Preparation method of polyaniline material with three-dimensional hierarchical micro-nano structure

A technology of hierarchical micro-nano structure and polyaniline, which is applied in the field of preparation of micro-nano structure polyaniline materials, can solve the problems of toxicity, difficulty in meeting the large-scale preparation of micro-nano structure polyaniline, poor electrical conductivity of polyaniline, etc., and achieves easy access to raw materials. high conductivity, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

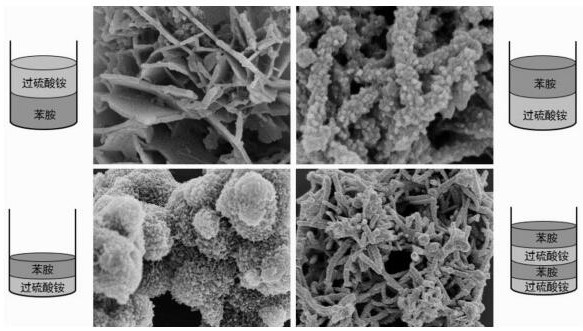

[0035] Polyaniline with hierarchical structure was prepared by ice interfacial polymerization (see figure 1 ). Weigh 0.9128g of aniline and add it to 20ml of a mixed solution of 1.0M hydrochloric acid and dodecylbenzenesulfonic acid (the amount of hydrochloric acid is 90%) to prepare an acidic solution of aniline with a concentration of 0.2M, and weigh 0.3244g of ferric chloride Add 0.2762g of peroxybenzoic acid to 20ml of 1.0M hydrochloric acid and dodecylbenzenesulfonic acid mixed solution (the amount of hydrochloric acid is 90%), and prepare ferric chloride and peroxybenzoic acid with a concentration of 0.2M. Solution; the acidic solution of aniline monomer is placed in a glass container, the liquid surface area is 10cm 2 , frozen into ice; then the solution of ferric chloride and peroxybenzoic acid was pre-cooled in an ice bath, poured on the ice surface of aniline, and frozen into ice; finally, the ice cubes were transferred to an ice bath for polymerization for 12 hours...

Embodiment 2

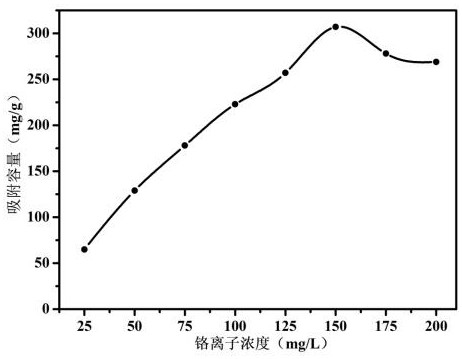

[0037] Polyaniline with hierarchical structure was prepared by ice interfacial polymerization (see figure 1 ). Weigh 1.141g of aniline and add it to 10ml of 1.0M phosphoric acid solution to prepare aniline acidic solution with a concentration of 0.5M; weigh 0.4658g of ammonium persulfate and add it to 10ml of 1.0M phosphoric acid solution to prepare a concentration of Ammonium persulfate acidic solution; the acidic solution of ammonium persulfate is placed in a glass container with a liquid surface area of 25cm 2 , frozen into ice; then the aniline monomer solution was pre-cooled in an ice bath, poured on the ice surface of ammonium persulfate, and frozen into ice; finally, the ice cubes were transferred to an ice bath for polymerization for 8 hours to obtain polyaniline with a hierarchical structure . The sea urchin-like structure of polyaniline (such as Figure 4 shown). The prepared polyaniline was formulated into a 2.0 mg / ml aqueous dispersion, and 5.0 μL of the solu...

Embodiment 3

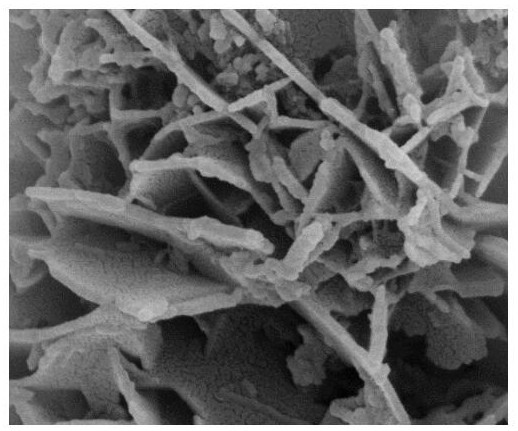

[0039] Polyaniline with hierarchical structure was prepared by ice interfacial polymerization (see figure 1 ). Weigh 0.9128g of aniline and add it to 20ml of 2.0M mixed solution of sulfuric acid and p-benzenesulfonic acid (the amount of sulfuric acid is 90%) to prepare an aniline acidic solution with a concentration of 0.2M. Weigh 0.3726g of ammonium persulfate and add it to 20ml of In the mixed solution of 2.0M sulfuric acid and p-benzenesulfonic acid (the amount of sulfuric acid is 90%), an acidic solution of ammonium persulfate with a concentration of 0.2M is prepared; the acidic solution of ammonium persulfate is placed in a glass container, and the liquid surface area is 30cm 2 , frozen into ice; then the aniline monomer solution was pre-cooled in an ice bath, poured on the ice surface of ammonium persulfate, and frozen into ice; finally, the ice cubes were transferred to an ice bath for polymerization for 6 hours to obtain polyaniline with a hierarchical structure . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com