Early-strength polycarboxylic acid water reducing agent for subway segment and preparation method of early-strength polycarboxylic acid water reducing agent

A subway segment, early-strength technology, applied in the field of concrete admixtures, can solve the problems of limited use and slow development of concrete strength, and achieve the effects of promoting hydration, improving the convenience of colleges and universities, and strong cross-linking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

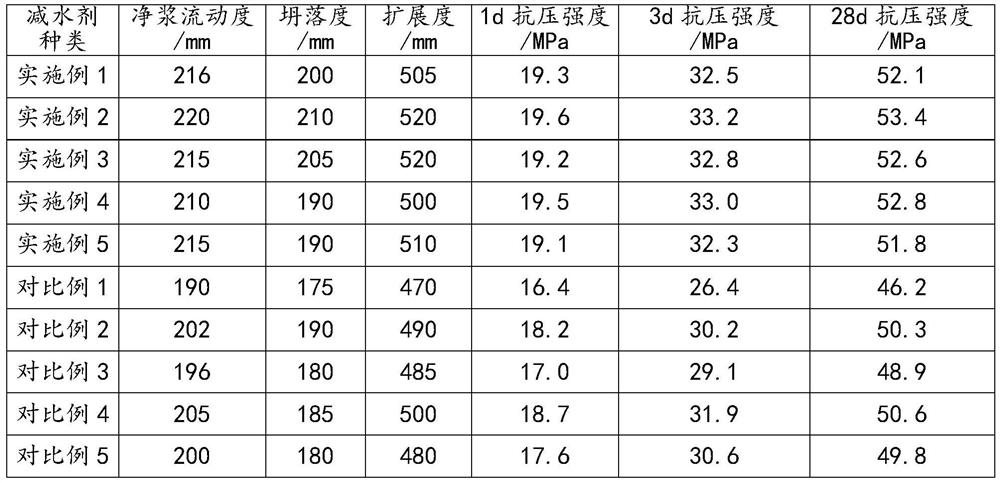

Examples

Embodiment 1

[0050] Step 1. Add 150 parts of modified polyether macromonomer, 10 parts of vinyltriacetoxysilane, 2.5 parts of sodium hypophosphite and 150 parts of water into a three-necked flask, turn on the high-speed stirring device, and the stirring speed is at 350rpm. Heat to 63°C and stir to form a monomer mixed solution;

[0051] Wherein, the preparation step of the modified polyether macromonomer is as follows: 200 parts of 6000 molecular weight isopentenol polyoxyethylene ether, 20 parts of methacrylic acid and 180 parts of water are placed in a nitrogen-protected high-speed shear stirring device, Add 22 parts of N-methylolacrylamide, the reaction temperature is 70° C., and continue the reaction for 2 hours to obtain a modified polyether macromonomer.

[0052] After mixing 1.2 parts of ammonium persulfate with 20 parts of water, add it to the first automatic dripping device, and adjust the dripping time to be 180min;

[0053] Mix 25 parts of methacryloyloxyethyl phosphonate, 8 pa...

Embodiment 2

[0057] Step 1. Add 160 parts of modified polyether macromonomer, 10 parts of vinyltriacetoxysilane, 2.8 parts of sodium hypophosphite and 160 parts of water into a three-necked flask, turn on the high-speed stirring device, and the stirring speed is at 350rpm, while Heat to 63°C and stir to form a monomer mixed solution;

[0058] Wherein, the preparation step of the modified polyether macromonomer is as follows: 200 parts of 6000 molecular weight isopentenol polyoxyethylene ether, 15 parts of methacrylic acid and 180 parts of water are placed in a nitrogen-protected high-speed shear stirring device, Add 20 parts of N-methylolacrylamide, the reaction temperature is 70° C., and continue the reaction for 2 hours to obtain a modified polyether macromonomer.

[0059] After mixing 1.2 parts of ammonium persulfate with 20 parts of water, add it to the first automatic dripping device, and adjust the dripping time to be 180min;

[0060] Mix 22 parts of methacryloyloxyethyl phosphonate...

Embodiment 3

[0064] Step 1. Add 170 parts of modified polyether macromonomer, 12 parts of vinyltriacetoxysilane, 2.5 parts of sodium hypophosphite and 170 parts of water into a three-necked flask, turn on the high-speed stirring device, and the stirring speed is at 350rpm, while Heat to 63°C and stir to form a monomer mixed solution;

[0065] Wherein, the preparation step of the modified polyether macromonomer is as follows: 200 parts of 6000 molecular weight isopentenol polyoxyethylene ether, 18 parts of methacrylic acid and 180 parts of water are placed in a nitrogen-protected high-speed shear stirring device, Add 22 parts of N-methylolacrylamide, the reaction temperature is 70° C., and continue the reaction for 2 hours to obtain a modified polyether macromonomer.

[0066] After mixing 0.8 parts of ammonium persulfate with 20 parts of water, add it to the first automatic dripping device, and adjust the dripping time to be 180min;

[0067] Mix 20 parts of methacryloyloxyethyl phosphonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com