Coal-fired boiler heating surface depth fault early warning system based on industrial internet

An industrial Internet and coal-fired boiler technology, applied in the field of early warning system for deep faults on the heating surface of coal-fired boilers, can solve problems such as shortening the service life of furnace tubes, leakage of furnace tube bursts, and deterioration of furnace tubes, so as to reduce the risk of leakage, The effect of reducing the workload of starting the machine and the pressure of safety accidents and improving the ability of safe and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

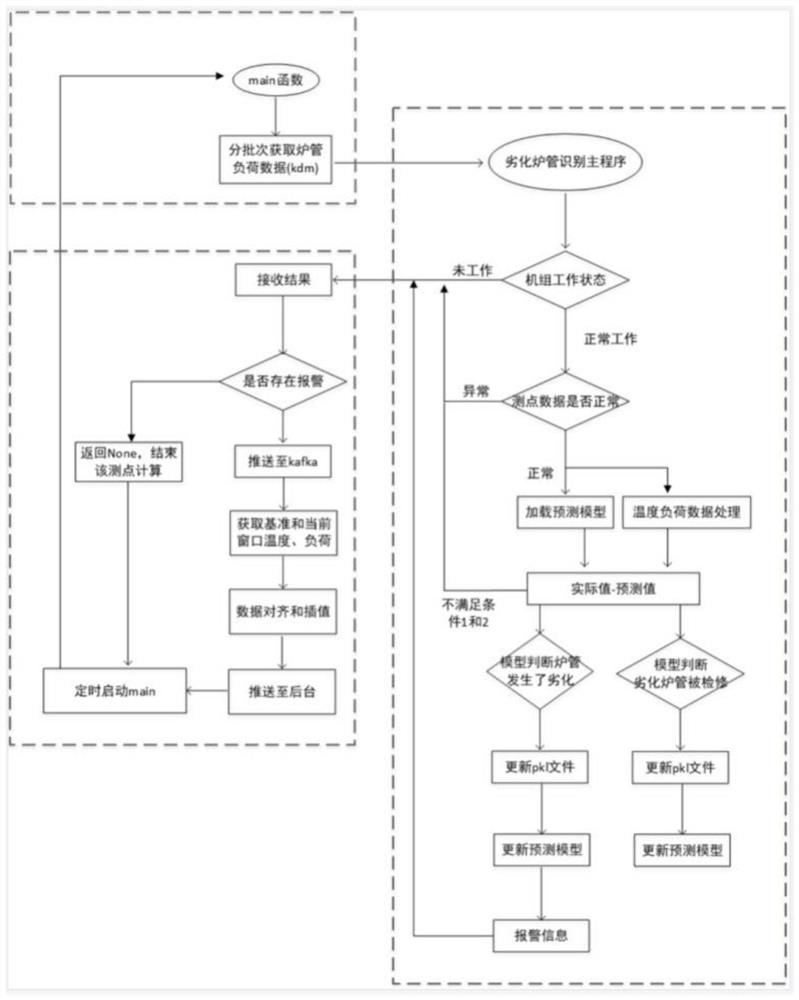

[0041] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

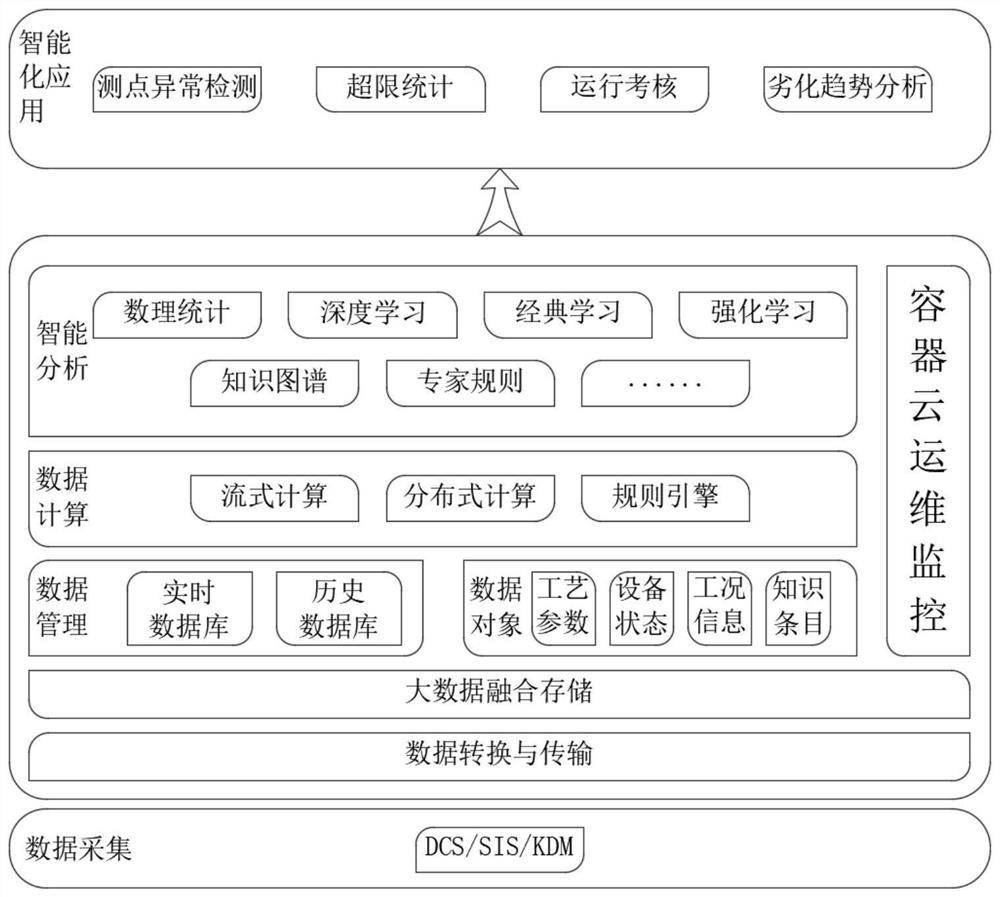

[0042] refer to Figure 1-2 , a coal-fired boiler heating surface depth fault early warning system based on the industrial Internet, including data collection, data conversion and transmission, big data fusion storage, data management, data object, data calculation, intelligent analysis and intelligent application;

[0043] Data acquisition Obtain various data of power plant equipment through DCS / SIS / KDM interface;

[0044] The data conversion and transmission module transmits various equipment data collected by data collection to the data storage module, business module and display module of the monitoring platform;

[0045] Big data fusion storage stores structured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com