Silicone sealant as well as preparation method and production line thereof

A silicone sealant and production line technology, applied in chemical instruments and methods, adhesives, mixers, etc., can solve the problems of uneven local reaction of the sealant, adverse effects on the quality and mechanical properties of the silicone sealant, etc. The effect of production efficiency, good processing performance and uniform system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

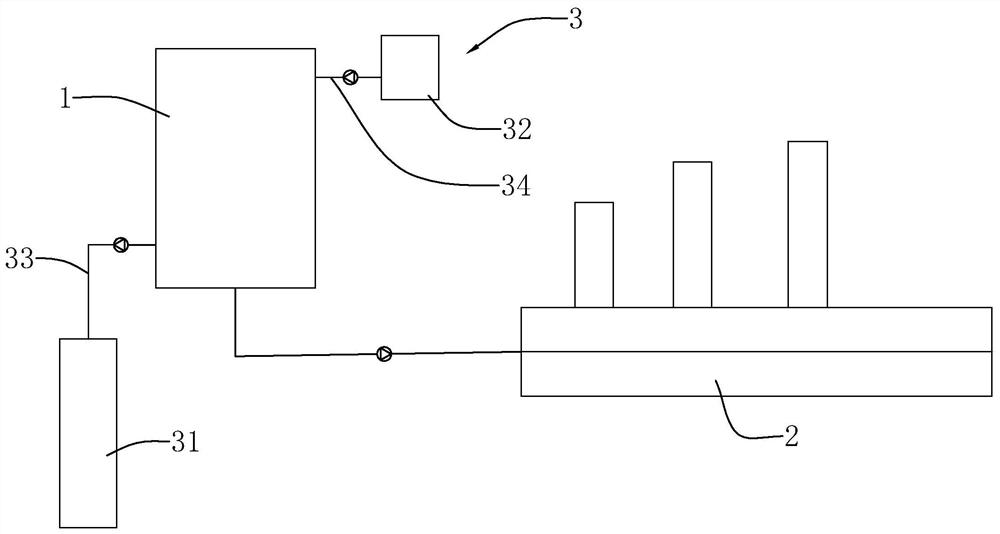

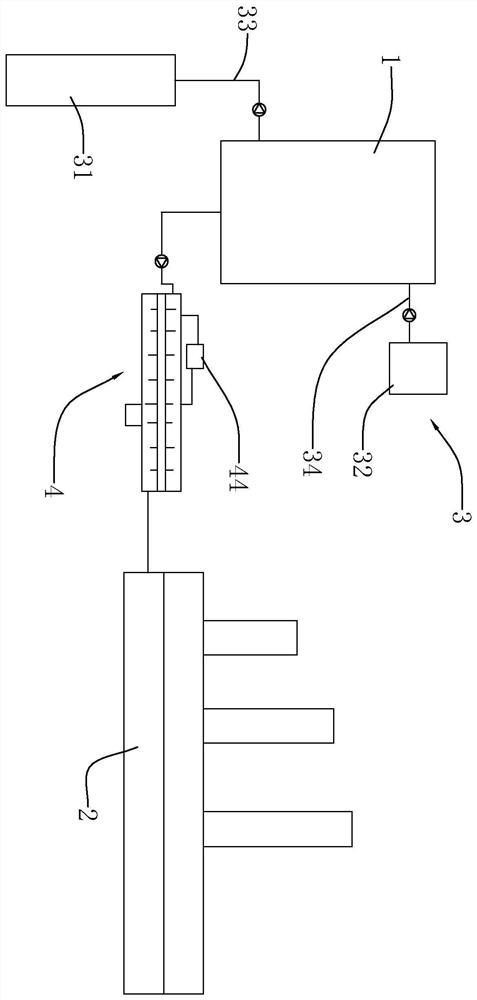

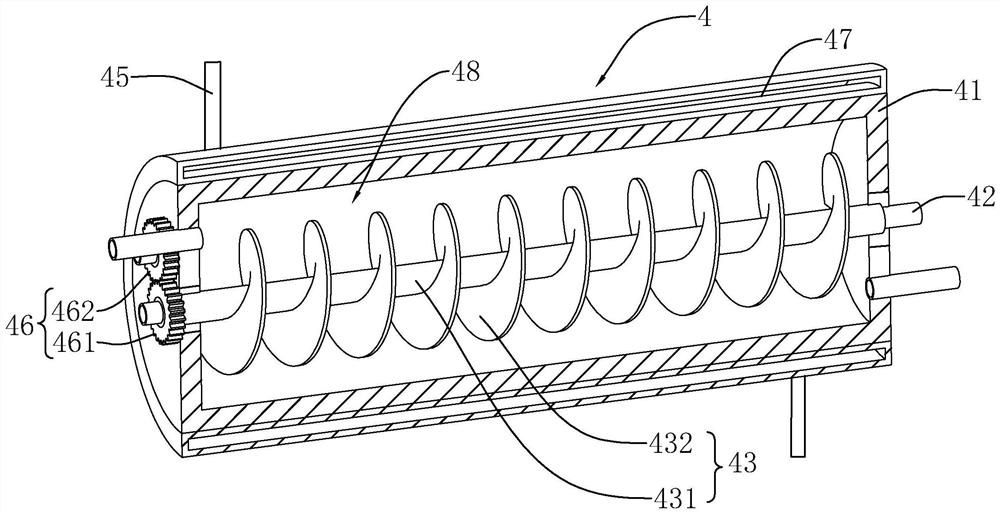

[0054] Embodiment 1, a kind of production line of silicone sealant, refer to figure 1 , including a dynamic mixing mechanism 1, a static mixing mechanism 2 and a protection mechanism 3, connecting pipelines are arranged between the discharge end of the dynamic mixing mechanism 1 and the feeding end of the static mixing mechanism 2, and valves are arranged on the connecting pipelines. Wherein, the dynamic stirring mechanism 1 is a vertical planetary gear kneader. The static mixing mechanism 2 is a LXJTH-200 static mixer. In the production line, all connecting pipelines are provided with insulation layers (not shown on the way), and the insulation layers are insulation cotton wound on the surface of the connecting pipelines.

[0055] refer to figure 1 , The protection mechanism 3 includes an air intake device 31 and an air extraction device 32 . The air inlet device 31 is connected to the dynamic stirring mechanism 1 through the air inlet pipe 33, and the air inlet device 31 ...

Embodiment 1-1

[0057] Example 1-1, a silicone sealant, prepared through the production line as in Example 1, the preparation method is as follows:

[0058] S1. Pump through the protection mechanism 3 for at least three times, and remove the air from the dynamic stirring mechanism 1, and then add 12kg of high-viscosity silicone rubber, 1.5kg of low-viscosity silicone oil, and 12kg of filler into the dynamic stirring mechanism 1 under vacuum. Stirring at 110° C. for 2 h to obtain the first mixed system;

[0059] S2. Naturally lower the temperature of the first mixing system to 20°C, pressurize the first mixing system into the static mixing system through the air inlet device 31, and uniformly add 1kg of ketoxime crosslinking agent and 0.1kg of silane to the static mixing system within 30 minutes After the coupling agent is added, continue to mix for 30 minutes, mix evenly, discharge and pack to obtain silicone glue.

[0060] Among them, the high-viscosity silicone rubber is 107 silicone rubbe...

Embodiment 1-2

[0062] Example 1-2, a silicone sealant, differs from Example 1-1 in that the amount of high-viscosity silicone rubber is 10.5 kg, the amount of filler is 10 kg, the amount of low-viscosity silicone oil is 3 kg, and the amount of ketone oxime The consumption of coupling agent is 0.9kg, and the consumption of silane coupling agent is 0.3kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com