Method for preparing plant tissue protein by wet extrusion

A plant tissue and protein technology, applied in the field of protein preparation, can solve the problems of brittle tissue protein structure, poor storage performance, heavy beany smell, etc., to improve toughness and storage performance, good storage performance, and remove beany smell Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 composite protein

Embodiment 2

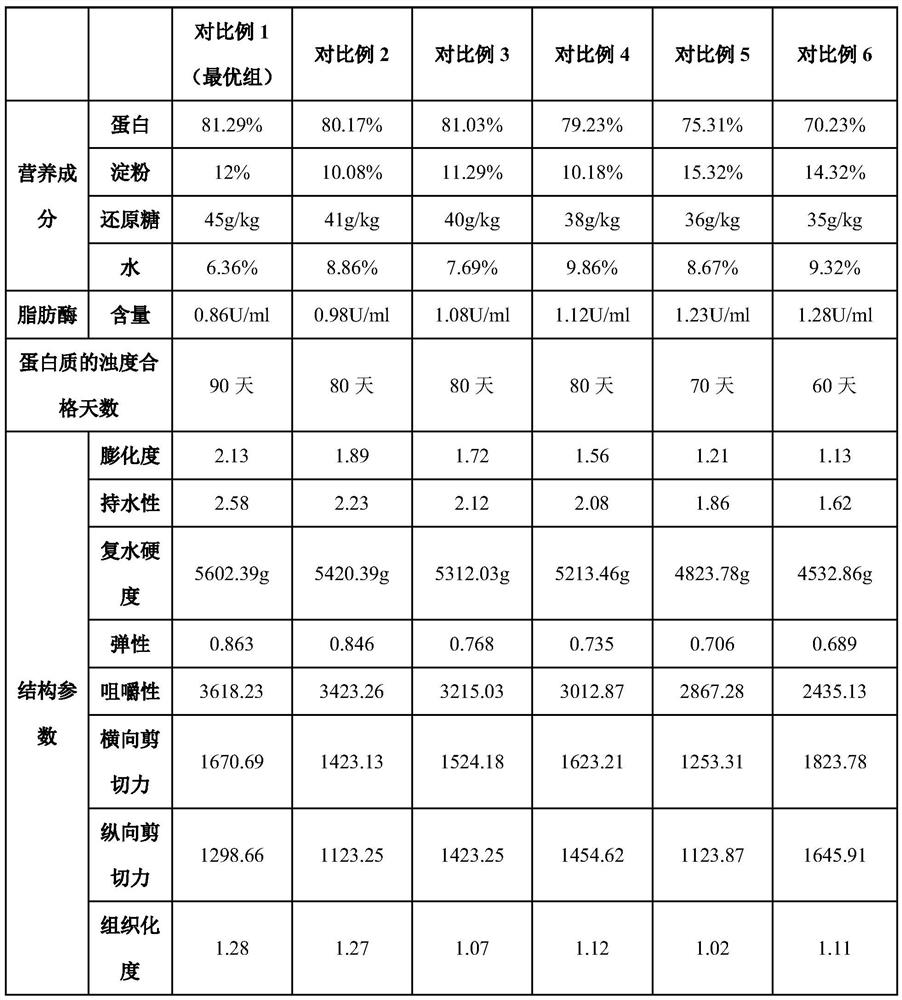

[0068] Example 2 The detection of the content of each component of the finished product proves that the nutritional components are balanced

[0069] According to the spectrophotometric method in the national standard GB5009.5-2016, detect the protein content in the plant composite tissue protein; according to the national standard GB 5009.9-2016, detect the starch content in the plant composite tissue protein; according to the national standard GB 5009.7- In 2016, the potassium permanganate titration method was used to detect the reducing sugar content in the plant composite tissue protein; according to the national standard GB 5009.3-2016, the direct drying method was used to detect the water content in the plant composite tissue protein.

[0070] The test results show: taking comparative example 1 as an example, in the plant composite tissue protein, the protein content is 81.29%; the starch content is 12%; the reducing sugar content is 45g / kg; Protein nutrients, composition...

Embodiment 3

[0071] Example 3 lipase content detection proves the removal effect of beany smell

[0072] The enzyme activity detection steps are as follows

[0073] Pre-treatment: Pass the raw material and crushed product through a 200-mesh sieve, accurately weigh 2 g of the sample to be tested and put it into a centrifuge tube, add 50 mL of sodium borate buffer solution with a pH of 9.0, shake fully for 20 min, centrifuge at 5000 r / min for 10 min, and take the supernatant liquid for use.

[0074] Substrate preparation: Accurately weigh 700mg of linoleic acid, 700mg of Tween 20 and 5mL of deoxygenated distilled water in a suitable beaker, shake repeatedly to make it uniform, avoid bubbles, add 5.5mL 0.5moL / L NaOH to make the system clear Transparent solution, add deoxygenated distilled water to make up volume in 250ml volumetric flask for later use.

[0075] Buffer solution preparation: Preparation of sodium borate buffer solution (0.2mol / L, pH 9.0): Mother liquor A: 0.2mol / L boric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com