High-performance graphene composite silver paste and preparation method thereof

A graphene composite and high-performance technology, applied in the field of solar cell materials, can solve the problems of unstable performance, complex process, and reduce the high conductivity of graphene, and achieve the effect of stable performance and good flexibility of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

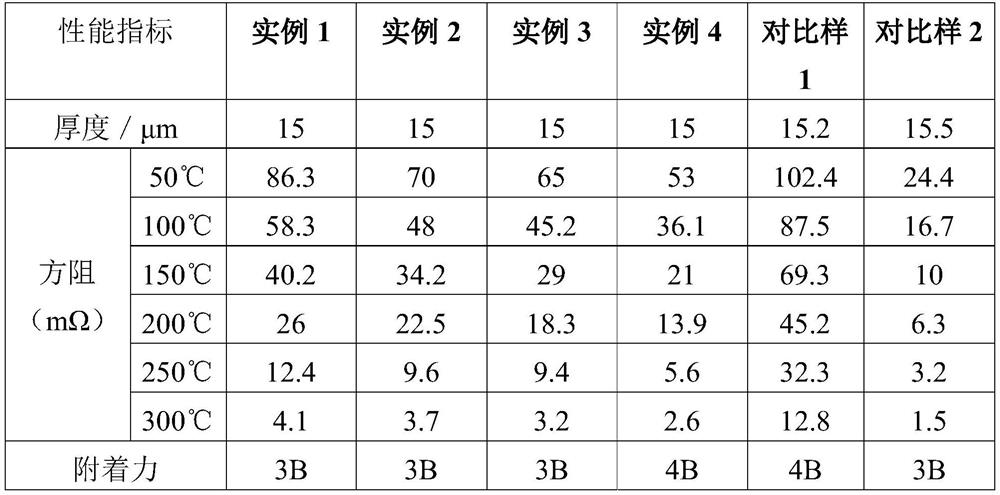

Examples

preparation example Construction

[0024] The embodiment of the present invention provides a kind of preparation method of high-performance graphene composite silver paste, mainly comprises the following steps:

[0025] S1. Weigh graphite powder, nano-silver paste, glass powder, dendritic organic molecules and organic solvent in sequence according to the proportion; among them, graphite powder 5%-20%, nano-silver paste 50-65%, glass powder 3-5%, 0.5% to 2% of dendritic organic molecules, 8% to 41.5% of organic solvents; graphene and nano-glass powder are induced and driven by functional groups of dendritic organic molecules to form zero-dimensional silver nanoparticles uniformly distributed in the A composite system of point-surface bonding on the surface of two-dimensional graphene nanosheets;

[0026] S2. Mix dendritic organic molecules and graphite powder in an organic solvent, stir evenly, and then add mechanical high-speed stripping equipment, continuously high-density shearing and peeling for 6 hours unde...

Embodiment 1

[0031] A high-performance graphene composite silver paste is composed of the following raw materials in terms of mass percentage: 20% of graphite powder, 65% of nano-silver paste, 5% of glass powder, 2% of dendritic organic molecules, and 8% of organic solvent.

[0032] Wherein: the dendritic organic molecule is polyamide-amine.

[0033] The glass powder is silica.

[0034] The organic solvent is a mixture of ethylene glycol: glycerin in a mass ratio of 1:1.

[0035] A preparation method for high-performance graphene composite silver paste, comprising the following steps:

[0036] (1) Weigh graphite powder, nano-silver paste, silicon dioxide, polyamide-amine and organic solvent in sequence according to the above ratio;

[0037] (2) Mix polyamide-amine and graphite powder in an organic solvent, stir evenly, and then add mechanical high-speed stripping equipment, continuously high-density shearing and peeling for 6 hours under the conditions of rotation speed 3000 rpm, normal ...

Embodiment 2

[0042] A high-performance graphene composite silver paste consists of the following raw materials in terms of mass percentage: 15% graphite powder, 55% nano-silver paste, 4% glass powder, 1.5% dendritic organic molecules, and 24.5% organic solvent.

[0043] Wherein: the dendritic organic molecule is polyethylene glycol-polyamide-amine.

[0044] The glass powder is alumina.

[0045] The organic solvent is a mixture of glycerin: terpineol: turpentine in a mass ratio of 2:1:1.

[0046] A preparation method for high-performance graphene composite silver paste, comprising the following steps:

[0047] (1) Weigh graphite powder, nano-silver paste, silicon dioxide, polyamide-amine and organic solvent in sequence according to the above ratio;

[0048] ⑵Mix polyethylene glycol-polyamide-amine and graphite powder in an organic solvent, stir evenly, and then add mechanical high-speed stripping equipment, continuous high-density shearing and peeling at a speed of 3000 rpm, normal temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com