Preparation method capable of reducing melt index of carbon dioxide-based polyester-polycarbonate copolymer

A technology of carbon dioxide and polycarbonate, which is applied in the field of polymer copolymerization, can solve problems such as gelation, and achieve the effects of improving thermal performance, economical and efficient metal residues, and reducing melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

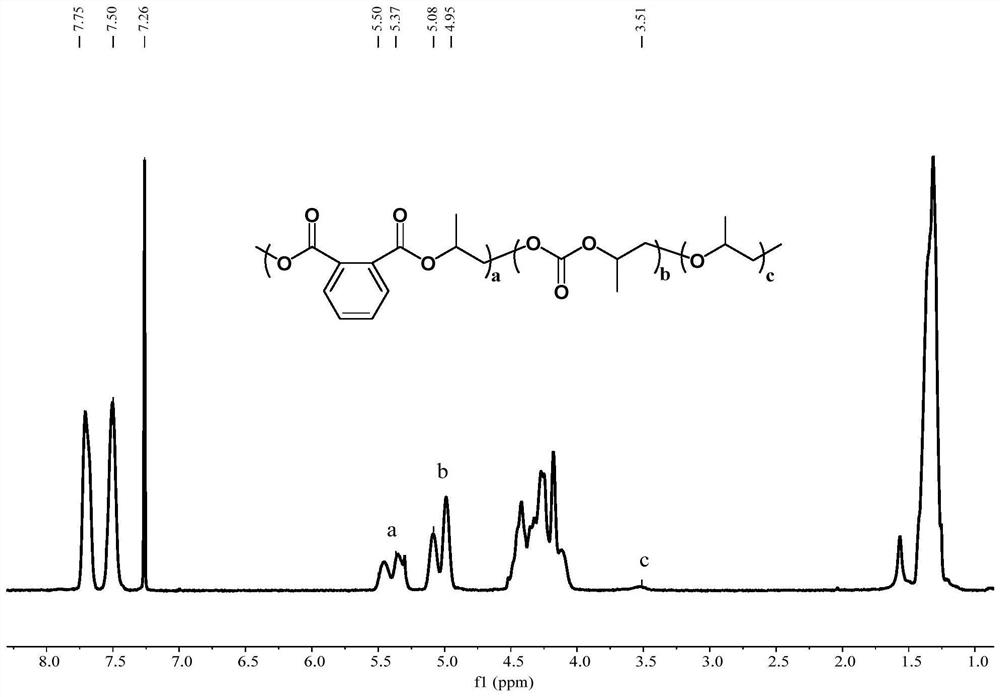

Embodiment 1

[0023] With a 50 mL autoclave as the reaction vessel, 4 g of phthalic anhydride, 12.55 g of propylene oxide, 15 mg of tetraethylammonium chloride, 67.6 mg of diphenylmethane di Isocyanate, 170 μL tripropyl boron solution, added to the autoclave in sequence, then filled with 1.0 MPa high-purity carbon dioxide, reacted in an oil bath at 80 °C for 6 h, released the residual carbon dioxide after the reaction, and diluted the product with dichloromethane , and the catalyst was quenched with dilute hydrochloric acid / ethanol solution, the polymer was precipitated in ethanol, and dried in a vacuum oven. After drying, carry out molecular weight test, nuclear magnetic analysis and thermal property test. M n =135 kDa, PDI = 2.80, 40% polyester, 57% polycarbonate, 3% polyether, T g = 48.7 °C, and the melt index measured at 170 °C under a load of 2.16 kg was 7.3 g / 10 min.

Embodiment 2

[0025] With a 50 mL autoclave as the reaction vessel, 4 g of phthalic anhydride, 12.55 g of propylene oxide, 15 mg of tetraethylammonium chloride, and 135.2 mg of diphenylmethane di Isocyanate and 170 μL tripropyl boron solution were added to the autoclave in sequence, and then filled with 1.0 MPa high-purity carbon dioxide, and reacted in an oil bath at 80 °C for 6 h. After the reaction, the residual carbon dioxide was released, and the product was diluted with dichloromethane , and the catalyst was quenched with dilute hydrochloric acid / ethanol solution, the polymer was precipitated in ethanol, and dried in a vacuum oven. After drying, carry out molecular weight test, nuclear magnetic analysis and thermal property test. M n =154 kDa, PDI = 5.83, polyester content 41%, polycarbonate content 56%, polyether content 3%, T g = 50.0 °C, the melt index measured at 170 °C under a load of 2.16 kg is 6.5 g / 10 min.

Embodiment 3

[0027] With a 50 mL autoclave as the reaction vessel, 4 g of phthalic anhydride, 12.55 g of propylene oxide, 15 mg of tetraethylammonium chloride, and 135.2 mg of diphenylmethane di Add isocyanate and 170 μL tripropyl boron solution into the autoclave in sequence, then fill it with 3 MPa high-purity carbon dioxide, and react in an oil bath at 80 °C for 6 h, release the residual carbon dioxide after the reaction, and dilute the product with dichloromethane , and the catalyst was quenched with dilute hydrochloric acid / ethanol solution, the polymer was precipitated in ethanol, and dried in a vacuum oven. After drying, carry out molecular weight test, nuclear magnetic analysis and thermal property test. M n =210 kDa, PDI = 6.81, polyester content 36%, polycarbonate content 63%, polyether content 1%, T g =52.0 °C, the melt index measured at 170 °C under a load of 2.16 kg is 5.6 g / 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com