Modified biomass-based composite adsorption material for treating radioactive pollutants

A composite adsorption material and composite material technology are applied in the field of modified biomass-based composite adsorption materials and their preparation, which can solve the problems of ecological environment pollution, large consumption, global warming, etc., and achieve high treatment efficiency and high recycling efficiency. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

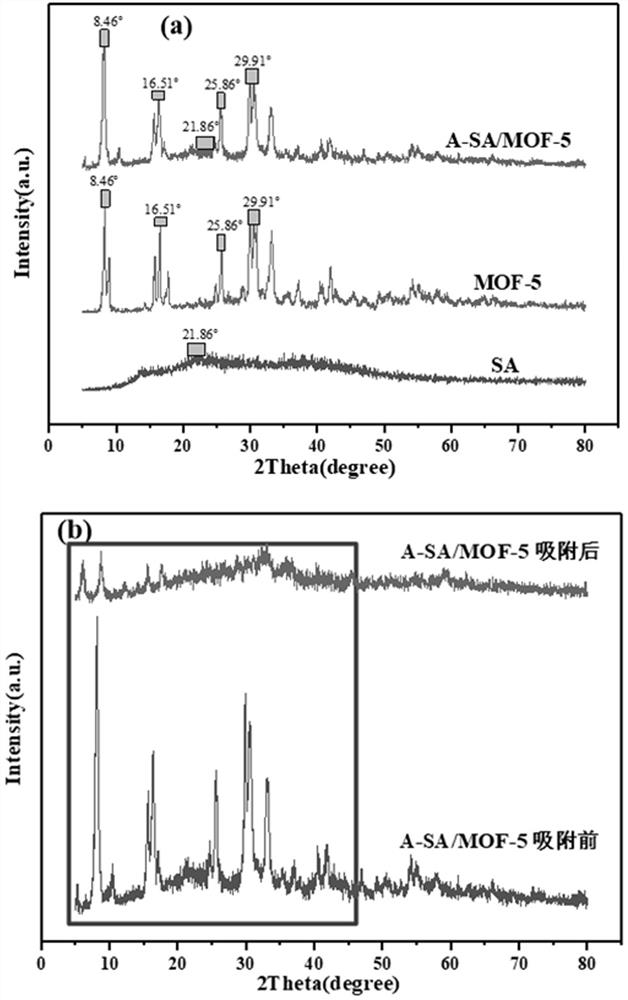

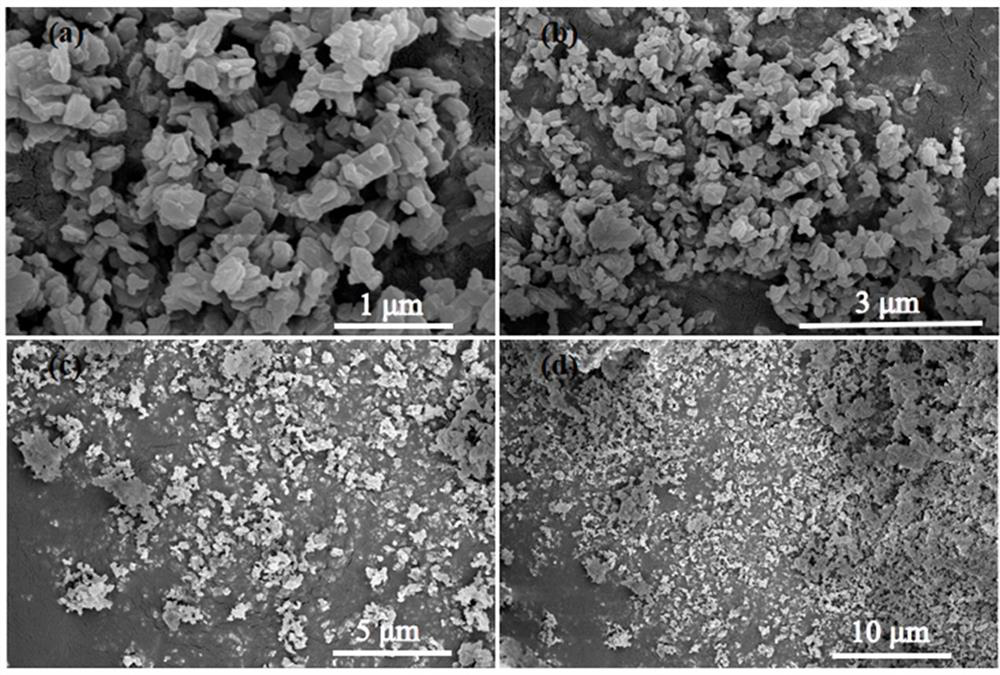

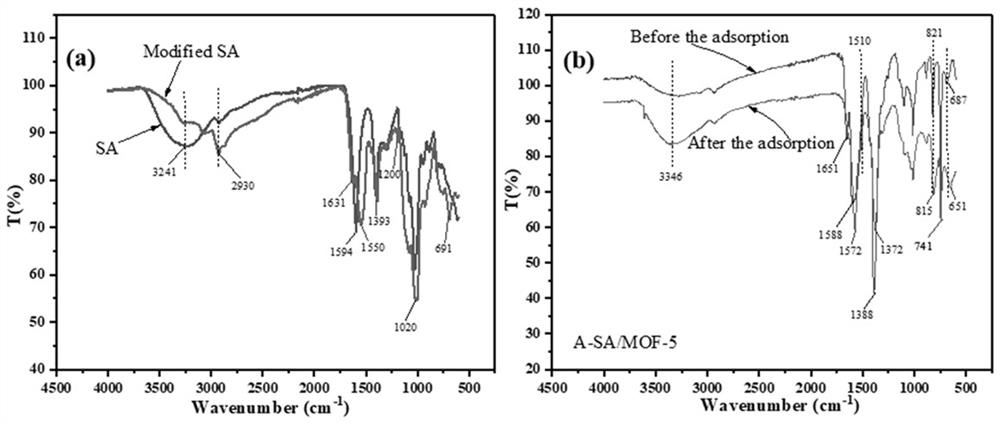

[0038] The simple in-situ synthesis method preparation process provided by the present invention synthesizes the method for A-SA / MOF-5 adsorbent, and the steps are as follows:

[0039] (1) Fully mix 1.5 g sodium alginate, 50 mL N,N-dimethylformamide and 5 mL ultrapure water as solution A;

[0040] (2) Thoroughly mix 1.75 mL 3-aminopropyltriethoxysilane and 60 mL N,N-dimethylformamide as solution B;

[0041] (3) After stirring for 1 hour, pour solution B into solution A and continue to mix and stir for 5 hours;

[0042] (4) Washing with ethanol three times, and then obtaining the modified SA solid powder after vacuum freeze-drying;

[0043] (5) Disperse 0.2 g of modified SA and 0.4 g of zinc nitrate hexahydrate simultaneously in 20 mL of N,N-dimethylformamide mixed solution and stir for 30 min;

[0044] (6) In addition, 0.12 g of terephthalic acid was dispersed in a mixed solution of 1.0 mL of triethylamine and 20 mL of N,N-dimethylformamide and stirred for 30 min;

[0045] (7...

Embodiment 2

[0053] This example shows a composite material A-SA / MOF-5 as an adsorbent to treat UO in uranium-containing wastewater 2 2+ study on the adsorption properties.

[0054] The present invention uses A-SA / MOF-5 as adsorbent, UO 2 2+ As an adsorption object, explore the different mass ratios of the carrier and the load in the composite material, the amount of the adsorbent, the initial pH, the influence of the coexisting ions, the recycling rate, the adsorption temperature and the UO 2 2+ Initial concentration equal to UO 2 2+ The influence of adsorption performance and the law of influence, the adsorption isotherm model and the adsorption kinetic model were fitted, and the optimal adsorption conditions were explored, laying a sufficient foundation for the efficient removal of uranium pollution.

[0055] (1) Take 4 Erlenmeyer flasks, weigh 25 mg of SA before and after modification, MOF-5, and A-SA / MOF-5 with a mass ratio of 1:1, and add them to 50 mL of unadjusted pH at a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com