Strong-alkality anion exchange resin for amphoteric homogeneous mixed bed and preparation method of strong-basicity anion exchange resin

An exchange resin and strong basic technology, which is applied in the field of strong basic anion exchange resin for amphoteric homogeneous mixed bed and its preparation, can solve the problems of huge market consumption, improve the density of functional groups, shorten the production cycle, improve the Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A preparation method for an amphoteric homogeneous mixed bed strong basic anion exchange resin, characterized in that it comprises the following steps:

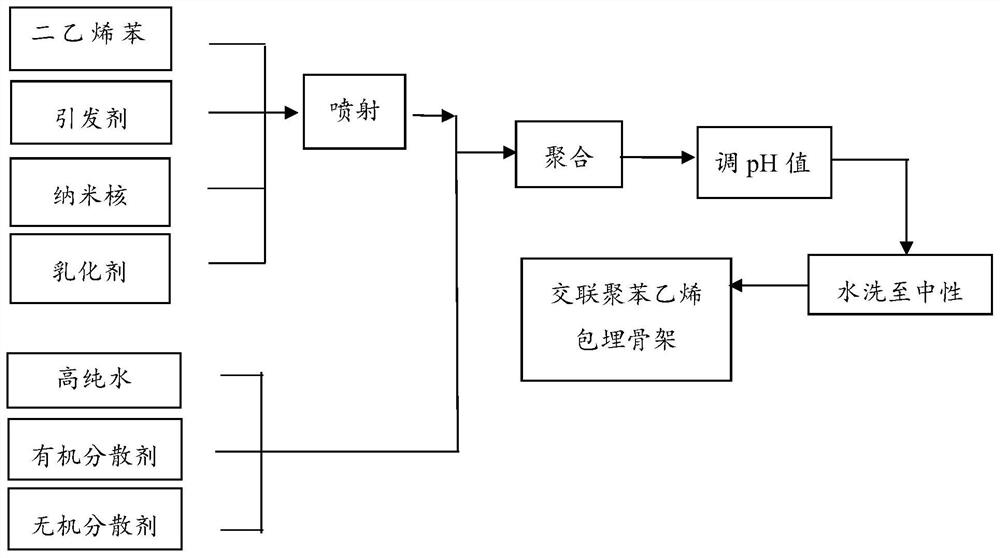

[0075] (1) Reference figure 1 , weigh 88% styrene, 8% divinylbenzene, 0.1% nano-nucleus, 0.05% emulsifier, 0.6% initiator and other liquid monomers according to the mass fraction, mix them evenly in proportion, and spray them into the dispersed Stir in the aqueous solution of the solvent for 0.5-3h at a stirring speed of 120-180rpm, polymerize into spherical particles of 0.3-0.6mm, then solidify the spherical particles at 75±5°C for 6-10h, and finally wash with water at 95°C for 3 hours - After 5 times, a cross-linked polystyrene-embedded framework was obtained.

[0076] in,

[0077] The nano core includes: nano titanium dioxide;

[0078] Initiators include: potassium persulfate, benzoyl peroxide;

[0079] Emulsifiers include: sodium dodecylbenzenesulfonate, ethylene oxide;

[0080] The aqueous dispersant solution...

Embodiment 2

[0083] A preparation method for an amphoteric homogeneous mixed bed strong basic anion exchange resin, characterized in that it comprises the following steps:

[0084] (1) Reference figure 1 , Weigh 92% styrene, 12% divinylbenzene, 0.3% nano-core, 0.2% emulsifier, 1.2% initiator and other liquid monomers by mass fraction, mix them evenly in proportion, and spray them into the dispersed Stir in the aqueous solution of the solvent for 0.5-3h at a stirring speed of 120-180rpm, polymerize into spherical particles of 0.3-0.6mm, then solidify the spherical particles at 75±5°C for 6-10h, and finally wash with water at 95°C for 3 hours - After 5 times, a cross-linked polystyrene-embedded framework was obtained.

[0085] in

[0086] The nano core includes: nano zirconia;

[0087] Initiators include: Benformyl peroxide;

[0088] Emulsifiers include: sodium dodecylbenzenesulfonate;

[0089] The aqueous dispersant solution includes the following raw materials in mass fractions: 3% ge...

Embodiment 3

[0092] A preparation method for an amphoteric homogeneous mixed bed strong basic anion exchange resin, characterized in that it comprises the following steps:

[0093] (1) Reference figure 1 , weigh 90% styrene, 10% divinylbenzene, 0.2% nano-core, 0.12% emulsifier, 0.9% initiator and other liquid monomers according to the mass fraction, mix them evenly in proportion, and spray them into the dispersed Stir in the aqueous solution of the solvent for 0.5-3h at a stirring speed of 120-180rpm, polymerize into spherical particles of 0.3-0.6mm, then solidify the spherical particles at 75±5°C for 6-10h, and finally wash with water at 95°C for 3 hours - After 5 times, a cross-linked polystyrene-embedded framework was obtained.

[0094] in

[0095] The nano core includes: nano silicon dioxide;

[0096] Initiators include: benzoyl peroxide;

[0097] Emulsifiers include: sodium lauryl sulfate, propylene oxide;

[0098]The aqueous dispersant solution includes the following raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com