Method for efficiently removing nitrogen and carbon from anaerobic effluent of swine wastewater

An anaerobic effluent and anaerobic hydrolysis technology, which is applied in the field of livestock and poultry breeding wastewater treatment, can solve the problems of difficulty in connecting the effluent to municipal sewage pipelines, long residence time, and high operating costs, so as to save aeration energy consumption and have a high degree of automation , The effect of reducing the dosage of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

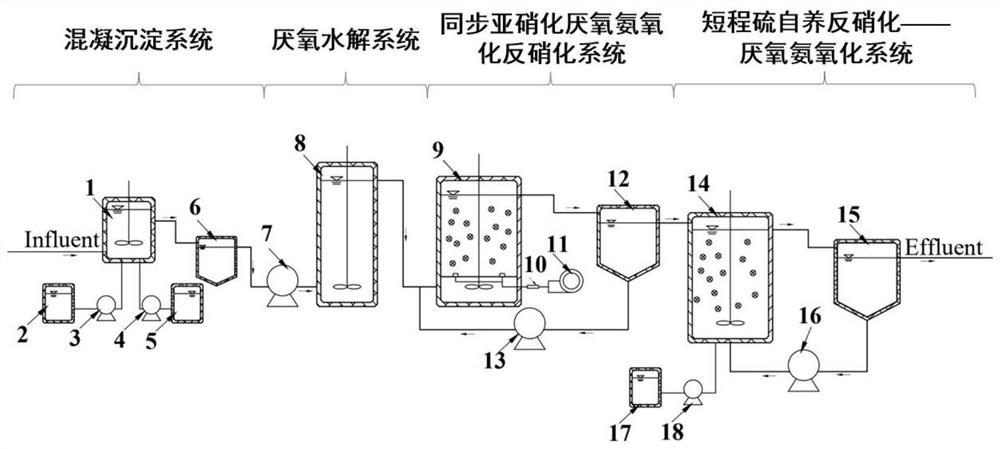

[0028] A method for highly efficient denitrification and carbon removal of pig raising wastewater anaerobic effluent provided by the present invention is implemented in a pig raising wastewater treatment device. The pig raising wastewater treatment device includes a coagulation sedimentation system, an anaerobic hydrolysis system, a synchronization system and short-range systems;

[0029] The coagulation and sedimentation system includes a coagulation stirring tank, a dosing tank, a dosing pump, and a sedimentation tank; PAM (polyacrylamide) and PAC (polyaluminum chloride) in the water inlet and dosing tank are in the coagulation and stirring tank After being fully mixed, it is left to stand in the sedimentation tank, and the water outlet is connected to the anaerobic hydrolysis system, and the sedimentation tank is regularly discharged.

[0030] The anaerobic hydrolysis system includes a water inlet pump and an anaerobic hydrolysis reaction tank; the bottom of the anaerobic h...

Embodiment example

[0036] Adopt method of the present invention to process pig raising waste water, concrete implementation case is as follows:

[0037] The sewage produced after daily cleaning of pig houses in a pig farm is stored for 1 to 2 months and the water quality: NH 4 + -N700~800mg / L or so, COD about 1200mg / L. Applying the process described in the present invention, adopting synchronous nitrosation-anaerobic ammonium oxidation (SNAD) and short-range sulfur autotrophic denitrification-anaerobic ammonium oxidation coupling process, hydraulic retention time 48h, effluent NH 4 + -N less than 10mg / L, NO 2 - - N lower than 1mg / L, NO 3 - - N below 1mg / L, NH 4 + The average removal rate of -N and TN can reach 99%, and the average removal rate of COD is 80.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com