Thermal pyoil to a gas fed cracker furnace

A technology of cracker and pyrolysis oil, which is applied in the field of preparation of one or more olefins and preparation of olefins, and can solve the problems of reducing the yield of pyrolysis oil olefins, slagging, overcracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

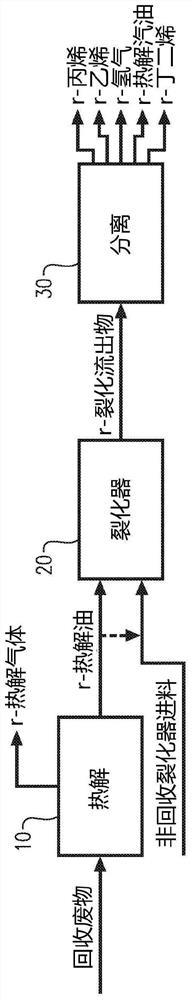

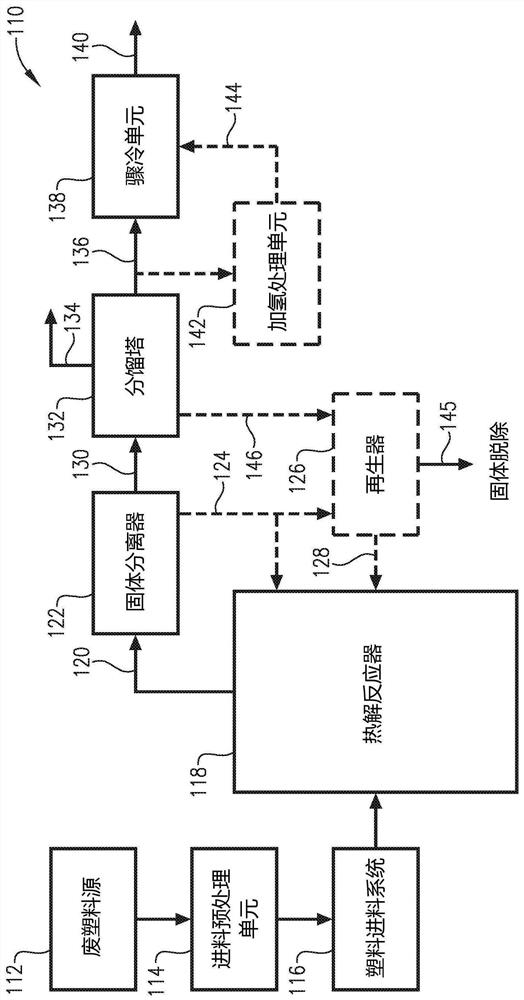

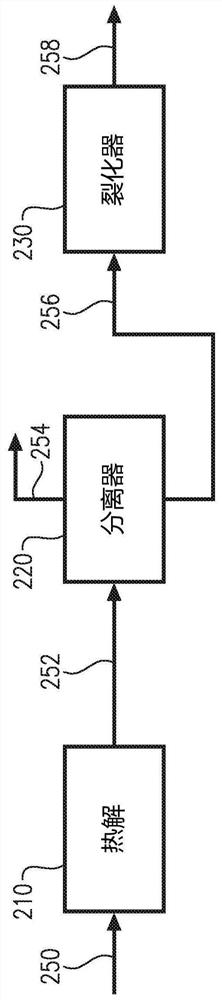

Method used

Image

Examples

example

[0490] r-pyrolysis oil example 1-4

[0491] Table 1 shows the composition of r-pyrolysis oil samples by gas chromatography analysis. r-pyrolysis oil samples were prepared from waste high- and low-density polyethylene, polypropylene, and polystyrene materials. Sample 4 is a laboratory distilled sample where hydrocarbons larger than C21 were removed. The boiling point curves for these materials are shown in Figure 13-16 middle.

[0492] Table 1. Gas chromatographic analysis of r-pyrolysis oil examples

[0493]

[0494]

[0495]

[0496]

example 5

[0499] Example 5. r-pyrolysis oil boiling at least 90% at 350°C, 50% boiling between 95°C and 200°C, at least 10% boiling at 60°C.

[0500] A 250 g sample of r-pyrolysis oil from Example 3 was distilled through a 30-tray glass Oldershaw column equipped with a glycol-cooled condenser, a thermowell containing a thermometer, and a magnet-operated reflux regulated by an electronic timer. controller. Batch distillation was performed at atmospheric pressure with a reflux ratio of 1:1. Liquid fractions were collected every 20 mL, and the overhead temperature and mass were recorded to construct Figure 17 Boiling curve shown. The distillation was repeated until approximately 635 g of material was collected.

example 6

[0501] Example 6. r-pyrolysis oil boiling at least 90% at 150°C, 50% boiling between 80°C and 145°C, and at least 10% boiling at 60°C.

[0502] A 150 g sample of r-pyrolysis oil from Example 3 was distilled through a 30-tray glass Oldershaw column equipped with a glycol-cooled condenser, a thermowell containing a thermometer, and a magnet-operated reflux regulated by an electronic timer. controller. Batch distillation was performed at atmospheric pressure with a reflux ratio of 1:1. Liquid fractions were collected every 20 mL, and the overhead temperature and mass were recorded to construct Figure 18 Boiling curve shown. The distillation was repeated until approximately 200 g of material was collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com