Biomass solid wastewater thermal pretreatment coupling gasification method based on regulation and control of microcrystalline structure

A technology of microcrystalline structure and biomass, applied in the field of biomass resource treatment, can solve the problems of difficult conversion, change of crystallinity, influence on gasification characteristics, etc., and achieve the effects of increasing production, improving gasification characteristics and increasing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

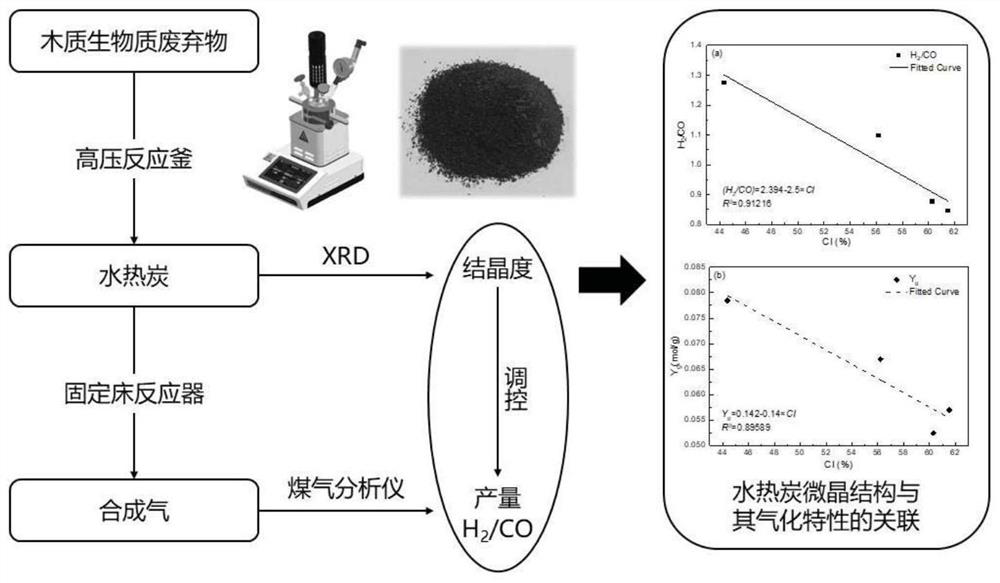

[0030] A method of thermal pretreatment coupled gasification of biomass solid waste water based on regulation and control of microcrystalline structure in this embodiment can be referred to figure 1 , including the following steps:

[0031] (1) Hydrothermal pretreatment: Weigh the solid waste material and water into the autoclave, fill it with nitrogen to replace the original air in the autoclave and seal it, put the autoclave on the heating table, set the hydrothermal temperature and residence time , cooling after the reaction, washing, filtering and drying the product to obtain hydrothermal charcoal;

[0032] (2) Characterization of hydrothermal charcoal: use X-ray diffractometer to scan to obtain the XRD diffraction pattern of hydrothermal charcoal, and perform peak fitting on the XRD diffraction pattern to calculate the crystallinity of hydroth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com