Method for preparing epoxypropane through direct epoxidation of propylene

A technology of epoxidation and epoxidation reaction, applied in the direction of organic chemistry, etc., can solve the problem of short service life of the catalyst, and achieve the effect of prolonging the service life, no risk of explosion and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment is used to illustrate the method for the direct epoxidation of propylene provided by the invention

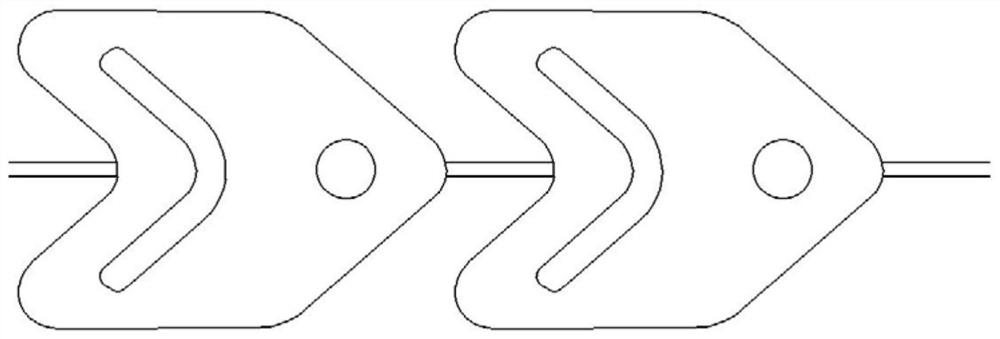

[0077] In a tubular reactor, relative to a 10ml reactor, 0.20g of Au@TS-1 molecular sieve catalyst (the loading of Au is 1% by weight) and 20g of quartz sand were layered into the reactor, as shown in the attached Figure 5 Shown in (c), wherein, the layer height ratio of the catalyst layer and the quartz sand layer is 1:2, and the catalyst layer and the inert filler layer are each independently 15 layers / cm, and carry out the direct epoxidation reaction of propylene gas phase .

[0078] Among them, raw material gas H 2 , O 2 、C 3 h 6 , Propane enters the mixer and mixes and then enters the preheater, preheats to 160°C and then enters the tubular reactor, the reaction space velocity is 9000ml g cat -1 h -1 , the reaction pressure of the control system is 0.15MPa, at 0.8℃min -1 The speed program was heated up to 200°C, and after the reaction was st...

Embodiment 2

[0080] This embodiment is used to illustrate the method for the direct epoxidation of propylene provided by the invention

[0081] In a tubular reactor, relative to a 10ml reactor, 0.20g of Au@TS-1 molecular sieve catalyst (the loading of Au was 1% by weight) and 18g of quartz sand were layered into the reactor, as shown in the attached Figure 5 As shown in middle (c), wherein, the layer height ratio of the catalyst layer and the quartz sand layer is 1:1.5, and the catalyst layer and the inert filler layer are each independently 10 layers / cm, and the gas phase direct epoxidation reaction of propylene is carried out .

[0082] Among them, raw material gas H 2 , O 2 、C 3 h 6 , Propane enters the mixer and mixes and then enters the preheater, preheats to 130°C and then enters the tubular reactor, the reaction space velocity is 15000ml g cat -1 h -1 , the reaction pressure of the control system is 0.05MPa, at 1.5℃min -1 The speed program was heated up to 170°C, and after ...

Embodiment 3

[0084] This embodiment is used to illustrate the method for the direct epoxidation of propylene provided by the invention

[0085] In a tubular reactor, relative to a 10ml reactor, 0.20g of Au@TS-1 molecular sieve catalyst (the loading of Au is 1% by weight) and 22g of quartz sand were layered into the reactor, as shown in the attached Figure 5 In (c), wherein, the layer height ratio of the catalyst layer and the quartz sand layer is 1:2.5, and the catalyst layer and the inert filler layer are each independently 20 layers / cm, and the gas phase direct epoxidation reaction of propylene is carried out .

[0086] Among them, raw material gas H 2 , O 2 、C 3 h 6, Propane enters the mixer and mixes and then enters the preheater, preheats to 100°C and then enters the tubular reactor, the reaction space velocity is 2000ml g cat -1 h -1 , the reaction pressure of the control system is 0.25MPa, at 1.2℃min -1 The speed program was raised to 120 DEG C, and after the reaction was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com