Synthesis method for stably improving impact strength of polyethersulfone

A technology of impact strength and synthesis method, which is applied in the field of polyethersulfone, can solve the problem of no increase in the mechanical strength of polysulfone compounds, and achieve the effects of improved impact strength performance, improved shrinkage, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

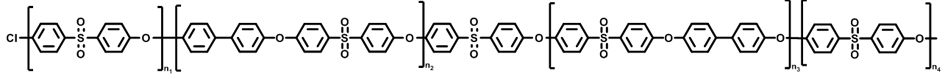

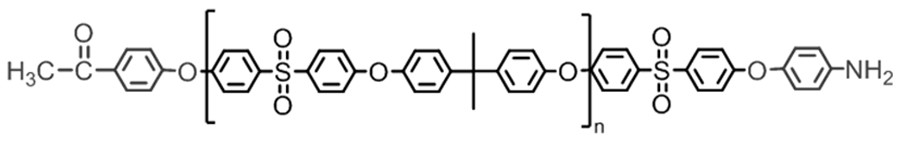

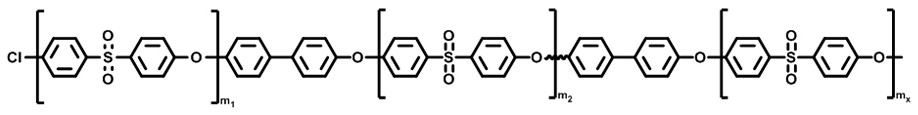

Method used

Image

Examples

Embodiment 1

[0034] Synthetic polyethersulfone by synthetic method of the present invention, method is as follows:

[0035] With condensing, N 2 118.88g (0.475mol) 4,4'-sulfonyldiphenol, 145.02g (0.505mol) 4,4'-dichlorodiphenyl Sulfone, 69.80g (0.505mol) K 2 CO 3 1. Add 272ml of N-methylpyrrolidone, gradually increase the temperature from room temperature to 190°C, add 146ml of N-methylpyrrolidone during the reaction, and extract the effluent at a rate of 70ml / h at 190°C for 3h during the reaction ( The water content in the production liquid is less than 0.3%), the temperature is maintained at 190°C for 6 hours, and then 50ml of N-methylpyrrolidone solution with a concentration of 0.5mol / L 4,4'-biphenol is added (after 2 hours, the Add 50% 4,4'-biphenol solution dropwise at a constant speed within 0.5h, add 40% 4,4'-biphenol solution dropwise at a constant speed within 1h, and add 10% 4,4'-biphenol solution), and react for 1 hour after the addition is completed. Add 500ml of N-methylp...

Embodiment 2

[0037] Synthetic polyethersulfone by synthetic method of the present invention, method is as follows:

[0038] With condensing, N 2 112.62g (0.45mol) 4,4'-sulfonyl diphenol, 150.76g (0.525mol) 4,4'-dichlorodiphenyl Sulfone, 59.35g (0.56mol) Na 2 CO 3 , Add 224ml of N,N-dimethylacetamide, gradually increase the temperature from room temperature to 160°C, add 146 ml of N,N-dimethylacetamide during the reaction, and add 70 ml / The effluent was produced at a speed of h for 3 hours (the water content in the produced solution was less than 0.3%), and the temperature was kept at 160°C for 8 hours, and then N,N-dimethyl with a concentration of 1mol / L 4,4'-biphenol was added 50ml of solution in acetamide (after adding 2h, add 50% 4,4'-biphenol solution dropwise at a constant speed within 0.5h, and add 40% 4,4'-biphenol solution dropwise at a constant speed within 1h Solution, add 10% 4,4'-diphenol solution dropwise at a constant speed within 0.5h), and react for 1h after the additi...

Embodiment 3

[0040] Synthetic polyethersulfone by synthetic method of the present invention, method is as follows:

[0041] With condensing, N 2 100.11g (0.4mol) 4,4'-sulfonyldiphenol, 172.30g (0.6mol) 4,4'-dichlorodiphenyl Sulfone, 60.00g (0.6mol) KHCO 3 1. Add 190ml of sulfolane, gradually increase the temperature from room temperature to 200°C, add 146 ml of sulfolane during the reaction, extract the effluent at 200°C at a rate of 70 ml / h for 3 hours (the water content in the produced liquid is low 0.3%), the temperature was maintained at 200°C for 5 hours, and then 50ml of a solution in sulfolane with a concentration of 2mol / L 4,4'-biphenol was added (after 2.5 hours, 50% of 4,4 '-biphenol solution, add 40% 4,4'-biphenol solution dropwise at a constant speed within 1h, and add 10% 4,4'-biphenol solution dropwise at a constant speed within 0.5h), After the addition was completed, the reaction was carried out for 1 h. Add 700ml of sulfolane to dilute the reaction polymerization solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com