In-situ reaction synthesis method of TiC/Ni composite material

An in-situ reaction and composite material technology, applied in the field of composite materials, can solve problems such as high cost, complex process, and equipment limitations, and achieve the effects of increased density, uniform particle distribution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

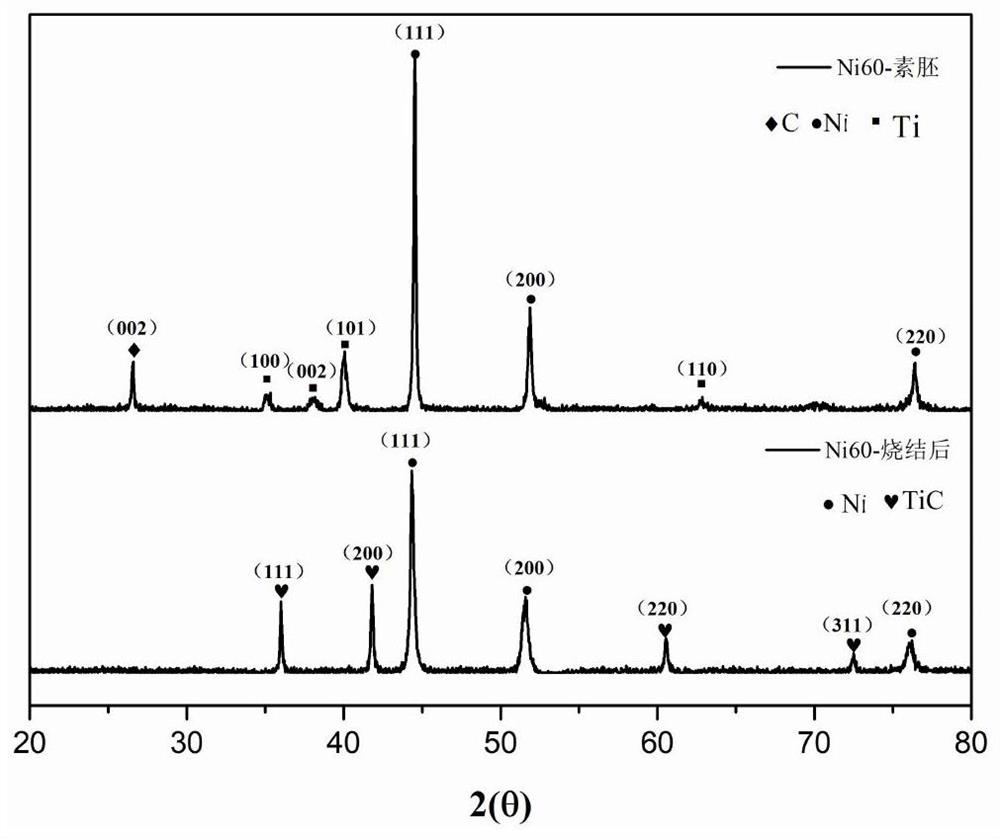

[0034] Embodiment 1: Taking the mass fraction of Ni as 60wt% of the total system as an example

[0035] ① Preparation of mixed powder: Ni powder (purity ≥ 99.9%, particle size 1-3 μm); Ti powder (purity ≥ 99.9%, particle size 1-3 μm); graphite powder (purity ≥ 99.9%, particle size 1-5 μm), three The seed powder and 3wt.% PVB are mixed evenly with a planetary ball mill using ethanol as a solvent;

[0036] ②Body preparation: put the mixed powder obtained in ① into a cylindrical mold with a diameter of 13.00mm, apply a pressure of 4-6MPa, prepare a cylindrical tablet sample with a diameter of 13.00mm, and perform cold isostatic Press molding to prepare green body.

[0037] ③Reaction sintering without pressurization: put the green body obtained in ② into a tube furnace, and pass it into atmospheric pressure argon for atmosphere protection, slowly raise the temperature at a heating rate of 1°C / min, and wait until the temperature in the furnace rises to 1300°C. The TiC / Ni composit...

Embodiment 2

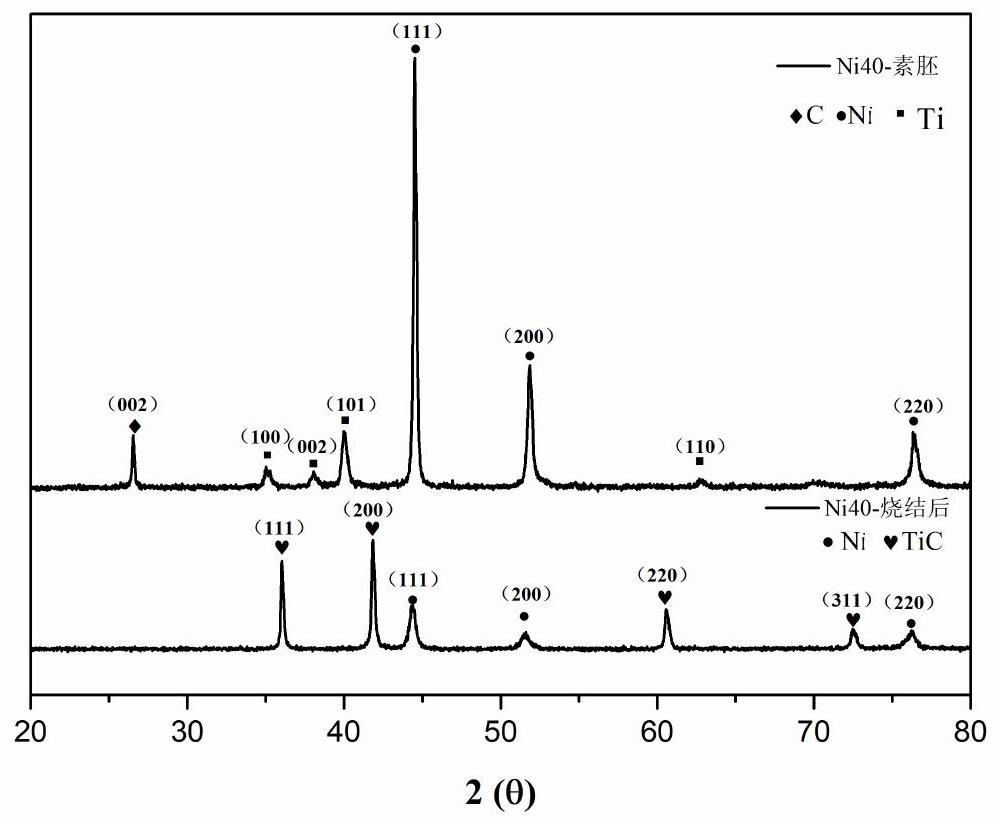

[0041] Embodiment two: take the mass fraction of Ni as 40wt% of the total system as an example

[0042] ① Preparation of mixed powder: Ni powder (purity ≥ 99.9%, particle size 1-3 μm); Ti powder (purity ≥ 99.9%, particle size 1-3 μm); graphite powder (purity ≥ 99.9%, particle size 1-5 μm), three The seed powder and 3wt.% PVB are mixed evenly with a planetary ball mill using ethanol as a solvent;

[0043] ②Body preparation: put the mixed powder obtained in ① into a cylindrical mold with a diameter of 13.00mm, apply a pressure of 4-6MPa, prepare a cylindrical tablet sample with a diameter of 13.00mm, and perform cold isostatic Press molding to prepare green body.

[0044] ③Reaction sintering without pressurization: put the green body obtained in ② into a tube furnace, and pass it into atmospheric pressure argon for atmosphere protection, slowly raise the temperature at a heating rate of 1°C / min, and wait until the temperature in the furnace rises to 1300°C. The TiC / Ni composit...

Embodiment 3

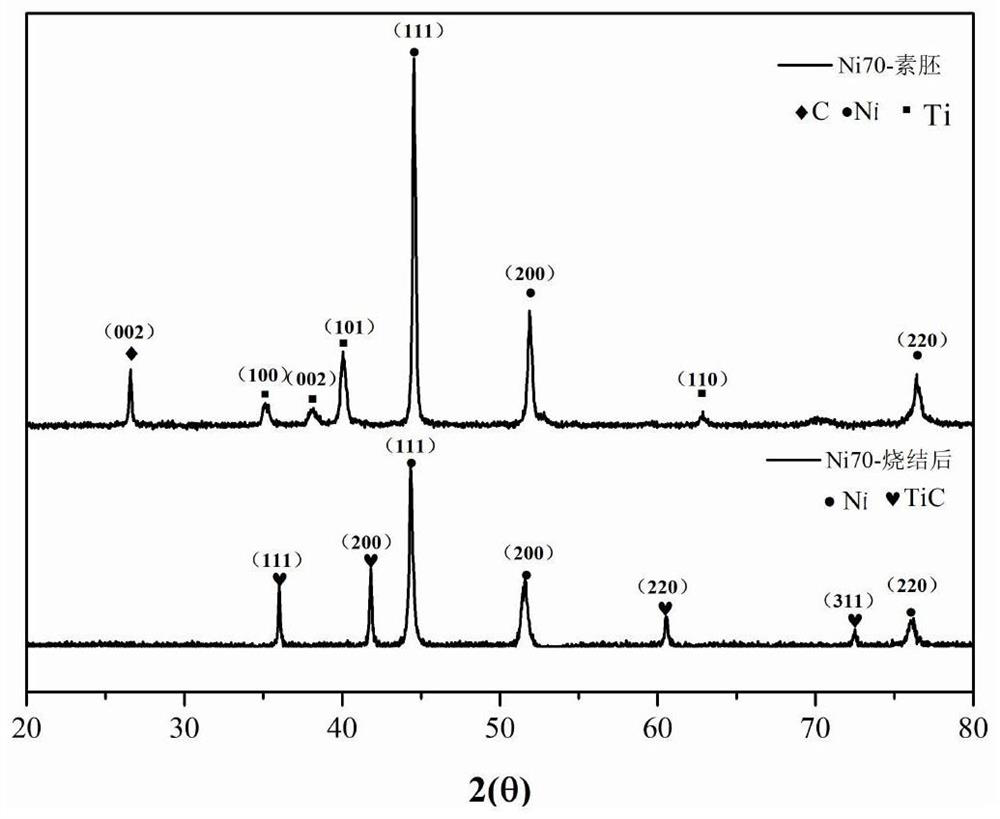

[0048] Embodiment 3: Taking the mass fraction of Ni as 70wt% of the total system as an example

[0049] ① Preparation of mixed powder: Ni powder (purity ≥ 99.9%, particle size 1-3 μm); Ti powder (purity ≥ 99.9%, particle size 1-3 μm); graphite powder (purity ≥ 99.9%, particle size 1-5 μm), three The seed powder and 3wt.% PVB are mixed evenly with a planetary ball mill using ethanol as a solvent;

[0050] ②Body preparation: put the mixed powder obtained in ① into a cylindrical mold with a diameter of 13.00mm, apply a pressure of 4-6MPa, prepare a cylindrical tablet sample with a diameter of 13.00mm, and perform cold isostatic Press molding to prepare green body.

[0051] ③Reaction sintering without pressurization: put the green body obtained in ② into a tube furnace, and pass it into atmospheric pressure argon for atmosphere protection, slowly raise the temperature at a heating rate of 1°C / min, and wait until the temperature in the furnace rises to 1300°C. The TiC / Ni composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com