Cut flower fresh-keeping treatment system and method

A processing system and processing method technology, applied in the field of cut flower fresh-keeping processing system, can solve the problems of cold storage imbalance, difference, affecting the pre-cooling effect of cut flowers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] This embodiment provides a fresh-keeping treatment method for cut flowers, including: (1) unloading; (2) pretreatment with pretreatment liquid; (3) intelligent grading; (4) packaging; (5) boxing; (6) differential pressure Pre-cooling; (7) storage of cut flowers; (8) quality inspection; (9) packing of refrigerant for shipment and other nine steps. Grading is carried out by automatic cutting flower automatic grading equipment. Pre-cooling is carried out in a differential pressure pre-cooling room, and the final temperature is 4~6°C. Storage is carried out in a low-temperature storage room at a temperature of 2-4°C. The detailed processing steps are as follows:

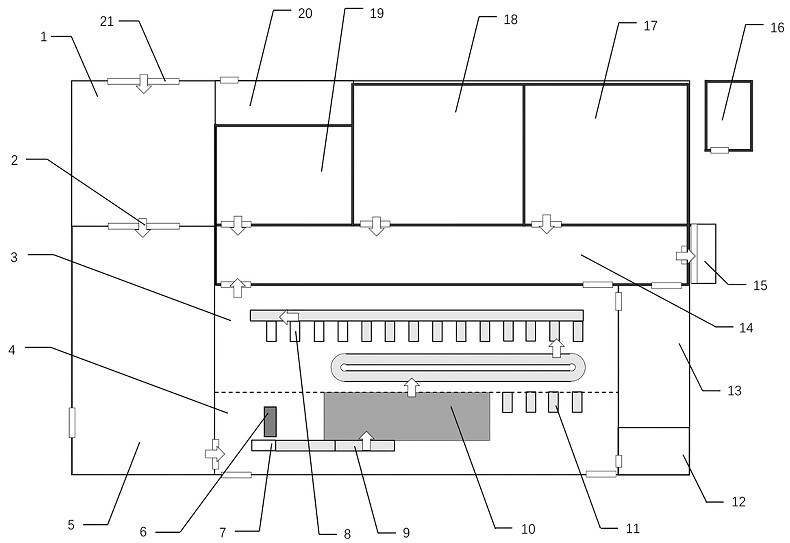

[0049] (1) Flower unloading: Clean the unloading area 1 thoroughly before unloading flowers, and then use disinfectant water or ultraviolet lamps for disinfection and sterilization, and set the area temperature to 20°C through the central air conditioner; after the cut flowers are transported with water to the p...

Embodiment 3

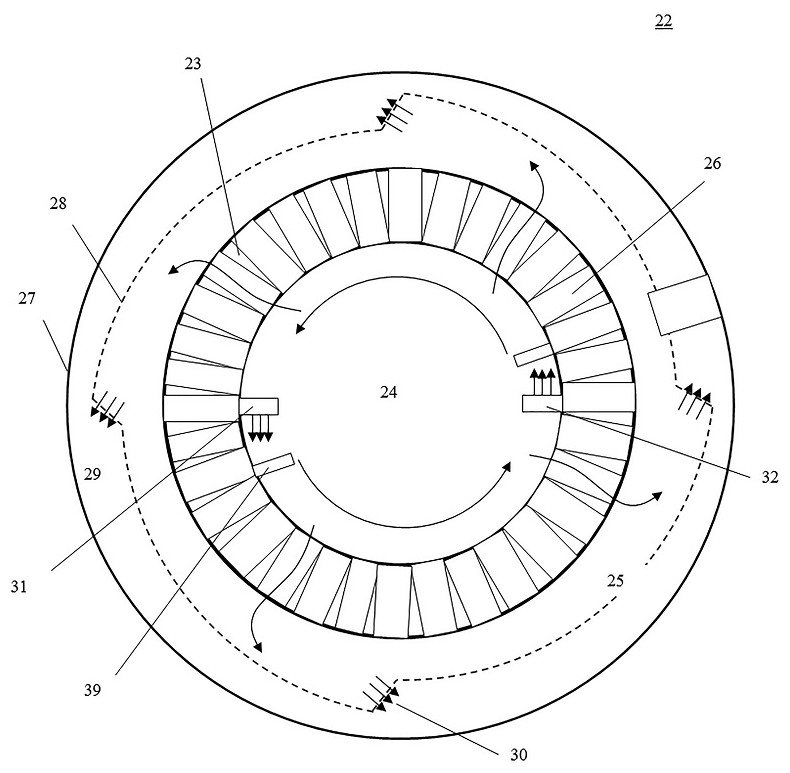

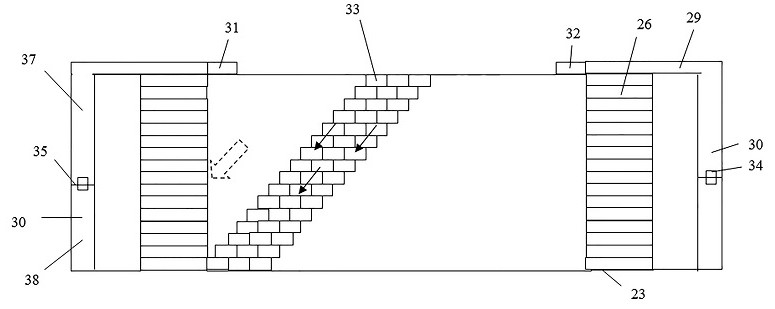

[0059] This embodiment discloses a differential pressure pre-cooler, which at least includes a store body 22 . Such as figure 2 As shown, the storage body 22 is set as a cylindrical storage body. The storage body 22 at least includes a ground, a surrounding wall and a top surface. Preferably, the top surface of the storage body 22 is sequentially arranged as a surface layer, a moisture barrier layer, a roof and an insulation layer from bottom to top; layer composition. Preferably, the insulation layers of the top surface of the storage body 22 and surrounding walls are all made of thermal insulation panels. The ground of the storage body 22 is composed of a temperature uniform layer, a moisture barrier layer and an insulation layer from bottom to top. Preferably, the thermal insulation layer of the ground of the storage body 22 adopts double-layer extruded polystyrene boards. Preferably, the storage body 22 further includes a third enclosure wall 23 disposed inside the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com