Dechlorination method for high-chlorine raw material hydrogenation process

A hydrogenation process and raw material technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as stress corrosion, pinhole corrosion, pitting corrosion, crevice corrosion, damage to high-pressure steel equipment, and potential safety hazards , to achieve the effect of improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

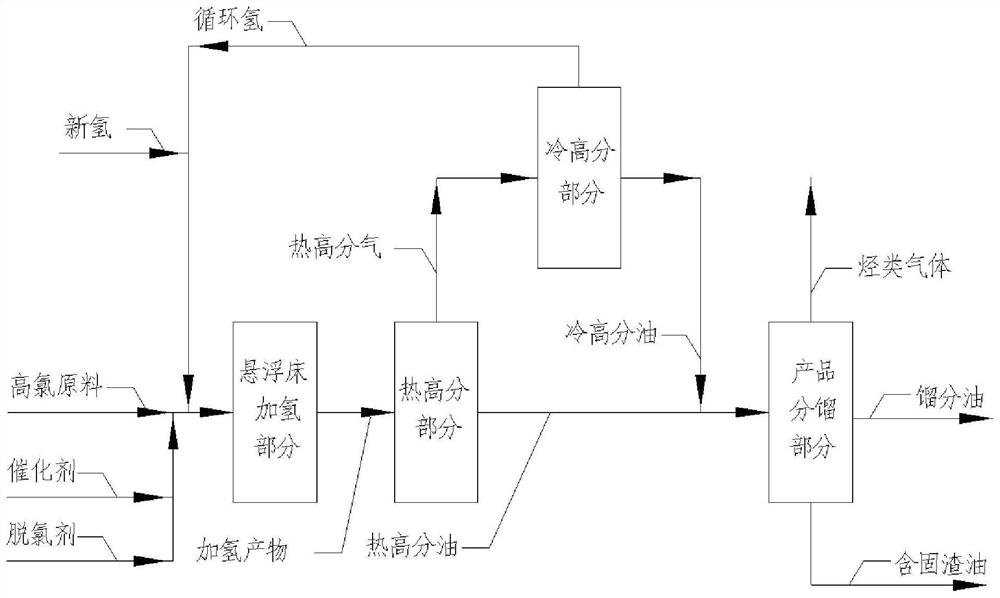

[0018] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended figure 1 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

[0019] The melting point of the present invention refers to the temperature at which a substance is in equilibrium with a solid state and a liquid state under one atmospheric pressure;

[0020] The conventional gaseous hydrocarbons mentioned in the present invention refer to gaseous hydrocarbons under normal conditions, including methane, ethane, propane, and butane.

[0021] The conventional liquid hydrocarbons in the present invention refer to hydrocarbons that are liquid under normal conditions, including pentane and hydrocarbons with higher boiling points.

[0022] The impurity components mentioned in the present invention refer to the conversion products of non-hydrocarbon components in the raw material such as water, am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com