Micro-channel plate and preparation method and application thereof

A technology of microchannel plate and prefabricated rod, which is applied in glass manufacturing equipment, manufacturing tools, light-emitting cathode manufacturing, etc., can solve the problem of low pattern noise and achieve uniform gain, low noise, and high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

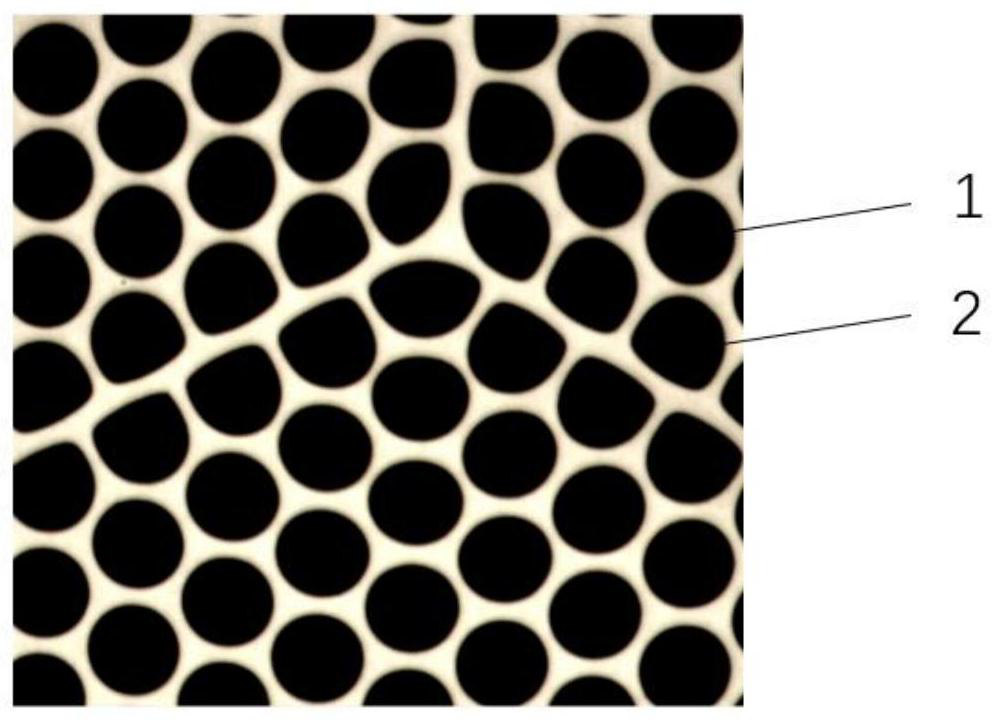

[0040] The invention provides a kind of preparation method of microchannel plate, comprises the following steps:

[0041] Preform Preparation: The preparation of the microchannel plate consists of two glass materials, the channel region material and the channel wall material. The material of the channel area is borosilicate glass, and the composition and ratio include: SiO 2 , 30.3~36.4mol%; B 2 o 3 , 18.9~20.2mol%; La 2 o 3 , 5.9~6.1mol%; the total content of BaO and CaO is, 33.7~39.4mol%; Al 2 o 3 , 1.6~2.3mol%; TiO 2 , 2.0-2.9 mol%, can be dissolved and removed by acid in the subsequent process to form channels. The channel wall material is lead silicate glass, and the composition and ratio include: SiO 2 , 70.5~74.5mol%; PbO, 12.0~12.5mol%; Bi 2 o 3 , 0~2.0mol%; Na 2 O, K 2 O, Rb 2 O and Cs 2 The total content of O is 5.8~7.7mol%; BaO and MgO, 4.6~6.7mol%; Al 2 o 3 , 1.1~3.0mol%; TiO 2 , 0 to 2.0 mol%. The channel wall material is resistant to acid soluti...

Embodiment 1

[0059] The present embodiment provides a kind of preparation method of microchannel plate, comprises the following steps:

[0060] Preform Preparation: The preparation of the microchannel plate consists of two glass materials, the channel region material and the channel wall material. The material of the channel area is borosilicate glass, the composition and ratio are: SiO 2 , 32.0mol%; B 2 o 3 , 18.9mol%; La 2 o 3 , 5.9mol%; BaO, 24.4mol%; Al 2 o 3 , 2.3mol%; CaO, 13.6mol%; TiO 2 , 2.9mol%, and a softening point of 597°C. The channel wall material is lead silicate glass, and the composition and ratio are SiO 2 , 70.5mol%; PbO, 12.5mol%; Bi 2 o 3 , 1.7mol%; Na 2 O, 4.0mol%; Cs 2 O, 3.7mol%; BaO, 3.4mol%, MgO, 1.2mol%; Al 2 o 3 , 3.0mol%, and a softening point of 493°C. Lead silicate glass is processed into cylindrical tubes; borosilicate glass is processed into cylindrical rods.

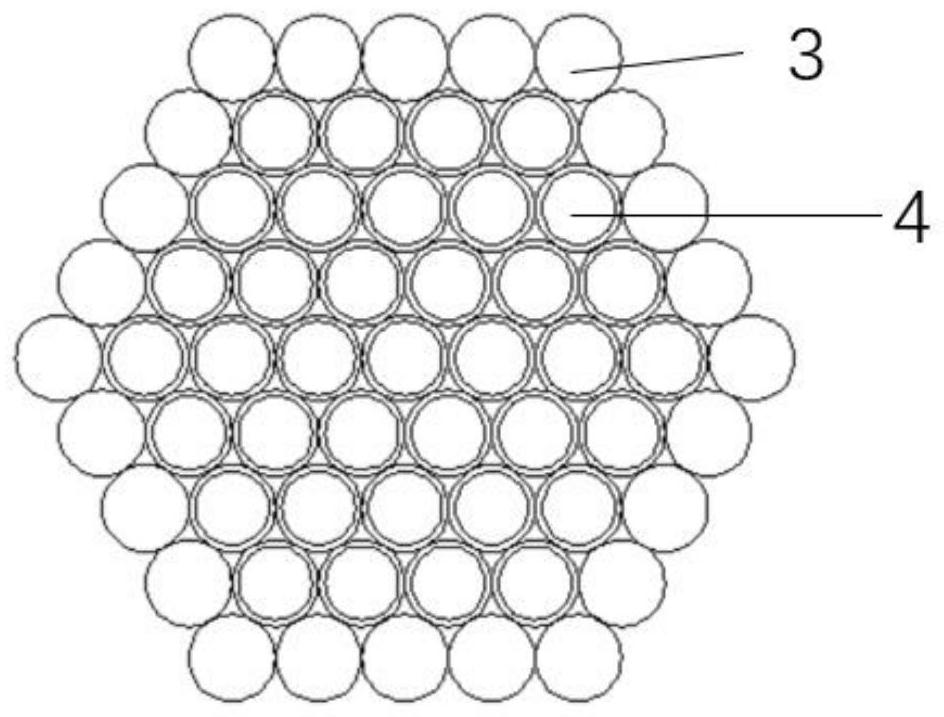

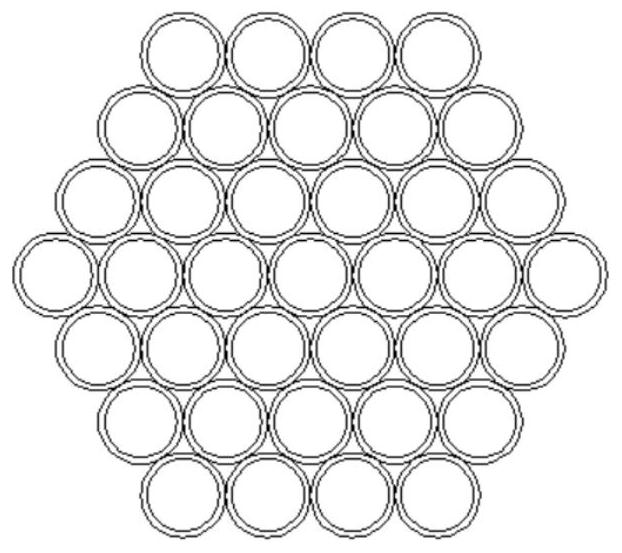

[0061] Monofilament drawing: Nest the borosilicate glass prefabricated rod and t...

Embodiment 2

[0074] The present embodiment provides a kind of preparation method of microchannel plate, comprises the following steps:

[0075] Preform Preparation: The preparation of the microchannel plate consists of two glass materials, the channel region material and the channel wall material. The material of the channel area is borosilicate glass, the composition and ratio are: SiO 2 , 36.4mol%; B 2 o 3 , 20.2mol%; La 2 o 3 , 6.1mol%; BaO, 22.1mol%; Al 2 o 3 , 1.6mol%; CaO, 11.6mol%; TiO 2 , 2.0mol%, and a softening point of 614°C. The channel wall material is lead silicate glass, and the composition and ratio are SiO 2 , 74.5mol%; PbO, 12.0mol%; Bi 2 o 3 , 2.0mol%; Na 2 O, 5.3 mol%; K 2 O, 0.5mol%; BaO, 0.8mol%, MgO, 3.8mol%; Al 2 o 3 , 1.1mol%, and a softening point of 522°C. Lead silicate glass is processed into cylindrical tubes; borosilicate glass is processed into cylindrical rods.

[0076] Monofilament drawing: Nest the borosilicate glass prefabricated rod and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com