Repairing and plugging material and preparation method thereof

A technology of plugging material and composite cementitious material, which is applied in the field of repairing plugging materials and their preparation, can solve the problems of slow hardening, slow strength development, poor anti-seepage and plugging performance of the plugging material, and achieves good anti-seepage performance and durability, improved safety and service life, good structural consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

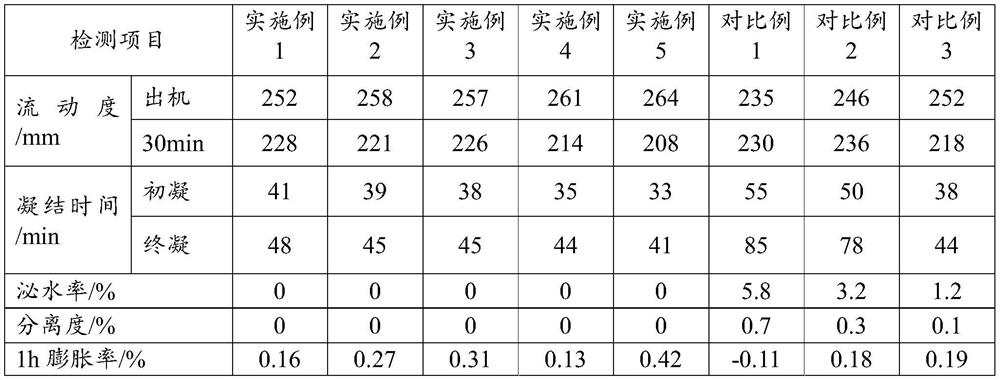

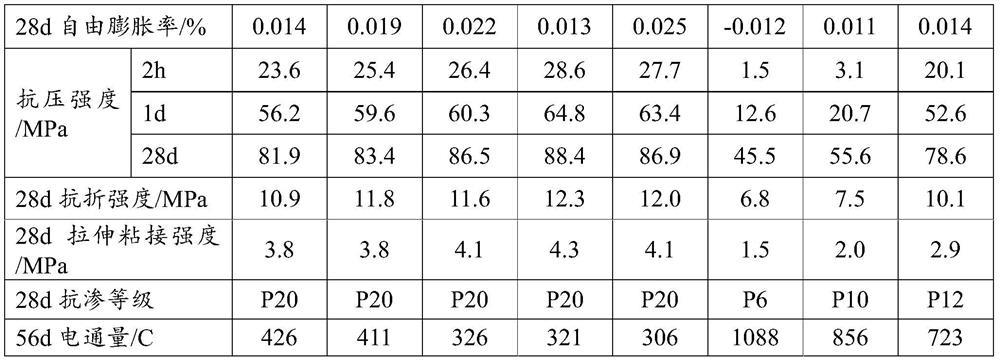

Examples

preparation example Construction

[0043] Another object of the present invention is to provide a kind of preparation method of above-mentioned repairing plugging material, comprising the following steps:

[0044] S1. Mix the enhanced composite mineral admixture, composite expansion component, rheological agent, water reducer, defoamer, anti-seepage water repellent, coagulant and active reinforcing component to prepare a premix ;

[0045] S2. Add composite cementitious material to the premixed material, stir evenly, and obtain repairing and plugging material.

[0046] It also includes the step of: stirring the repairing and plugging material and mixing water into a slurry, and performing the repairing and plugging construction; wherein, the water-material ratio of the mixing water and the repairing and plugging material is in the range of 0.28 to 0.34.

[0047] The repairing and plugging material prepared by the present invention is specially used for repairing and plugging leaks caused by structural concrete ...

Embodiment 1

[0051] This embodiment provides a preparation method for repairing leakage plugging material, comprising the following steps:

[0052] 1) Weigh each raw material according to the ratio, each raw material and its dosage include: 65kg of composite cementitious material (56.875kg of sulphoaluminate cement, 8.125kg of ordinary Portland cement), 24.155kg of enhanced composite mineral admixture (tuff 12.0775kg, metakaolin 9.662kg, talc 2.4155kg), composite expansion component 5.5kg (calcined magnesia 5.375kg, azodicarbonamide 0.125kg), rheology agent 0.25kg (hydrated magnesium aluminum silicate 0.05kg, hydrogenated Castor oil thixotrope 0.2kg), water reducer 0.55kg, defoamer 0.06kg, anti-seepage water repellent 0.085kg, coagulant 0.4kg (lithium carbonate 0.1kg, aluminum sulfate 0.15kg, calcium formate 0.15kg) , 4kg of active enhancing components;

[0053] 2) Put the weighed enhanced composite mineral admixture, composite expansion component, rheology agent, water reducer, defoamer,...

Embodiment 2

[0055] This embodiment provides a kind of preparation method of repairing leakage plugging material, and the difference with embodiment 1 is:

[0056] In step 1), each raw material and its consumption include: 68kg of composite cementitious material (61.2kg of sulphoaluminate cement, 6.8kg of ordinary Portland cement), 21.25kg of enhanced composite mineral admixture (10.625kg of tuff, partial Kaolin 6.375kg, talc 4.25kg), composite expansion component 7.0kg (calcined magnesia 6.86kg, azodicarbonamide 0.14kg), rheological agent 0.36kg (hydrated magnesium aluminum silicate 0.12kg, hydrogenated castor oil thixotropic Glue 0.24kg), water reducer 0.64kg, defoamer 0.07kg, impervious water repellent 0.08kg, coagulant 0.6kg (lithium carbonate 0.3kg, aluminum sulfate 0.2kg, calcium formate 0.1kg), activity enhancement group Divide 2kg;

[0057] In step 2), add 33kg water in the repair plugging material;

[0058] Other steps are the same as participating in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com