Preparation method of sulfur modified polyacrylonitrile material

A polyacrylonitrile and sulfur modification technology, which is applied in the preparation/purification of sulfur, carbon preparation/purification, chemical instruments and methods, etc., can solve the problem that the rate characteristics of sulfur-modified polyacrylonitrile composite materials are not enough for power batteries , The quality of polyacrylonitrile powder is different, etc., to achieve the effect of improving capacity and rate characteristics, improving electrochemical performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of sulfur-modified polyacrylonitrile material, comprising the following steps:

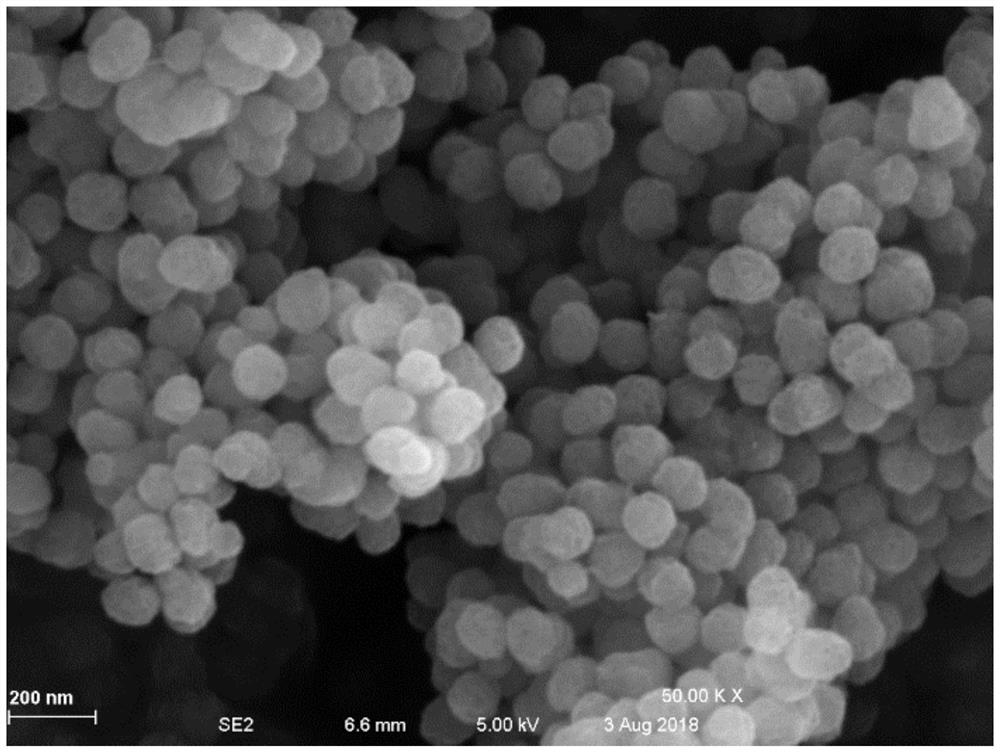

[0031] In step S1, mixing the acrylonitrile monomer and the emulsifier in deionized water to obtain a first mixed solution, and then adding an initiator for initiating the polymerization reaction to generate polyacrylonitrile solid particles and vacuum drying to obtain polyacrylonitrile solid particles;

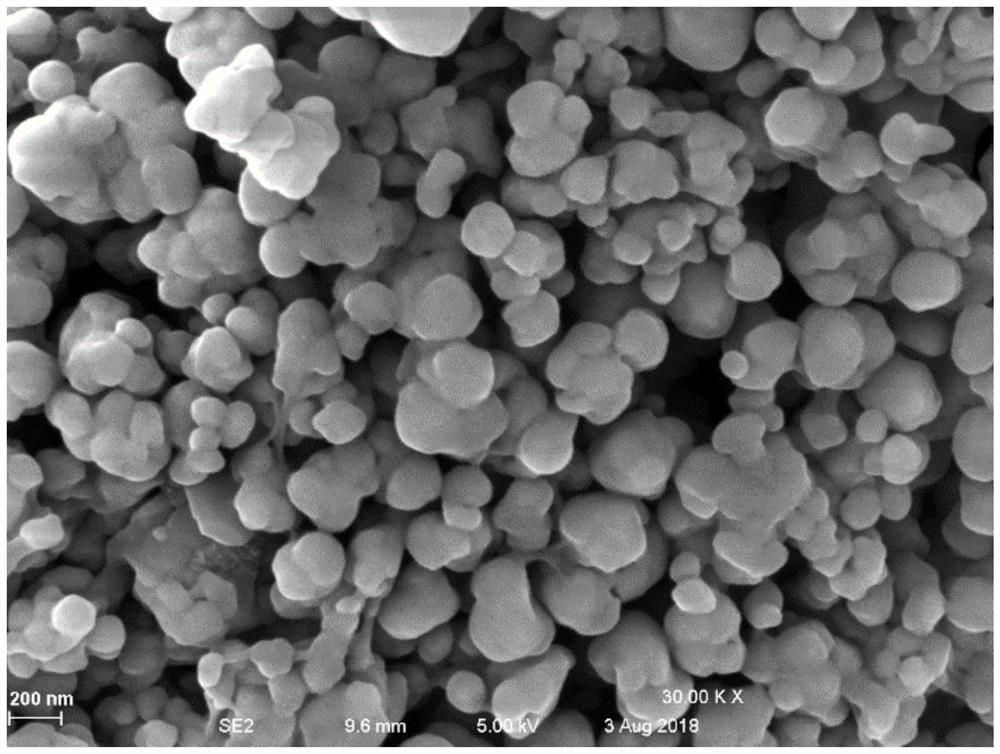

[0032] In step S2, mixing polyacrylonitrile solid particles and sublimated sulfur powder in a ball mill tank to obtain a sulfur-polyacrylonitrile mixture;

[0033] In step S3, under nitrogen protection, the sulfur-polyacrylonitrile mixture is heated for carbonization reaction, and the sulfur-modified polyacrylonitrile material is obtained after cooling.

[0034] The preparation method of a sulfur-modified polyacrylonitrile material of the present invention uses acrylonitrile monomers, emulsifiers and initiators to obtain polyacrylonitrile solid particles through the me...

Embodiment 1

[0046] The synthesis of step S1 polyacrylonitrile:

[0047] S1.1 Weigh 20g of acrylonitrile monomer, 1.8g of sodium lauryl sulfate, and 160g of deionized water into the reaction flask and stir evenly to obtain the first mixed liquid. The stirring time is about 30 minutes. Weigh 0.15 g of ammonium persulfate and dissolve it in 20 g of deionized water to make an initiator solution, and add the initiator solution into a constant pressure funnel. It should be noted that the polymerization of acrylonitrile belongs to free radical polymerization, and the initiator solution cannot be added to the flask together with acrylonitrile monomer and sodium lauryl sulfate as an emulsifier, because directly adding ammonium persulfate is easy to cause If the concentration of the initiator in the inner solution is too high, the local polymerization reaction will be violent and exothermic, especially the free radical polymerization self-acceleration phenomenon will be easily strengthened, which w...

Embodiment 2

[0058] Steps S1-S2 are the same as steps S1-S2 in embodiment 1, and the difference from embodiment 1 is in step S3.

[0059] In step S3, 20 g of the ground mixture was weighed and placed in a quartz tube, and heated at 450° C. for 6 hours under nitrogen protection (carbonization process), and a black sulfur-modified polyacrylonitrile material was obtained after natural cooling.

[0060] After testing, the 0.1C cycle for 3 weeks, the discharge gram capacity reached 1288.9mAh·g-1, the capacity retention rate after 0.5C cycle for 80 cycles was 80.1%, and the rate characteristic 1C capacity retention rate was 95.6%.

[0061] As an organic polymer with high nitrogen content, polyacrylonitrile material itself does not have electrical conductivity, but carbonized polyacrylonitrile material has certain electrical conductivity, which is attributed to the molecular structure of polyacrylonitrile material after carbonization. Pyridine ring structure linked composition. The carbonization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com