Strontium barium sodium niobate tungsten bronze type piezoelectric ceramic material with low sintering temperature and anisotropy and preparation method thereof

A technology of strontium barium niobate sodium tungsten bronze and low sintering temperature, which is applied in the field of tungsten bronze structural ceramic materials, can solve the problems of deteriorating sintering behavior, reducing density, and deteriorating performance, so as to reduce energy loss, increase density, and excellent Effects of Dielectric and Ferroelectric Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

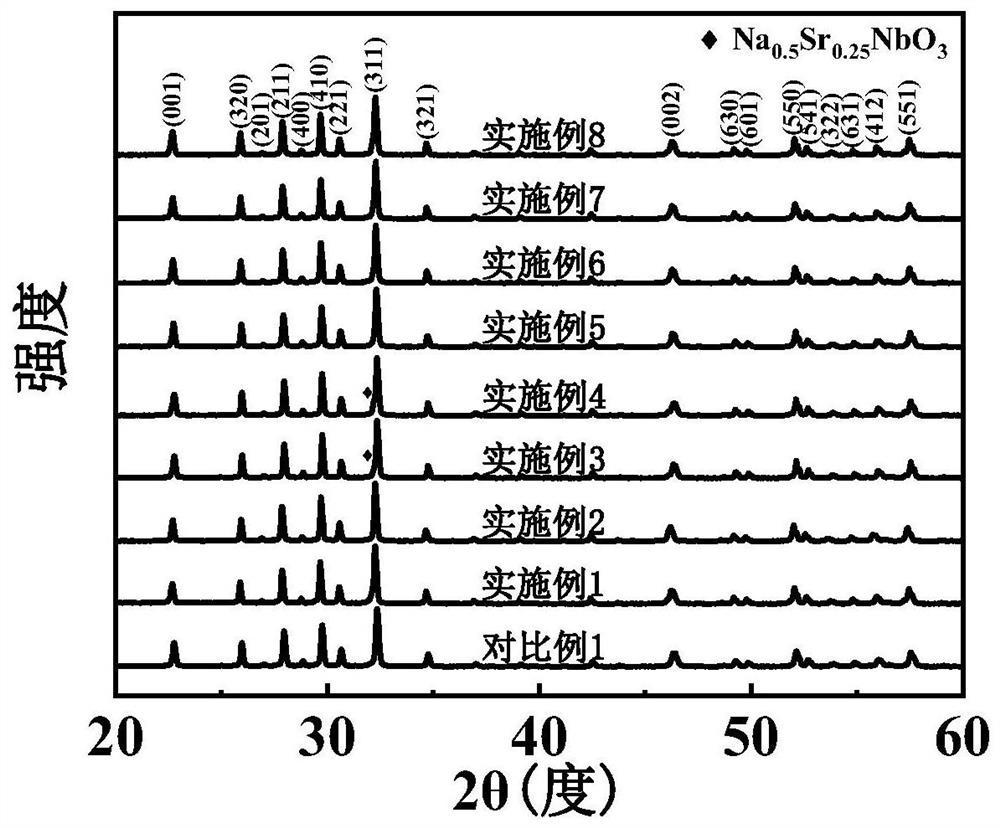

Examples

Embodiment 1

[0033] 1. Ingredients

[0034] According to Sr 1.4 Ba 0.6 NaNb 5 o 15 The stoichiometric ratio, respectively weighed SrCO with a purity of 99.00% 3 5.9873g of BaCO with a purity of 99.00% 3 3. 4300g of Na with a purity of 99.80% 2 CO 3 1.5229g of Nb with a purity of 99.99% 2 o 5 19.0598g, mixed evenly and put into a nylon jar, using zirconium balls as grinding balls and absolute ethanol as ball milling media, using a ball mill with a speed of 401 rpm to fully mix and ball mill for 24 hours, separate the zirconium balls, and dry at 80°C After 24 hours, grind in a mortar for 30 minutes to obtain a raw material mixture.

[0035] 2. Pre-burning

[0036] Put the raw material mixture in an alumina crucible, compact it with an agate rod, cover it, place it in a resistance furnace, raise the temperature to 1230°C at a heating rate of 3°C / min, keep it warm for 6 hours, and cool it down to room temperature naturally with the furnace, then take it out of the furnace , Grind...

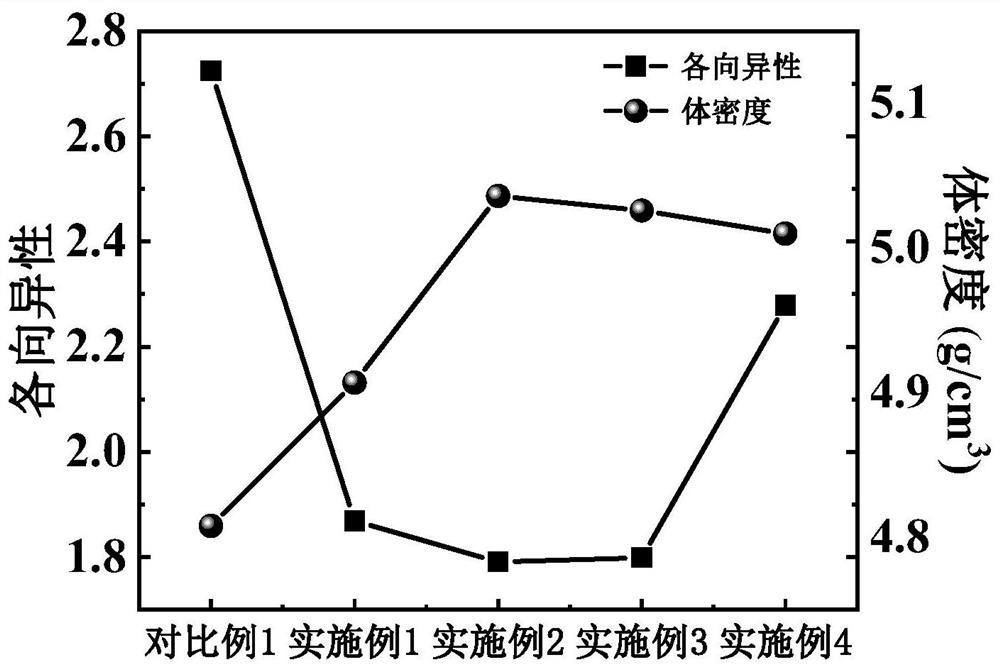

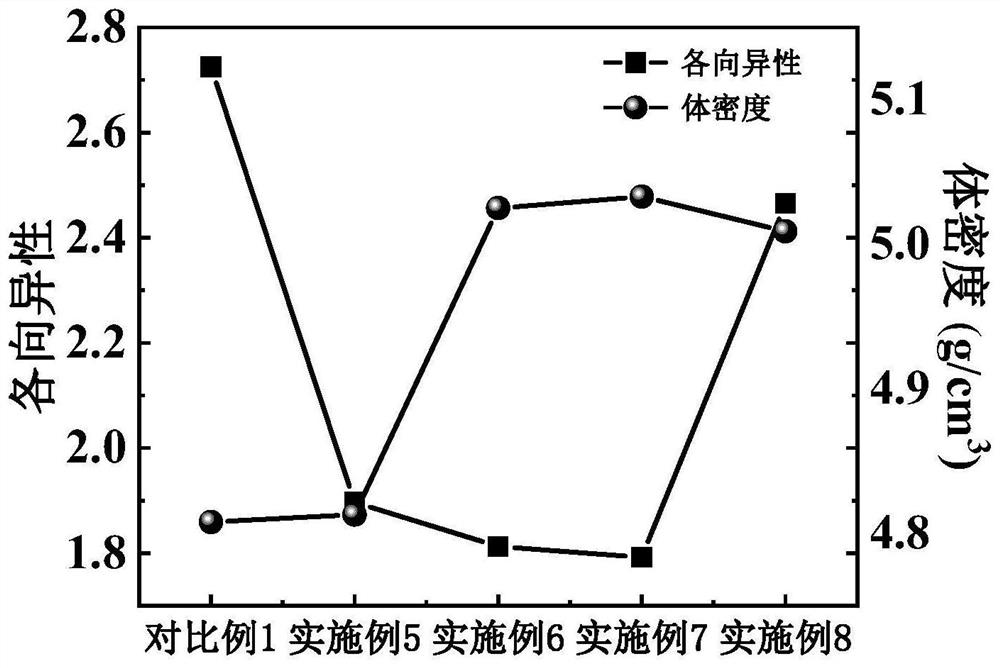

Embodiment 2

[0046] In step 3 of this embodiment, 20 g of calcined powder and 0.1 g of CuO with a purity of 99.99% are packed into a nylon tank, and the other steps are the same as in Example 1 to obtain a structural formula of Sr 1.4 Ba 0.6 NaNb 5 o 15 +0.5wt.% CuO barium strontium niobate sodium tungsten bronze piezoelectric ferroelectric ceramic material.

Embodiment 3

[0048] In step 3 of this embodiment, put 20 g of calcined powder and 0.15 g of CuO with a purity of 99.99% into a nylon tank; Raise the temperature to 1000°C, then raise the temperature to 1230°C at a rate of 3°C / min, keep the temperature for 30 minutes, continue to cool down to 1180°C at a rate of 3°C / min, keep the temperature for 2 hours, and cool down to room temperature naturally with the furnace, other steps are the same as Embodiment 1 is identical, obtains structural formula and is Sr 1.4 Ba 0.6 NaNb 5 o 15 +0.75wt.% CuO strontium barium sodium tungsten bronze type piezoelectric ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com