Preparation method of Si-Zr-O-C-based ceramic fiber material, product and application

A ceramic fiber and product technology, applied in the field of ceramic fiber material preparation technology, can solve the problems of heat insulation performance and mechanical performance reduction, and achieve the effects of reducing thermal conductivity, enhancing infrared shielding effect, and increasing barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

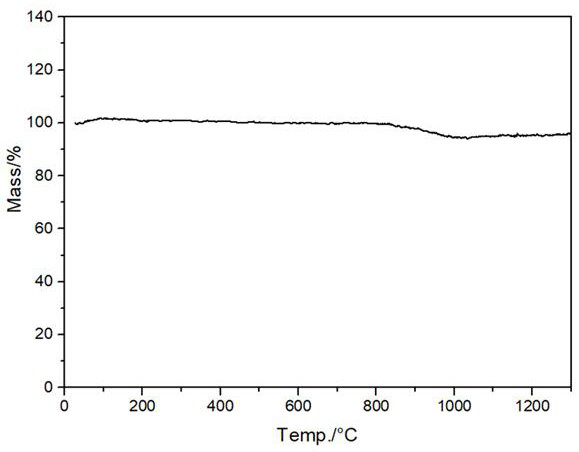

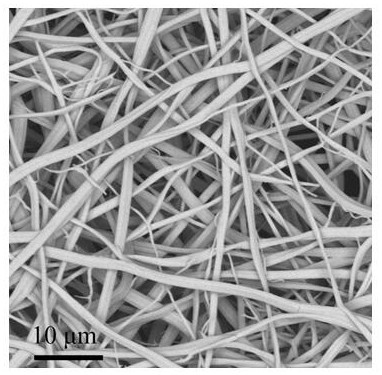

[0039] see figure 1 and figure 2 , a preparation method of Si-Zr-O-C based ceramic fiber material, comprising the following steps:

[0040] Preparation of precursor sol spinning solution: first dissolve the zirconium source in a complexing agent to obtain a primary solution, then mix the primary solution, silicon source, and spinning aid solution to obtain a precursor sol spinning solution; Said spinning aid solution is made of auxiliary solute, auxiliary solvent, catalyst, and said auxiliary solute is any one of the following or mixed arbitrarily: polyvinylpyrrolidone, polyvinyl alcohol, polyvinyl butyral, polyethylene diacetal Alcohol, polyoxyalkylene alcohol;

[0041] Preparation of precursor gel fibers: electrospinning the above precursor sol spinning solution to obtain precursor gel fibers;

[0042]Obtaining the ceramic fiber material: drying and sintering the above-mentioned precursor gel fiber in order to obtain the ceramic fiber material.

[0043] In the preparati...

Embodiment 1

[0070] Preparation of precursor sol spinning solution: Weigh 1.91g of butyl zirconate and dissolve it in 0.6g of acetic acid solution, stir continuously to form a uniform solution, and obtain a primary solution; place 0.25g of PVP in a beaker, add 4.75g of absolute ethanol and 0.5g of 1mol / L dilute nitric acid, magnetic stirring for 1 hour, and ultrasonication for 10 minutes to make the PVP fully dispersed evenly, to obtain a spinning aid solution; add the primary solution and 0.74g VTMS to the spinning In the auxiliary agent solution, stir at room temperature for 30 minutes, so that the zirconium source and the silicon source are fully hydrolyzed and polycondensed to form a precursor sol spinning solution;

[0071] Preparation of precursor gel fiber: put the prepared precursor sol spinning solution into a medical syringe, use electrospinning technology, the voltage is 20kV, the injection rate is 1.5mL / hr, the receiving distance is 15cm, and the spinning The ambient temperatur...

Embodiment 2

[0074] Preparation of precursor sol spinning solution: Weigh 1.91g of butyl zirconate and dissolve it in 0.6g of acetic acid solution, stir continuously to form a uniform solution, and obtain a primary solution; place 0.25g of PVP in a beaker, add 4.75g of absolute ethanol and 0.5g of 1mol / L dilute nitric acid, magnetic stirring for 1 hour, and ultrasonication for 10 minutes to make the PVP fully dispersed evenly, to obtain a spinning aid solution; add the primary solution and 1.48g VTMS to the spinning In the auxiliary agent solution, stir at room temperature for 30 minutes, so that the zirconium source and the silicon source are fully hydrolyzed and polycondensed to form a precursor sol spinning solution;

[0075] Preparation of precursor gel fiber: The prepared precursor sol spinning solution was filled into a medical syringe, and the electrospinning technology was used with a voltage of 20 kV, an injection rate of 1.5 mL / hr, and a receiving distance of 15 cm. The temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com