A method for preparing and transferring ultrathin large size lead iodide nanosheets

A lead iodide, large-scale technology is applied in the field of preparation and transfer of ultra-thin and large-scale lead iodide nanosheets, which can solve the problems of difficulty in preparing nanosheets, complicated operation, poor repeatability, etc., and achieves good controllability, Reproducible, high-yield results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

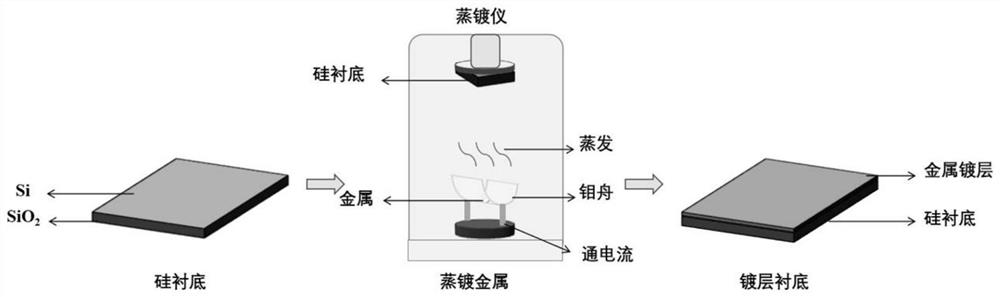

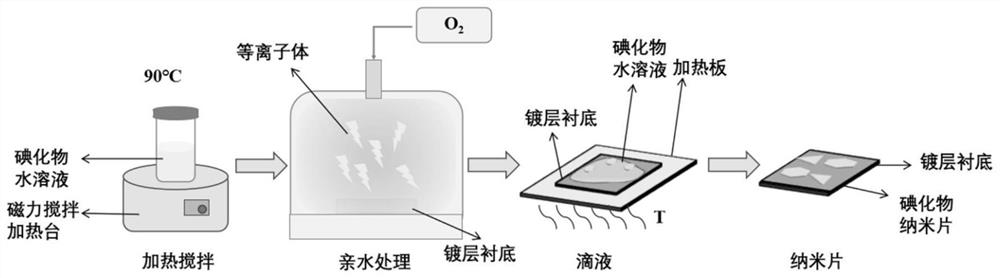

[0031] 10mg PbI 2 The particles were mixed with 10 ml of ultrapure water, and stirred for 6 h on a heating table with a temperature of 90 °C and a rotation speed of 300 rmp to obtain PbI with a concentration of 1 mg / ml 2Supersaturated aqueous solution; then cut the silicon substrate into a size of 1cm*1cm, and clean it, and then use an evaporation apparatus to vapor-deposit metal Cr-30nm on the clean silicon substrate to obtain a Cr-coated substrate; the Cr-coated lining The bottom is placed in a plasma cleaner and fed with O 2 Carry out the hydrophilic treatment for 300s of cleaning, and then place the hydrophilic treated Cr-plated substrate on a hot stage at 40 °C for constant temperature maintenance, and then use a pipette to remove 5 ul of PbI. 2 The supersaturated water solution was dropped on the Cr coating substrate. After the solution was dried, the temperature was increased to 150 °C for 2 min, and PbI with a size of 60 μm and a thickness of 3 nm could be prepared. ...

Embodiment 2

[0033] 12mg PbI 2 The particles were mixed with 10 ml of ultrapure water, and stirred for 24 h on a heating table with a temperature of 90 °C and a rotation speed of 300 rpm to obtain PbI with a concentration of 1.2 mg / ml 2 Supersaturated aqueous solution; then cut the silicon substrate into a size of 5mm*5mm, and clean it, and then use an evaporation apparatus to evaporate metal Cr-5nm / Au-20nm on the clean silicon substrate to obtain a Cr / Au coating substrate ; The Cr / Au coating substrate is placed in a plasma cleaner and fed with N 2 The hydrophilic treatment was carried out for 400s of cleaning, and then the Cr / Au plated substrate that had been hydrophilic treated was placed on a hot stage at 40 °C for constant temperature maintenance, and then the volume of 2ul of PbI was transferred with a pipette gun. 2 The supersaturated aqueous solution was dropped on the Cr / Au coating substrate, and after the solution was dried, the temperature was increased to 180 °C for 2 minutes, ...

Embodiment 3

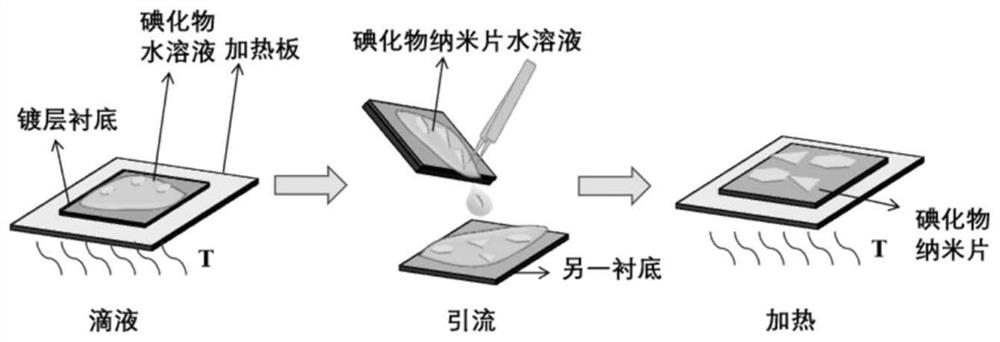

[0035] 15mg PbI 2 The particles were mixed with 10 ml of ultrapure water, and stirred for 6 h on a heating table with a temperature of 90 °C and a rotation speed of 350 rmp to obtain PbI with a concentration of 1.5 mg / ml 2 Supersaturated aqueous solution; then cut the silicon substrate into a size of 1.5cm*1.5cm and clean it; then use an evaporation apparatus to evaporate metal Cr-5nm / Au-50nm on the clean silicon substrate to obtain a Cr / Au coating lining The Cr / Au plated substrate was placed in a plasma cleaning apparatus and the air was passed through to perform a hydrophilic treatment for 300 s. Keep at constant temperature; then use a pipette to transfer a volume of 15ul of PbI 2 The supersaturated aqueous solution was dropped on the Cr / Au plated substrate, and the PbI on the surface of the solution on the Cr / Au plated substrate with tweezers 2 The nanosheets are drained onto the ultra-thin carbon film; after the solution is dried, heat treatment at 105 °C for 1 min to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com