Production method of large-circulation grid carved raschel blanket

A Raschel blanket, a production method technology, applied in the direction of dyeing method, textile material processing, heating/cooling fabric, etc., can solve the problems of poor fabric pattern texture, insufficient softness and comfort, etc., to achieve realistic texture and abstract feeling Strong and comfortable to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

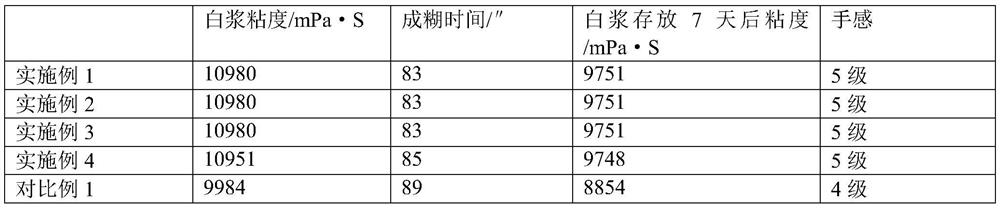

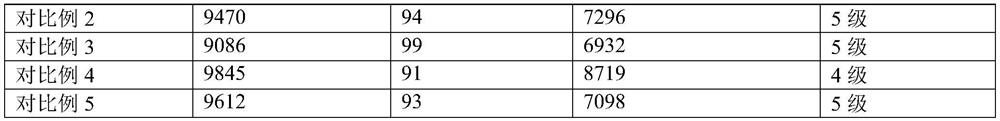

Examples

preparation example Construction

[0039] Wherein, the preparation method of modified thickener comprises the steps:

[0040] (1) Stir and dissolve sodium alginate and hydrogen peroxide in water to obtain sodium alginate solution; then add hydroxypropyl starch and α-amylase at the same time, the mass ratio of sodium alginate, hydrogen peroxide and starch is 20~30:0.3~ 0.5: 10-15, add α-amylase at 400-600u / g starch; then stir and react at 35-46°C for 8-18 hours, then add sodium carbonate and gluconolactone, the amount of sodium carbonate added is the above The weight of the mixed solution is 0.2-1%, the mass ratio of sodium carbonate to gluconolactone is 0.8-1:1, and after stirring and reacting, a sodium alginate / starch composite solution is obtained;

[0041] (2) Adjust the pH of the sodium alginate solution obtained in step (1) to 3.7-4.5, and add formaldehyde, N, N, N-methylenebisacrylamide, acrylic acid, cyclohexyl isonitrile and dipropylene phthalate are stirred, and then the pH is adjusted to 5-6 with amm...

Embodiment 1

[0044] A method for producing a raschel blanket engraved with large circular grids, comprising the following steps:

[0045] (a) Use ultra-bright polyester ultra-fine fiber 167dtex / 228F ultra-fine denier polyester low-stretch yarn and 167dtex / 84F polyester full-drawn super-bright yarn to carry out warp knitting at intervals, use CAD system to control the warp knitting machine, and move in opposite directions The wool yarn bar of the warp knitting machine is cut after obtaining the gray cloth, and the hair height is 10mm;

[0046] (b) Dyeing: the gray cloth is dyed by padding, the padding speed is 16m / min, the left, middle and right pressure of the roll is 4kg, the air pressure in the middle, and the left and right sides are oil pressure; the dyeing liquid includes disperse dyes and thickening agent, disperse dyes include disperse yellow with a concentration of 2.88g / L, disperse red with a concentration of 3.28g / L and disperse blue with a concentration of 3.74g / L, and the thick...

Embodiment 2

[0053] The difference with embodiment 1 is:

[0054] A method for producing a raschel blanket engraved with large circular grids, comprising the following steps:

[0055] (a) Use polyester superfine fiber 167dtex / 228F ultra-fine denier polyester low elastic yarn and 167dtex / 84F polyester full-drawn super bright yarn to carry out warp knitting at intervals, use CAD system to control the warp knitting machine, and move the warp knitting machine in different directions The woolen yarn bar is cut after obtaining the gray cloth, and the wool height is 9.9mm;

[0056] (b) Dyeing: the gray cloth is dyed by padding, the padding speed is 15m / min, the left, middle, and right pressure of the roll is 6kg, the air pressure in the middle, and the left and right sides are oil pressure; the dyeing liquid includes disperse dyes and thickening agent, disperse dyes include disperse yellow with concentration of 3g / L, disperse red with concentration of 3g / L and disperse blue with concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com