High-density microporous polyurethane foam and preparation method thereof

A polyurethane, high-density technology, applied in the field of polyurethane foam, can solve the problems of cell wall collapse, shortened service cycle, molecular chain breakage, etc., and achieve the effect of good buffering and excellent resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

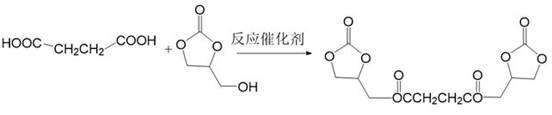

Method used

Image

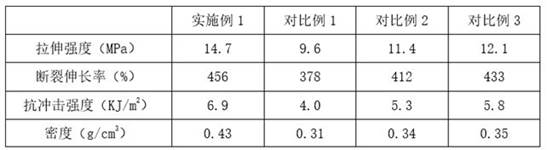

Examples

Embodiment 1

[0045] A kind of high-density microporous polyurethane foam, its preparation method, comprises the following steps:

[0046] Step 1, prepare methylene bisfurfurylamine:

[0047]a. Weigh furfurylamine and mix it with deionized water, put it under the condition of 0~5℃ and stir well, then add hydrochloric acid solution drop by drop and keep stirring, after complete dropwise addition, heat up to 20~28℃ to get the mixed solution A; Wherein, the concentration of hydrochloric acid solution is 4mol / L, and the mass ratio of furfurylamine and deionized water is 1:3, and the mass ratio of hydrochloric acid solution and furfurylamine is 1:0.5;

[0048] b. Add the aqueous solution of formaldehyde to the mixed liquid A drop by drop. After complete dropwise addition, stir and react at 20~28°C for 4~6h. After the reaction, add sodium hydroxide solution until the pH of the reaction solution is 9.5~ 10.5, then add toluene to extract and take the organic layer, wash the organic layer with puri...

Embodiment 2

[0057] A kind of high-density microporous polyurethane foam, its preparation method, comprises the following steps:

[0058] Step 1, prepare methylene bisfurfurylamine:

[0059] a. Weigh furfurylamine and mix it with deionized water, put it under the condition of 0~5℃ and stir well, then add hydrochloric acid solution drop by drop and keep stirring, after complete dropwise addition, heat up to 20~28℃ to get the mixed solution A; Wherein, the concentration of hydrochloric acid solution is 3mol / L, and the mass ratio of furfurylamine and deionized water is 1:2, and the mass ratio of hydrochloric acid solution and furfurylamine is 1:0.3;

[0060] b. Add the aqueous solution of formaldehyde to the mixed liquid A drop by drop. After complete dropwise addition, stir and react at 20~28°C for 4~6h. After the reaction, add sodium hydroxide solution until the pH of the reaction solution is 9.5~ 10.5, then add toluene to extract and take the organic layer, wash the organic layer with pur...

Embodiment 3

[0069] A kind of high-density microporous polyurethane foam, its preparation method, comprises the following steps:

[0070] Step 1, prepare methylene bisfurfurylamine:

[0071] a. Weigh furfurylamine and mix it with deionized water, put it under the condition of 0~5℃ and stir well, then add hydrochloric acid solution drop by drop and keep stirring, after complete dropwise addition, heat up to 20~28℃ to get the mixed solution A; Wherein, the concentration of hydrochloric acid solution is 5mol / L, and the mass ratio of furfurylamine and deionized water is 1:4, and the mass ratio of hydrochloric acid solution and furfurylamine is 1:0.6;

[0072] b. Add the aqueous solution of formaldehyde to the mixed liquid A drop by drop. After complete dropwise addition, stir and react at 20~28°C for 4~6h. After the reaction, add sodium hydroxide solution until the pH of the reaction solution is 9.5~ 10.5, then add toluene to extract and take the organic layer, wash the organic layer with pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com