Method and strain for reducing by-product fumaric acid in L-malic acid fermentation process and application

A fermentation process, malic acid technology, applied in the field of bioengineering, to achieve the effect of reducing by-product fumaric acid and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: Aspergillus niger fum Construction of knockout strains

[0054] This embodiment includes the following steps:

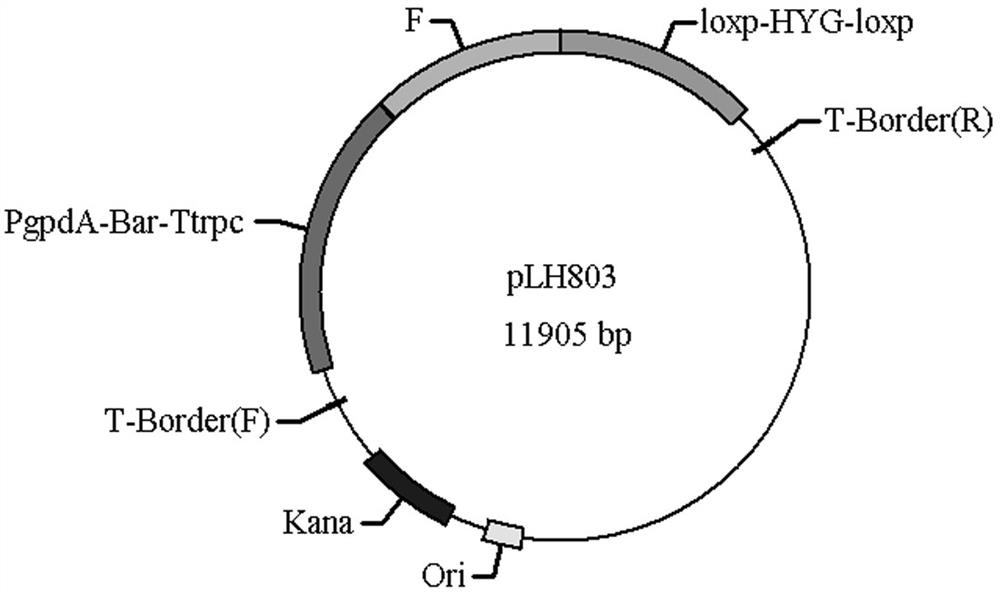

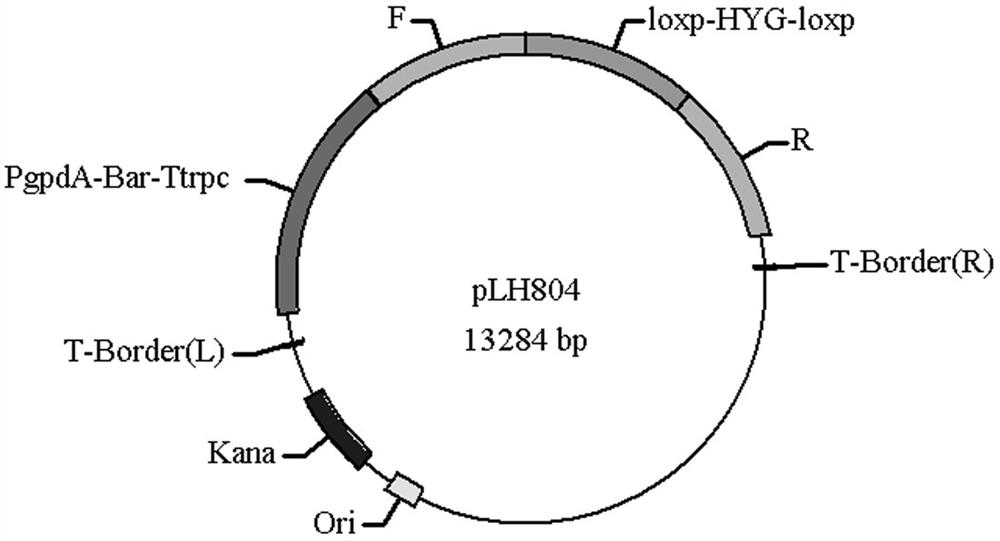

[0055] (1) fum Construction of gene knockout vector

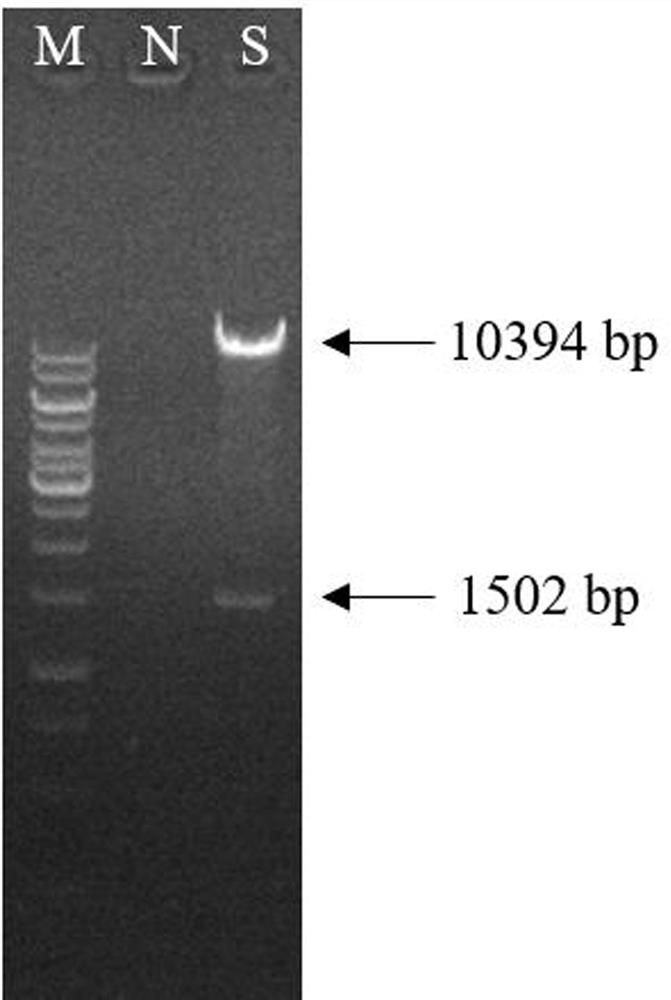

[0056] for amplification fum The upstream sequence fragment of the gene, using the Aspergillus niger genome as a template to design amplification primers fum -F-F and Fum -F-R, recovered by PCR amplification fum The upstream sequence fragment of the gene, via Eco R I and Sac After I double enzyme digestion and gel recovery, it was ligated with the vector pLH594 obtained by the same restriction endonuclease treatment with the help of the One-Step Clone Kit kit, and the ligated product was transformed into E. coli In JM109 competent cells, spread evenly in LB solid medium containing 100 µg / mL kanamycin resistance, culture upside down at 37°C overnight, pick a single clone and verify it by colony PCR and plasmid double enzyme digestion ( figure 2 ), get a successful connecti...

Embodiment 2

[0074] Example 2: Application of engineering strains to produce L-malic acid by fermentation

[0075] Aspergillus niger constructed by the present invention fum The method for producing malic acid by fermentation of gene knockout engineering strain M1 in shake flasks, the specific steps are as follows:

[0076] First, the obtained engineering strain M1 was inoculated on PDA medium and placed in an incubator at 28°C for upside-down culture for 5 days until sufficient conidia were produced;

[0077] The preparation method of the PDA medium: accurately weigh 200 g of peeled potatoes, cut into about 1 cm 3Add distilled water and stir continuously and boil for 30 min, filter and collect the filtrate with double-layer gauze, add 20 g glucose and stir until completely dissolved, distill water to 1 L and divide into jars, autoclave at 121 °C 20 min. Add 1.5% agar to the solid medium.

[0078] Then, the conidia of strain M1 were collected and inoculated in malic acid fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com