Method for synthesizing n-butyl isocyanate by adopting micro-channel reactor

A technology of microchannel reactor and n-butyl isocyanate, applied in chemical instruments and methods, preparation of isocyanic acid derivatives, chemical/physical/physicochemical reactors, etc., can solve unstable yield and product quality , FNC heating instability, long reaction time and other problems, to achieve excellent mass and heat transfer effects, improve phosgene utilization, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

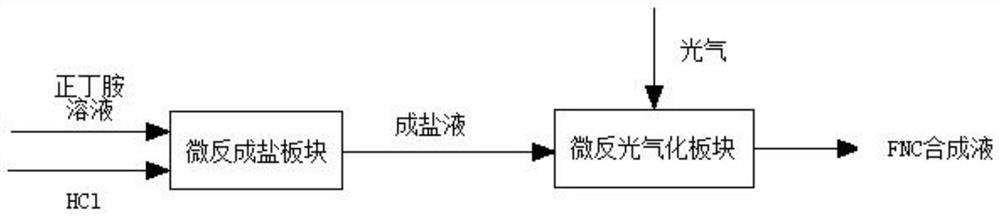

[0036] Such as figure 1 As shown, prepare 10% n-butylamine-o-dichlorobenzene liquid, and pass the n-butylamine-o-dichlorobenzene liquid and hydrogen chloride into the microchannel reactor simultaneously according to the hydrogen chloride and n-butylamine molar ratio of 1.2:1 to form a salt, The salt-forming temperature is 20°C, and the residence time is 50s; (2) n-butylamine hydrochloride-o-dichlorobenzene liquid and phosgene are continuously passed into the phosgenation plate for phosgenation reaction, phosgene: n-butylamine hydrochloride The salt molar ratio is 1.3:1. By adjusting the back pressure valve at the outlet of the reactor, the pressure of the reaction system was kept at 0.5 MPa, the reaction temperature was controlled at 95° C. by the heat exchanger, and the residence time was 100 s. The synthetic solution obtained by the reaction was sent to the sample for analysis. The normalized content of FNC in the synthetic solution was 99.2%, and the yield of FNC was 98.1%...

Embodiment 2

[0038] Such as figure 1 As shown, prepare 5% n-butylamine-chlorobenzene liquid, according to hydrogen chloride and n-butylamine molar ratio is 1.1:1, pass n-butylamine-chlorobenzene liquid and hydrogen chloride in the microchannel reactor simultaneously and carry out salt formation, and salt formation temperature 10°C, residence time 200s. (2) The n-butylamine hydrochloride-chlorobenzene solution and phosgene are continuously passed into the phosgenation plate for phosgenation reaction, and the molar ratio of phosgene: n-butylamine hydrochloride is 1.2:1. By adjusting the back pressure valve at the outlet of the reactor, the pressure of the reaction system was kept at 0.30MPa, the reaction temperature was controlled at 120°C by the heat exchanger, and the residence time was 300s. The synthetic liquid was obtained after the reaction, and the sample was sent for analysis after being drained. The normalized content of FNC in the synthetic liquid is 98.5%, and the yield of FNC is...

Embodiment 3

[0040] Such as figure 1 As shown, prepare 15% n-butylamine-toluene solution, and pass the n-butylamine-toluene solution and hydrogen chloride into the microchannel reactor at the same time according to the molar ratio of hydrogen chloride and n-butylamine as 1.5:1 to form a salt, and the salt-forming temperature is 30°C , dwell time 100s. (2) The n-butylamine hydrochloride-toluene liquid and phosgene are continuously passed into the phosgenation plate for phosgenation reaction, and the molar ratio of phosgene: n-butylamine hydrochloride is 1.5:1. By adjusting the back pressure valve at the outlet of the reactor, the pressure of the reaction system was kept at 0.20MPa, the reaction temperature was controlled at 110°C by the heat exchanger, and the residence time was 200s. The synthetic liquid was obtained after the reaction, and the sample was sent for analysis after being drained. The normalized content of FNC in the synthetic liquid is 99.5%, and the yield of FNC is 98.7%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com