Quenching equipment for chain hinge pin with high static load bending strength

A technology of bending strength and quenching equipment, applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problems of easy quenching but not hardening, difficult to grasp the timing of double-liquid conversion, easy quenching cracking, etc., to reduce internal stress, The effect of optimizing the structural performance and increasing the speed of disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

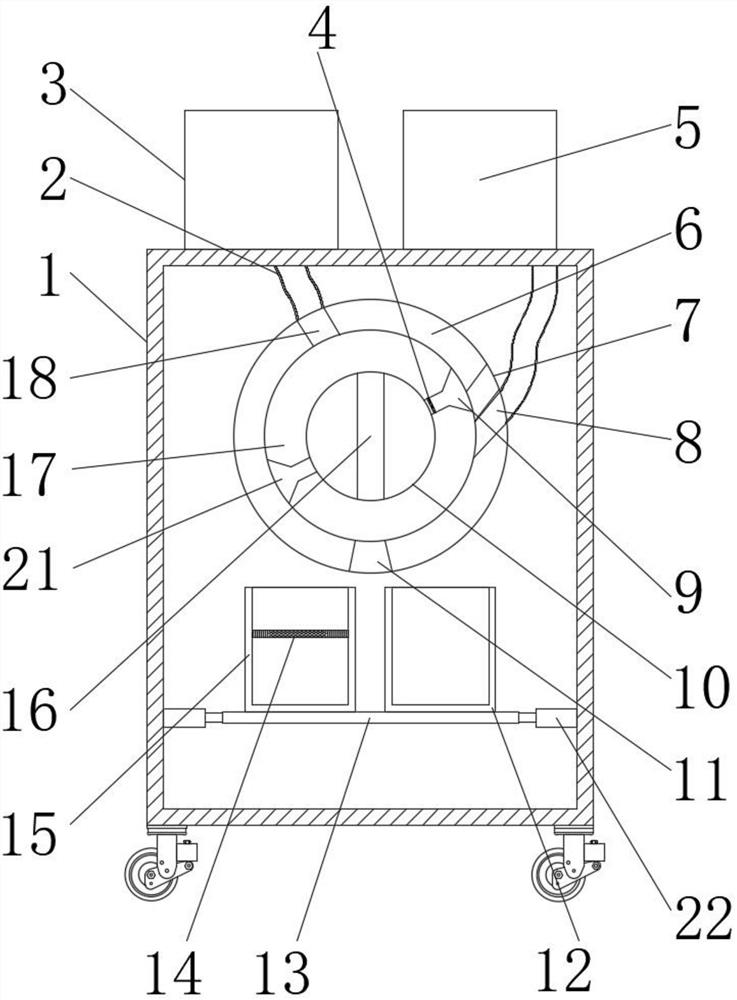

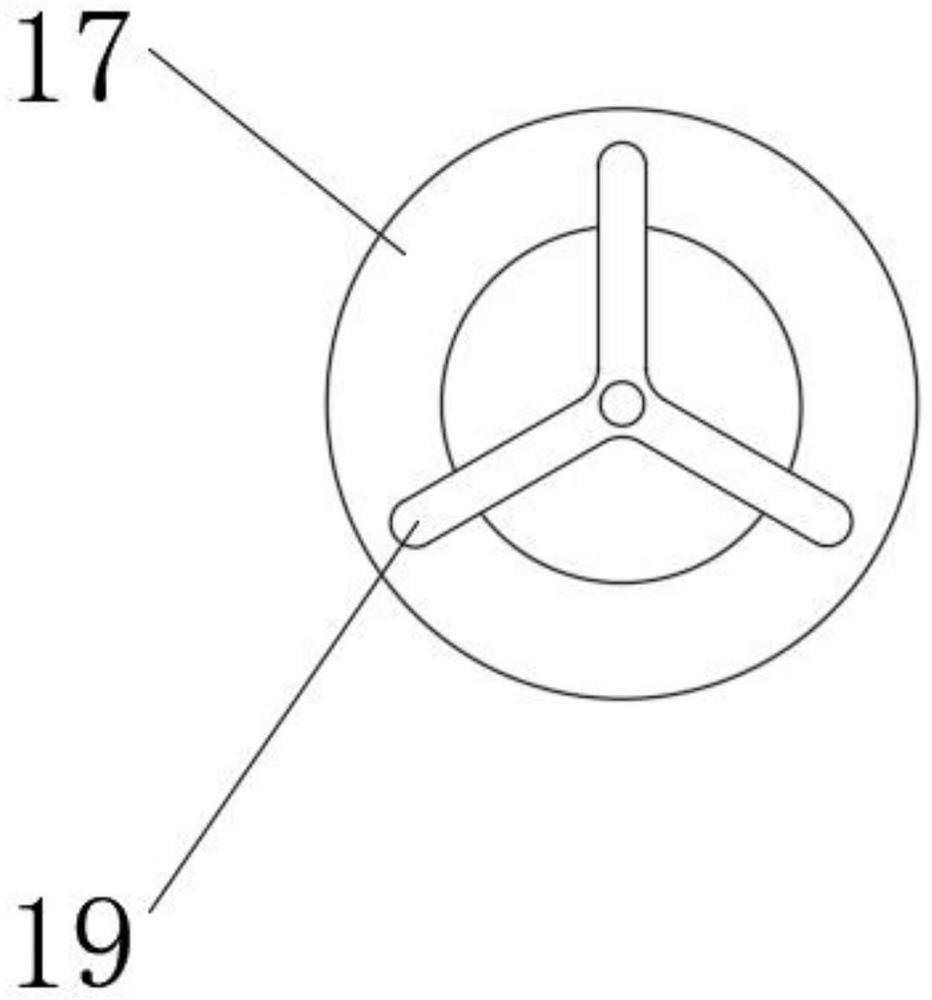

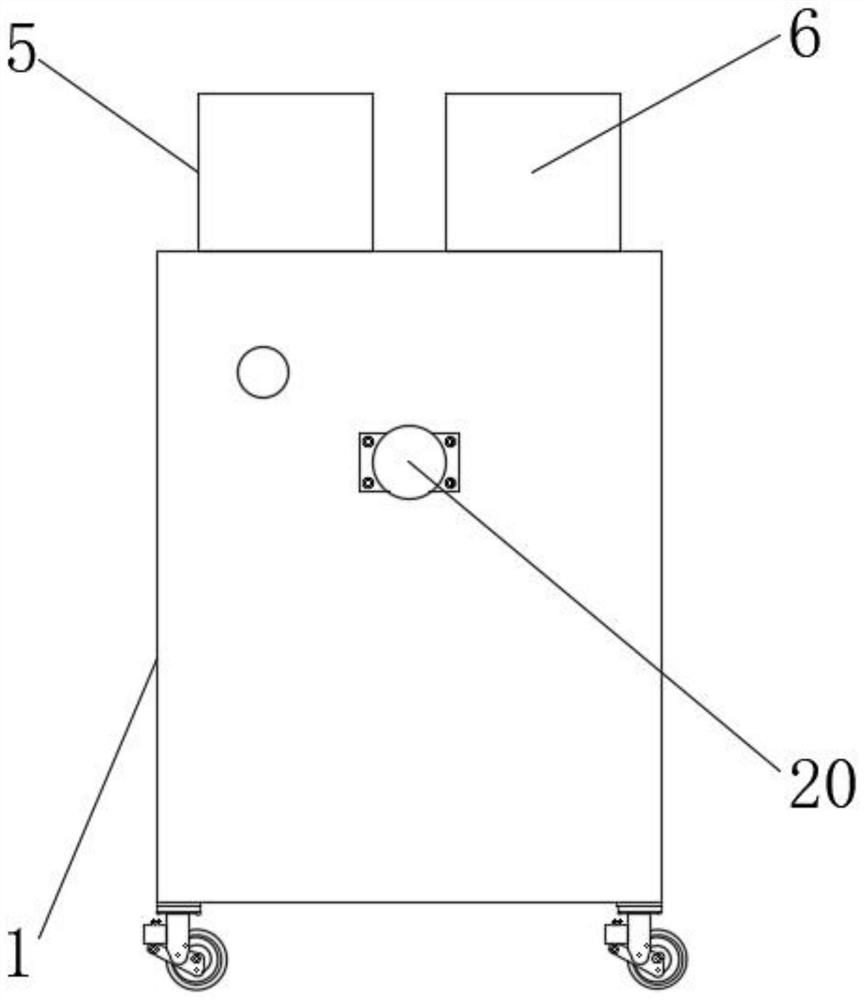

[0024] Such as Figure 1-3 As shown, the embodiment of the present invention provides a quenching device for chain pins with high static load bending strength, including a processing box body 1, a connecting pipe 2, an oil storage tank 3, a water storage tank 5 and a servo motor 20, and the processing box body 1 The inside of the fixed disk 10 is provided with a fixed disk 10, and the inside of the fixed disk 10 is provided with a communication opening 16. The shape of the communication opening 16 is a vertical inline shape, and the communication opening 16 runs through the fixed disk 10. The inside of the processing box body 1 is provided with an adjustment disk 17 , the shape of the adjusting disc 17 is circular, the adjusting disc 17 is rotatably set on the outer surface of the fixed disc 10, the inside of the adjusting disc 17 is provided with a treatment tank 9 and the water opening 21, and the outer surface of the adjusting disc 17 is rotatably sleeved with Fixed limit f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com