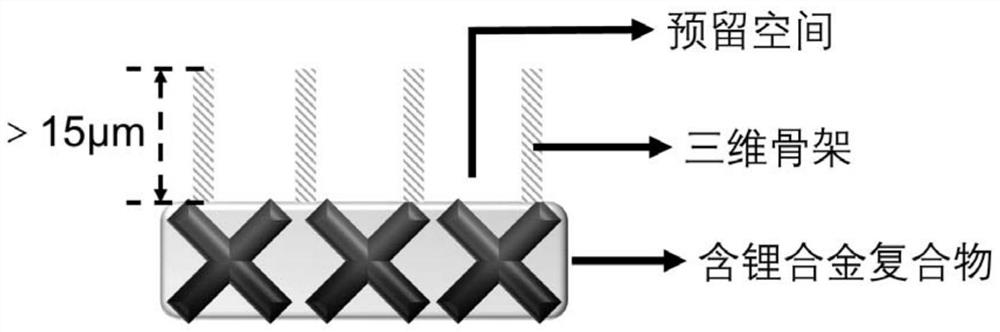

Lithium composite negative electrode material with three-dimensional skeleton structure and reserved space on surface and preparation method of lithium composite negative electrode material

A technology for negative electrode materials and reserved space, applied in the field of lithium composite negative electrode materials and its preparation, to achieve stable structure, inhibit the formation of lithium dendrites, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

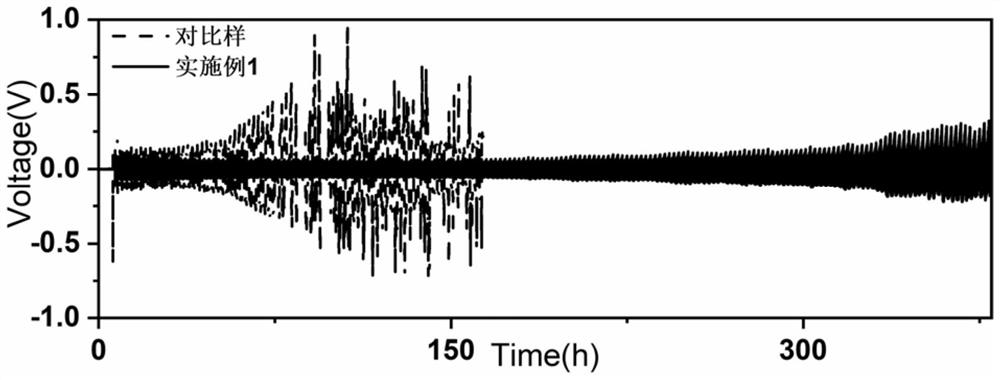

Embodiment 1

[0030] The precursor material zinc fluoride powder (size less than 1mm) is hot-filled with metal lithium to form a lithium-rich lithium-zinc alloy composite electrode material with lithium fluoride particle arrays and reserved spaces on the surface. The specific process is: put lithium metal on stainless steel foil, heat up to 300°C in an argon atmosphere until the lithium metal is completely melted; then add zinc fluoride with a molar ratio of 1:50 to lithium metal into the molten metal Stirring in lithium for 1 hour, mixing molten metal and powder evenly, cooling to room temperature, obtaining a lithium-rich lithium-zinc alloy composite electrode material with lithium fluoride particle arrays and reserved spaces on the surface.

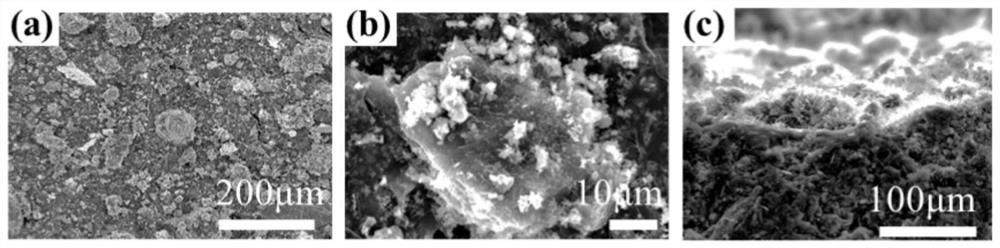

[0031] The scanning electron microscope (SEM) photograph of the lithium composite electrode material that this example makes is as follows figure 2 shown; among them figure 2 a is the SEM photo of the obtained lithium composite electrode material...

Embodiment 2

[0033] The precursor material aluminum fluoride powder (size less than 1mm) is hot-filled with metal lithium to form a lithium-rich lithium-aluminum alloy composite electrode material with a lithium fluoride particle array and reserved space on the surface. The specific process is: put metal lithium on stainless steel foil, heat up to 350°C in an argon atmosphere until the metal lithium is completely melted; then add aluminum fluoride with a molar ratio of 1:100 to metal lithium into the molten metal Stirring in lithium for 0.5 hours, mixing molten metal and powder evenly, cooling to room temperature, obtaining a lithium-rich lithium-aluminum alloy composite electrode material with lithium fluoride particle arrays and reserved spaces on the surface.

Embodiment 3

[0035] The precursor material copper fluoride powder (size less than 1mm) is hot-filled with metal lithium to form a lithium-rich lithium-copper alloy composite electrode material with lithium fluoride particle arrays and reserved spaces on the surface. The specific process is: put lithium metal on stainless steel foil, heat up to 450°C in an argon atmosphere until the lithium metal is completely melted; then add copper fluoride with a molar ratio of 1:200 to lithium metal into the molten metal Stirring in lithium for 2 hours, mixing molten metal and powder evenly, cooling to room temperature, obtaining a lithium-rich lithium-copper alloy composite electrode material with lithium fluoride particle arrays and reserved spaces on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com