Benzoxazine resin-based composition for packaging third-generation semiconductor device and preparation method thereof

A benzoxazine and device packaging technology, applied in the field of electronic packaging materials, can solve problems such as being less than ideal, and achieve the effects of low water absorption, shielding penetration, and low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

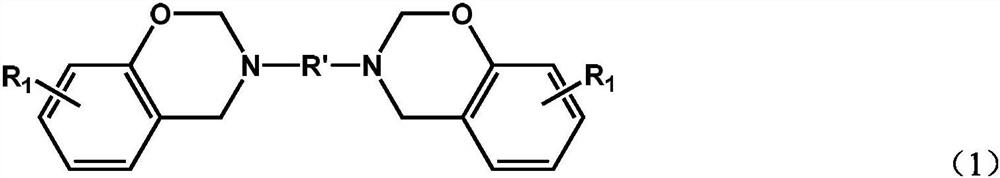

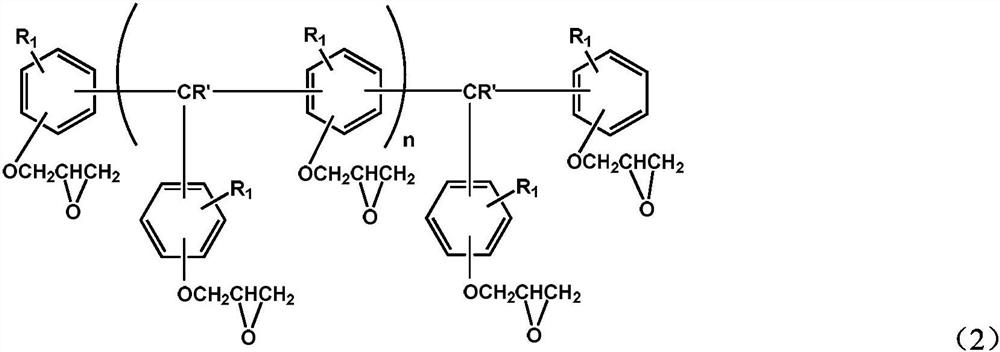

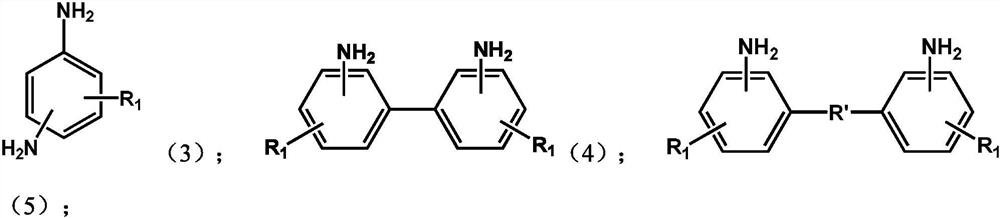

Method used

Image

Examples

Embodiment 1~3

[0063] The raw materials used in Examples 1 to 3 of the present invention and consumption are as shown in Table 1 below:

[0064] Table 1

[0065]

[0066]

[0067] In table 1, the preparation method of epoxy-terminated hyperbranched polysiloxane (EP-HBPSi) is:

[0068] EG (53.78 g, 0.3275 mol) was dissolved in 50 mL of anhydrous toluene, and then Karstedt catalyst (9 μL) was added, and then added into a three-necked flask with a condensing reflux device, and nitrogen was introduced to remove the air. TMDS (20g, 0.1488mol) was dissolved in 50mL of anhydrous toluene, and added to the constant pressure dropping funnel; the temperature of the three-necked flask was raised to 75°C, and nitrogen was blown, and the TMDS solution was added dropwise to the three-necked flask, and the drop was completed in 0.5h (10s / d). Then the temperature was raised to 85°C to continue the reaction for 10 h to obtain the crude product, a transparent yellowish liquid; finally, the excess TMDS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com