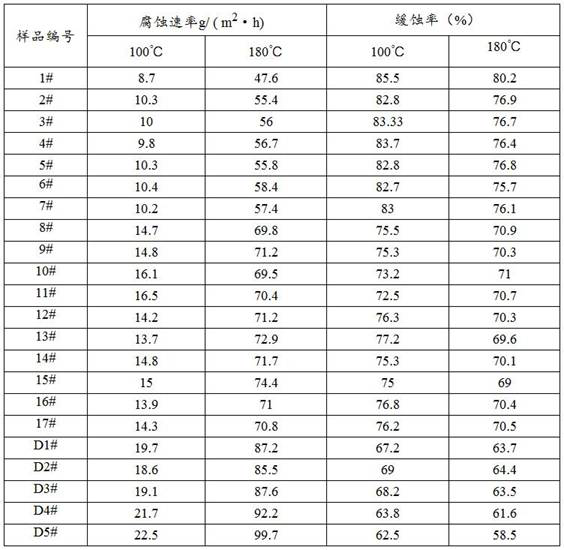

Examples

Embodiment 1

[0062] (1) Weigh 400.0g N-vinylpyrrolidone, 2.5g allyl polyoxyethylene methyl ether, 10.0g allyl polyoxyethylene epoxy ether, 87.5g bisallyl polyether (molecular weight average molecular weight 6000) was dissolved in 495.0g of absolute ethanol, nitrogen gas was introduced, then the temperature was raised to 65°C, 5.0g of azobisisobutyronitrile was added, stirred evenly, and reacted for 3 hours to obtain the first intermediate;

[0063] (2) Dissolve 100.0g of the first intermediate, 250.0g of N,N-methylenebisacrylamide, 100.0g of acrylamide and 50.0g of formaldehyde into 495.0g of absolute ethanol, add 5.0g of zinc fluoroborate, Adjust the pH to 2-3, then raise the temperature to 85°C, stir evenly and react for 6 hours to obtain the second intermediate;

[0064] (3) Weigh 500.0g of the second intermediate, raise the temperature to 85°C, add 70.0g of acetylenic alcohol and stir to react for 3 hours; then cool down to 40°C, add 30.0g of antimony trichloride, and stir for 0.5h to ...

Embodiment 2

[0066] (1) Weigh 150.0g N-vinylpyrrolidone, 5.0g allyl polyoxyethylene methyl ether, 10.0g allyl polyoxyethylene epoxy ether, 135.0g bisallyl polyether (average molecular weight is 10000) was dissolved in 698.0g of absolute ethanol, nitrogen gas was introduced, and then the temperature was raised to 75°C, 2.0g of azobisisobutyronitrile was added, stirred evenly, and reacted for 1 hour to obtain the first intermediate;

[0067] Steps (2) (3) are the same as in Example 1 to prepare corrosion inhibitor 2#.

Embodiment 3

[0069] (1) Weigh 545.5g N-vinylpyrrolidone, 1.8g allyl polyoxyethylene methyl ether, 9.1g allyl polyoxyethylene epoxy ether, 43.6g bisallyl polyether (average molecular weight is 4000) was dissolved in 390.0g of ethanol, nitrogen gas was introduced, then the temperature was raised to 75°C, 10.0g of azobisisobutyronitrile was added, stirred evenly, and reacted for 1 hour to obtain the first intermediate;

[0070] (2) (3) Same as Example 1, to prepare corrosion inhibitor 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com