Vegetable protein pork intestine and production method thereof

A plant protein and production method technology, applied in the field of bionic food, can solve problems such as high cholesterol, health and safety concerns in the processing process, excessive fat, etc., and achieve the effects of continuous production process, chewy taste characteristics, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

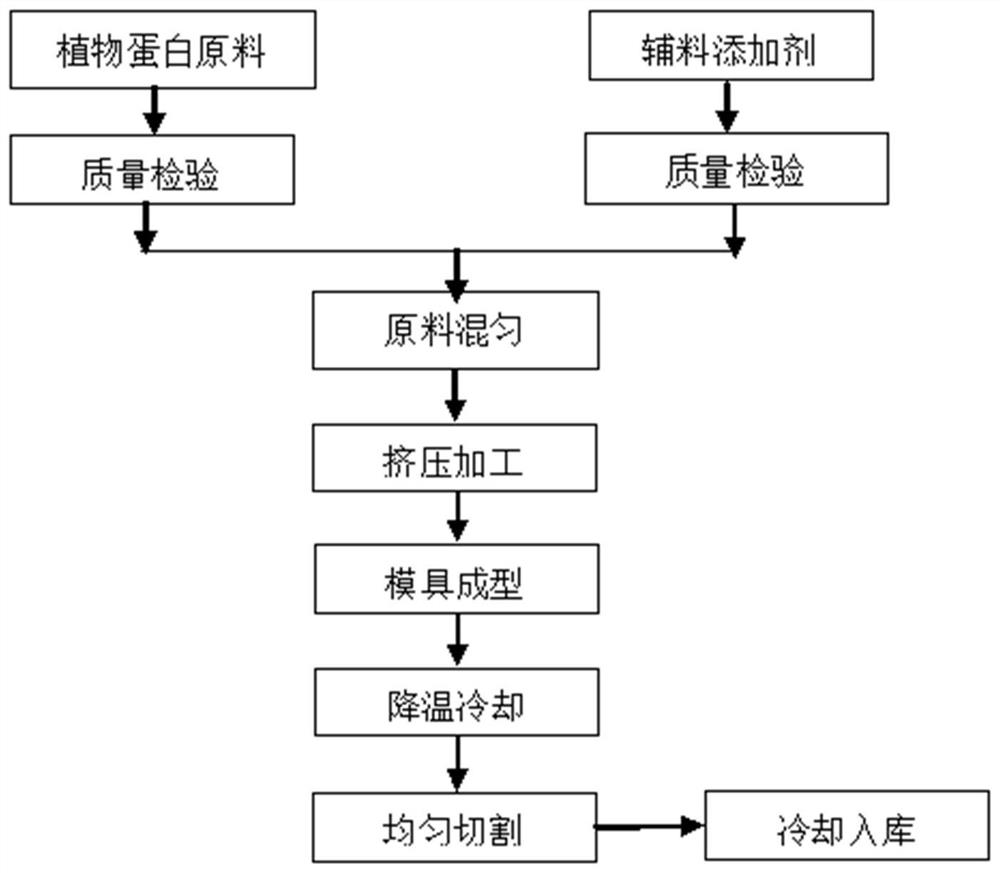

[0035] The present embodiment provides a kind of production method of vegetable protein sausage, such as figure 1 As shown, the steps are as follows:

[0036] (1) Raw material preparation:

[0037] Mix soybean protein isolate and wheat protein at a weight ratio of 4:1 to ensure that the crude protein content in the mixed raw materials is not less than 80%, and the nitrogen solubility index is not less than 40%;

[0038] Add an auxiliary material additive composed of yeast extract, beany smell masking agent, and sausage essence in a weight ratio of 5:2:2 in a weight ratio of 0.2%, and then mix step by step to obtain a mixed material;

[0039] (2) extrusion:

[0040] Using a twin-screw extruder, the mixed material is evenly fed through the feeder, and water is added online through a constant flow pump;

[0041] Synchronously adjust the feeding speed of the extruder to 30g / min, the moisture content of the product to 50%, the screw speed to 150 rpm and the barrel temperature to...

Embodiment 2

[0049] This embodiment provides a method for producing vegetable protein fatty sausage, the steps are as follows:

[0050] (1) Raw material preparation:

[0051] Mix low-temperature soybean protein, wheat protein, and pea protein in a weight ratio of 3:3:4 to ensure that the crude protein content in the mixed raw materials is not less than 65%, and the nitrogen solubility index is not less than 30%;

[0052] Add the excipient additive consisting of yeast extract, beany smell masking agent and sausage essence in a weight ratio of 5:2:2 at a weight ratio of 0.5%, and then mix them step by step;

[0053] (2) extrusion:

[0054] Using a twin-screw extruder, the mixed material is evenly fed through the feeder, and water is added online through a constant flow pump;

[0055] Synchronously adjust the feeding speed of the extruder to 20g / min, the moisture content of the product to 55%, the screw speed to 200 rpm and the barrel temperature to 150°C to ensure that the extruded product...

Embodiment 3

[0060] This embodiment provides a method for producing vegetable protein fatty sausage, the steps are as follows:

[0061] (1) Raw material preparation:

[0062] Mix soybean protein concentrate, peanut protein, and hemp seed protein in a weight ratio of 6:3:1 to ensure that the crude protein content in the mixed raw materials is not less than 70%, and the nitrogen solubility index is not less than 30%;

[0063] Add an auxiliary material additive consisting of yeast extract, beany smell masking agent, and sausage essence in a weight ratio of 5:2:2 at a weight ratio of 0.8%, and then mix them step by step;

[0064] (2) extrusion:

[0065] Using a twin-screw extruder, the mixed material is evenly fed through the feeder, and water is added online through a constant flow pump;

[0066] Synchronously adjust the feeding speed of the extruder to 40g / min, the moisture content of the product to 55%, the screw speed to 180 rpm and the barrel temperature to 145°C to ensure that the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com