Low-loss LiZnTiMn gyromagnetic ferrite material and preparation method thereof

A technology of gyromagnetic ferrite and low loss, which is applied in the field of low-loss sintered LiZnTiMn gyromagnetic ferrite material and its preparation, which can solve the problem of deteriorating phased array radar system performance and increasing loss of ferrite phase shifter , Increased microwave loss characteristics, etc., to achieve the effect of promoting nucleation and uniform growth, promoting nucleation and grain growth, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

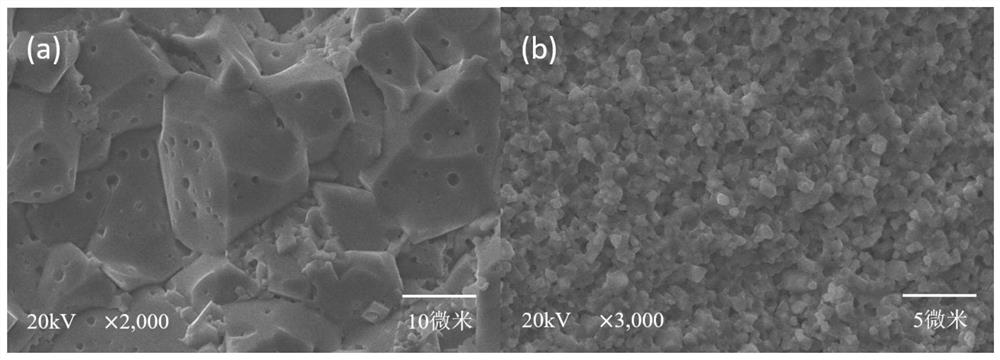

Image

Examples

Embodiment 1

[0019] A preparation method of low-loss LiZnTiMn gyromagnetic ferrite material, comprising the following steps:

[0020] Step 1, with Fe 2 o 3 , ZnO, TiO 2 , Li 2 CO 3 , Mn 3 o 4 as raw material, according to Li 0.42 Zn 0.27 Ti 0.11 mn 0.1 Fe 2.1 o 4 The ratio of the molecular formula is to weigh the raw materials and mix them to obtain the main powder;

[0021] Step 2. Perform a ball mill according to the mass ratio of main powder: water: iron ball = 1:1.5:3. The ball milling time is 6 hours. After the ball milling is completed, take it out and dry it at 100°C. Put the material into the sintering furnace, raise the temperature from room temperature to 800 °C at a heating rate of 2 °C / min and keep it for 2 hours, and then naturally cool down to room temperature with the furnace to obtain the LiZnTiMn main material;

[0022] Step 3. Put Bi 2 o 3 with Nb 2 o 5 The composite sintering aid of composition is added in the main material that step 2 obtains, and where...

Embodiment 2

[0026] Embodiment 2 is compared with embodiment 1, and difference is: the process of step 4 is: add polyvinyl alcohol (PVA) granulation molding and be pressed into blank in the secondary ball abrasive that step 3 obtains, molding pressure is 10Mpa, Then put the blank into the sintering furnace, first raise the heating rate to 450°C at a rate of 2°C / min, keep it for 2 hours, then raise the rate of heating to 920°C at a rate of 2°C / min and sinter for 2 hours. The cooling rate of °C / min is lowered to 600 °C, and then the temperature is naturally lowered to room temperature with the furnace to obtain the low-loss LiZnTiMn gyromagnetic ferrite material.

[0027] The properties of the LiZnTiMn gyromagnetic ferrite material prepared in Example 2 are: sample density: 4.70g / cm 3 ; Saturation magnetic induction: 328mT; Ferromagnetic resonance line width: 161Oe; Coercive force: 152A / m; Squareness ratio: 0.87.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com