Self-disturbance laser additive manufacturing method

A laser additive and manufacturing method technology, applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of complex production equipment and preparation process, difficult to achieve vibration and stirring effect, increase production cost, etc., to reduce porosity , shorten the time required for processing, improve the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

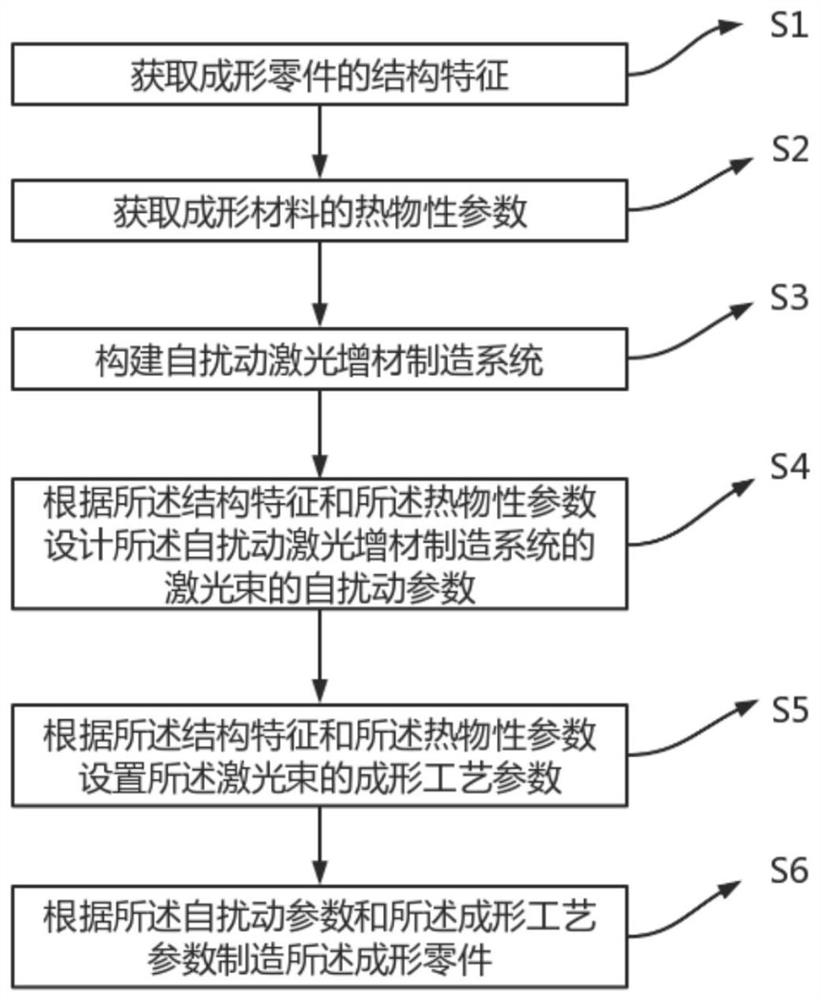

Method used

Image

Examples

Embodiment 1

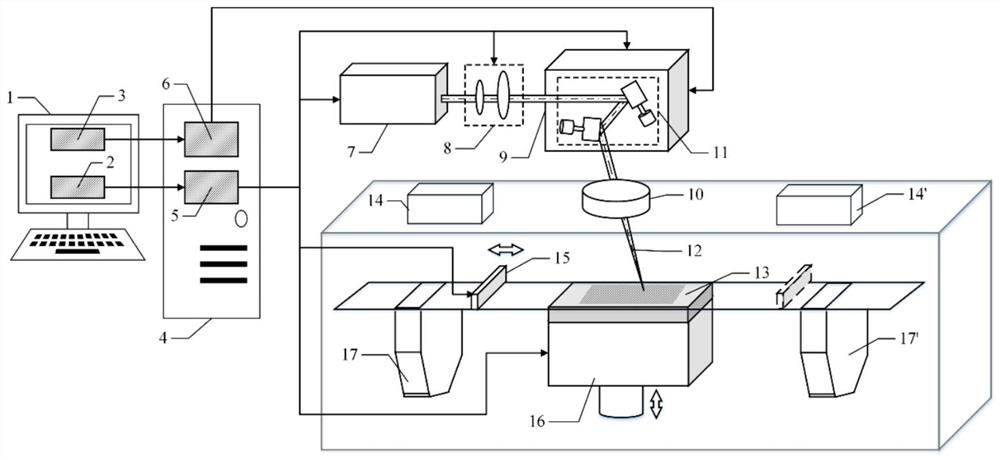

[0123] Such as image 3 As shown, the self-disturbance laser additive manufacturing system provided by the present invention is a two-way powder spreading method, and the self-disturbance laser additive manufacturing system includes a system software 1, a controller 4, a laser 7, a beam expander 8, and a scanning galvanometer 9 , focusing mirror 10, substrate 13, first and second powder feeding devices 14, 14', powder spreading device 15, forming cylinder 16 and first and second powder recovery devices 17, 17'. System software 1 includes forming process parameter control software 2 and self-disturbance parameter control software 3, controller 4 includes forming process parameter controller 5 and self-disturbance parameter controller 6, wherein forming process parameter control software 2 and forming process parameter controller 5 It is used to set forming process parameters such as laser power P, scanning distance H, phase angle θ, and motion parameters such as layer thickness...

Embodiment 2

[0130] Such as Figure 4 As shown, the self-disturbance laser additive manufacturing system provided by the present invention is a two-way powder spreading method, and the self-disturbance laser additive manufacturing system includes a system software 1, a controller 4, first and second lasers 7, 7', a second 1. Second beam expanders 8, 8', first and second scanning galvanometers 9, 9', first and second focusing mirrors 10, 10', substrate 13, first and second powder feeding devices 14, 14', powder spreading device 15, forming cylinder 16, and first and second powder recovery devices 17, 17'. The system software 1 includes a forming process parameter control software 2 and a self-disturbance parameter control software 3 , and the controller 4 includes a forming process parameter controller 5 and a self-disturbance parameter controller 6 . Among them, the forming process parameter control software 2 is connected with the forming process parameter controller 5, and is used to se...

Embodiment 3

[0138] The Ti-43Al-9V-0.5Y(at.%) alloy thin-walled sample was prepared by using the above-mentioned single-beam self-disturbance laser additive manufacturing system. The scanning strategy was circular periodic disturbance, and the length of the sample was 10mm. The test raw material is Ti-43Al-9V-0.5Y (at.%) alloy powder blown by gas atomization, and the particle size of the powder is 15-53 μm. In order to ensure the fluidity of the powder, the alloy powder was kept in a vacuum oven at 100 °C for 1 h before the test. The self-disturbance laser additive manufacturing method comprises the following steps:

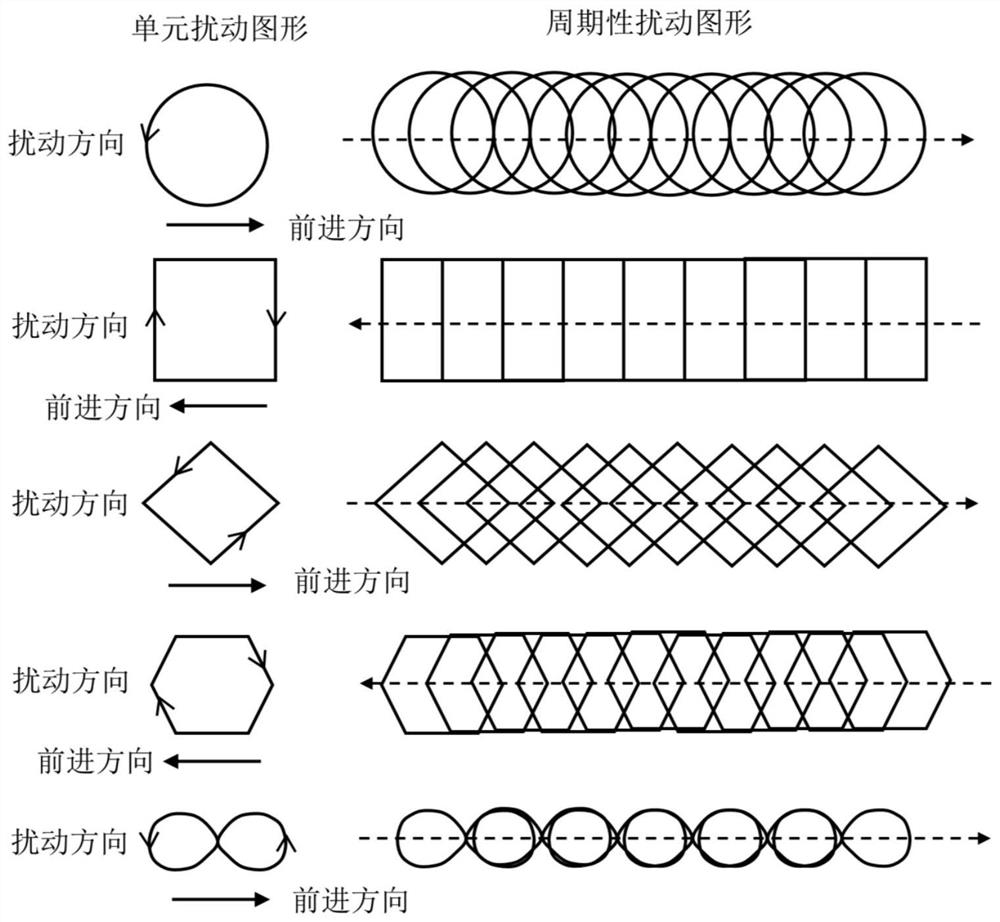

[0139] Step 1: Determine that the laser motion trajectory is a periodic circular disturbance, and set the self-disturbance parameters: the radius of the circle is 1mm, the number of disturbances is 100, the distance between two adjacent circles is the same as 0.1mm, and the disturbance speed is 20mm / s. The disturbance direction is clockwise, then the position coordinates of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com