Catalyst and preparation method and application thereof, and method for preparing unsaturated carbonate

A catalyst and solvothermal reaction technology, applied in catalyst activation/preparation, catalytic reaction, chemical instruments and methods, etc., can solve problems such as cumbersome processes, and achieve the effects of simple process, less loss and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

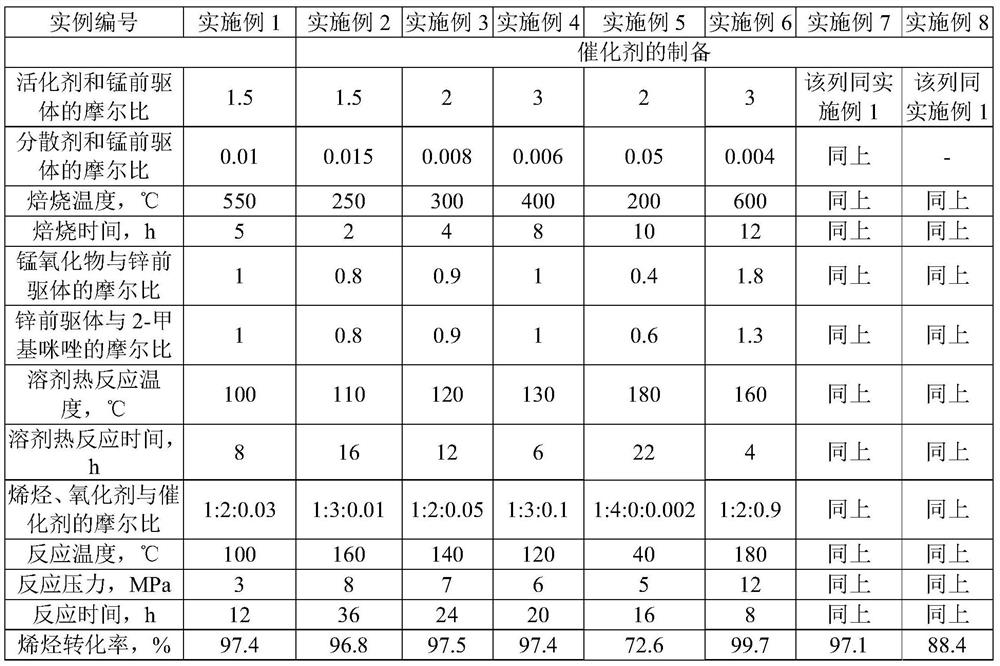

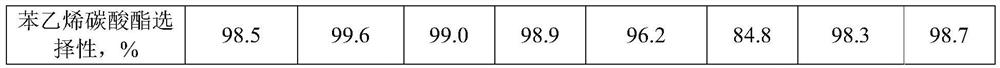

[0024] As previously mentioned, the second aspect of the present invention provides a method for preparing a catalyst, the method comprising the following steps:

[0025] (1) mixing the manganese precursor with the activator and the first solvent, followed by separation, optional washing and optional drying, and then roasting to obtain manganese oxide;

[0026] (2) mixing the manganese oxide with the zinc precursor, 2-methylimidazole and a second solvent for solvothermal reaction, followed by separation, optional washing, and optional drying;

[0027] The molar ratio of the manganese oxide in terms of manganese element to the zinc precursor in terms of zinc element is 0.3-2.

[0028] The present invention has no limitation on the type of the manganese precursor, as long as the manganese oxide can be prepared through the manganese precursor; preferably, the manganese precursor is selected from potassium permanganate, manganese-containing nitrate, chloride at least one of salt ...

Embodiment approach

[0054] According to a preferred embodiment provided by the invention, the preparation method of the catalyst comprises the following steps:

[0055] (1) firstly mix the dispersant and the activator with the first solvent, then mix with the manganese precursor, sequentially separate, optionally wash and optionally dry, and then bake at 200-600°C for 1 -24h, to obtain manganese oxide;

[0056] (2) First mix the manganese oxide with the second solvent, then mix it with the zinc precursor, and finally mix it with 2-methylimidazole, perform solvothermal reaction at 60-200°C for 1-24h, and then separate , optionally washed, optionally dried;

[0057] The molar ratio of the manganese oxide in terms of manganese element to the zinc precursor in terms of zinc element is 0.3-2.

[0058] As mentioned above, the third aspect of the present invention provides a catalyst prepared by the preparation method described in the second aspect. The composition and performance of the catalyst are...

Embodiment 1

[0076] This example is used to illustrate the catalyst of the present invention, its preparation method and its application in the preparation of unsaturated carbonate.

[0077] Catalyst preparation:

[0078] (1) Add 0.182g of hexadecyltrimethylammonium bromide, 8.1g of benzyl alcohol and 500ml of water into the reaction kettle, after stirring, add 7.9g of potassium permanganate, stir, filter, wash with water at 100°C Drying; then roasting at 550°C for 5h in a muffle furnace to obtain manganese oxide.

[0079] (2) Disperse 1 g of the prepared manganese oxide in 50 ml of methanol, add 3.4 g of zinc nitrate and stir, add 0.94 g of 2-methylimidazole, seal after stirring, perform solvothermal reaction at 100 ° C for 8 hours, and then Filter, wash with methanol, and dry at 100° C. to obtain catalyst S1.

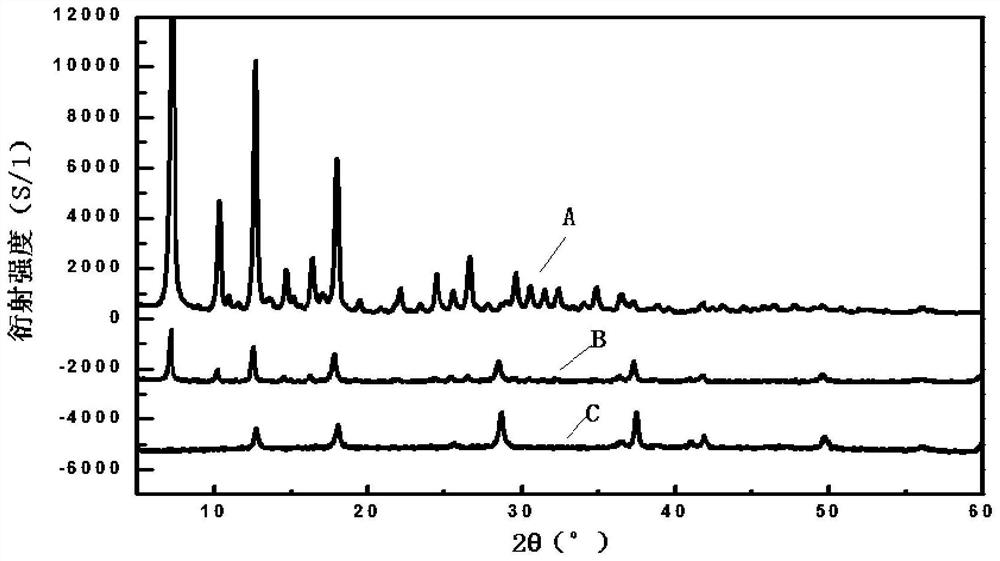

[0080] Carry out XRD characterization to gained catalyst, its characterization result is as follows figure 1 Shown in the B curve. Among them, curve A is the XRD pattern of ZI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com