Method for high-pressure homogeneous anaerobic digestion of high-solid-content sludge

A high-pressure homogenization and anaerobic digestion technology is applied in the environmental field to achieve the effects of low economic cost, remarkable effect and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

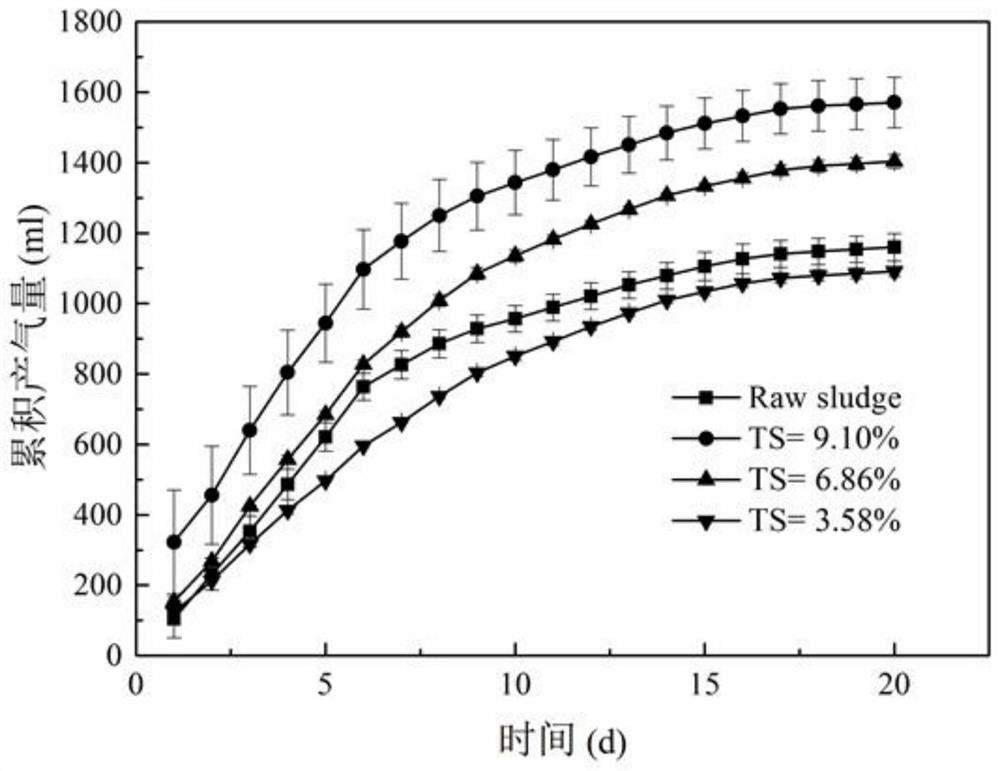

[0046] (1) Get a certain amount of sludge with a solid content rate of 17.10%, dilute it into sludge with a solid content rate of 9.10%, and use a 50 colloid mill to pulverize large-size impurities in the sludge;

[0047] (2) Take 500mL of the sludge prepared in step (1), pour it into the hopper of the high-pressure homogenizer, adjust the pressure gauge to 50MPa, stir the sludge in the hopper, and obtain the high-pressure homogenized sludge through the discharge port, homogenize once , its SCOD reached 5169.5mg / L;

[0048] (3) Put 150g of sludge into a 500ml normal saline bottle, then add 300g of inoculum, pass in nitrogen gas for 1min, seal it, and collect the gas produced by drainage and gas collection. The temperature was controlled at 38°C, and after 21 days of anaerobic fermentation, the gas production reached 1991ml, and the sludge VS removal rate reached 38.90%.

Embodiment 2

[0050] (1) Get a certain amount of sludge with a solid content rate of 17.10%, dilute it into sludge with a solid content rate of 7.10%, and pulverize large-size impurities in the sludge with a 50 colloid mill;

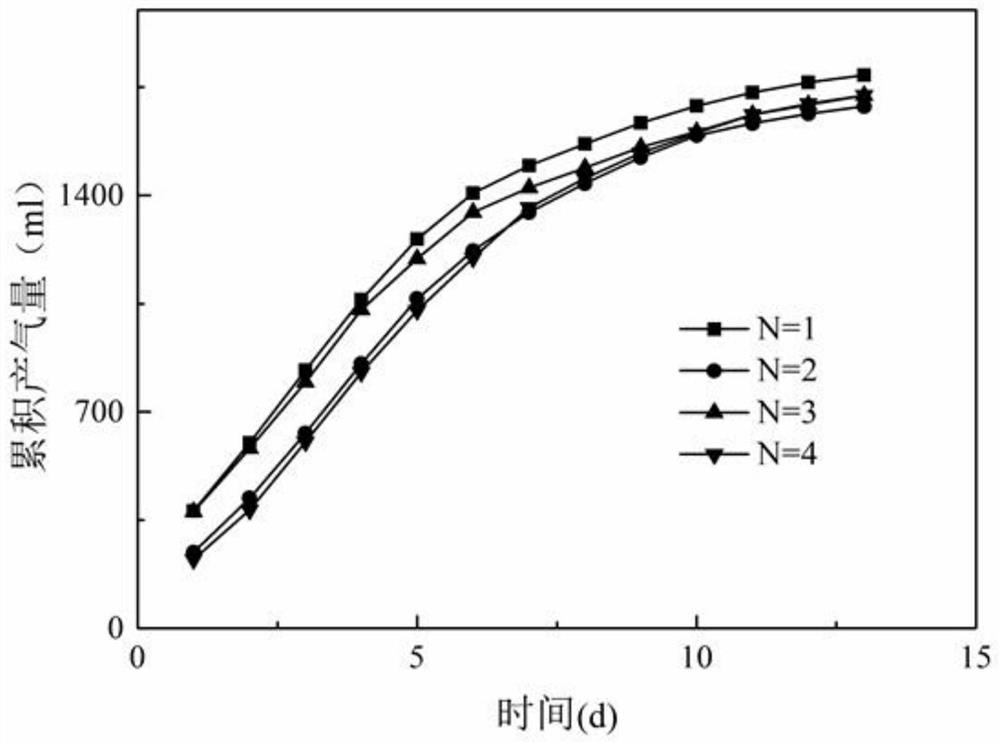

[0051] (2) Take 500mL of the sludge prepared in step (1), pour it into the hopper of the high-pressure homogenizer, adjust the pressure gauge to 20MPa, stir the sludge in the hopper, obtain the high-pressure homogenized sludge through the discharge port, and repeat the homogenization for 4 Second, its SCOD reached 10950mg / L;

[0052] (3) Put 150g of sludge into a 500mL normal saline bottle, then add 300g of inoculum, pass in nitrogen gas for 1min, seal it, and collect the gas produced by drainage and gas collection. The temperature was controlled at 38°C, and after 21 days of anaerobic fermentation, the gas production reached 1724ml, and the sludge VS removal rate reached 45.73%.

Embodiment 3

[0054] (1) Take a certain amount of sludge with a solid content rate of 4%, concentrate it to a solid content rate of 6.85%, and use a 50 colloid mill to pulverize large-size impurities in the sludge;

[0055] (2) Take 500ml of sludge prepared in step (1), pour it into the high-pressure homogenizer hopper, adjust the pressure gauge to 40MPa, stir the sludge in the hopper, obtain high-pressure homogeneous sludge through the discharge port, and repeat homogenization for 3 Second, its SCOD reached 4003.5mg / L;

[0056] (3) Put 150g of sludge into a 500ml normal saline bottle, then add 300g of inoculum, pass in nitrogen gas for 1min, seal it, and collect the gas produced by drainage and gas collection. The temperature was controlled at 38°C, and after 21 days of anaerobic fermentation, the gas production reached 1304ml, and the sludge VS removal rate reached 38.43%.

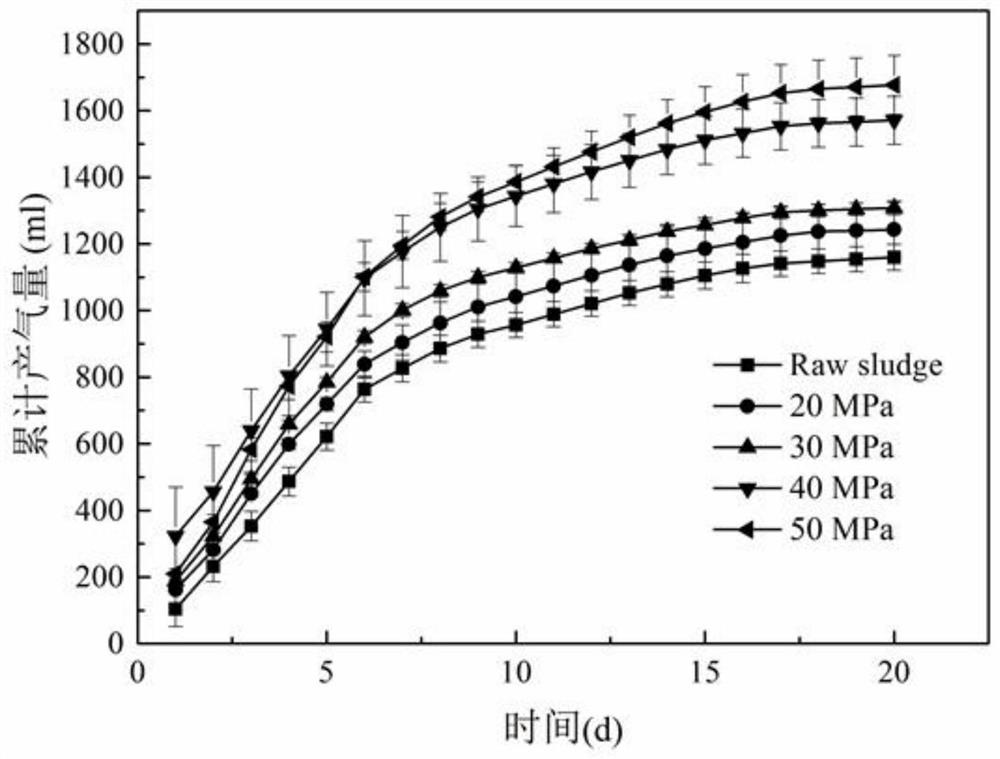

[0057] Such as figure 1 As shown, the high-pressure homogenizer is used to crack the high-solid sludge under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com