Thin-wall cylinder structure reinforcing rib characteristic stirring friction additive manufacturing method and equipment

An additive manufacturing and friction stir technology, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of low mechanical properties of formed parts, difficult high-quality forming, deformation of thin-walled structures, etc., to improve the utilization rate of materials , The effect of reducing the processing time and improving the forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

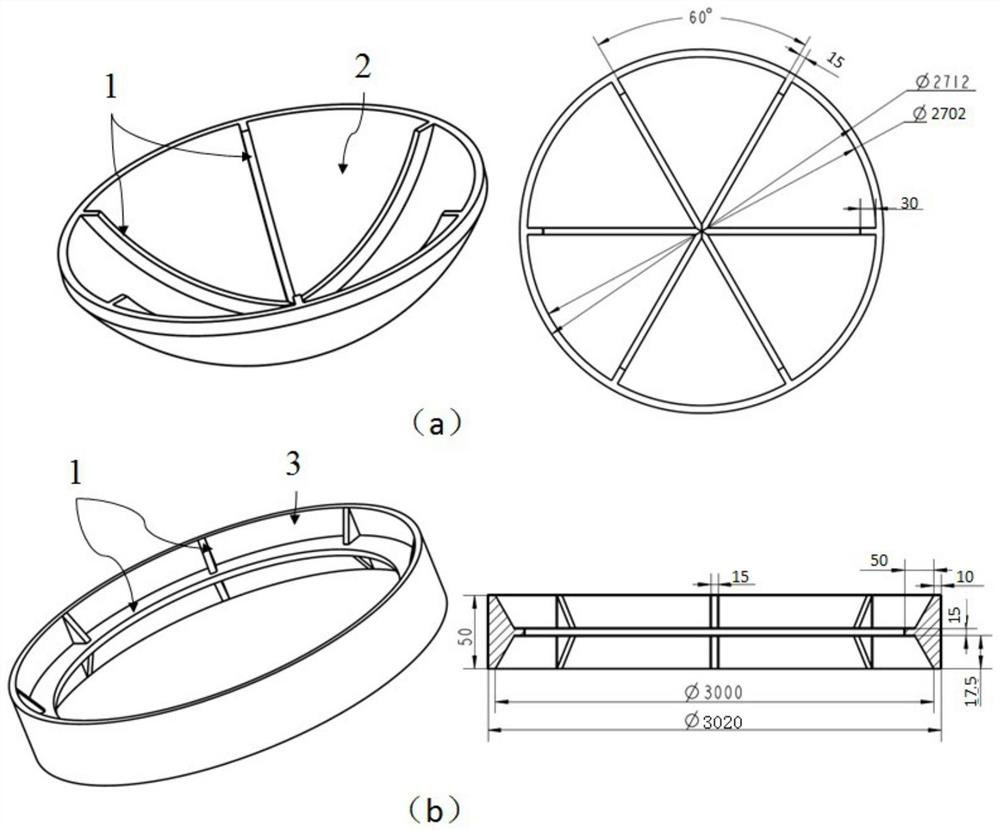

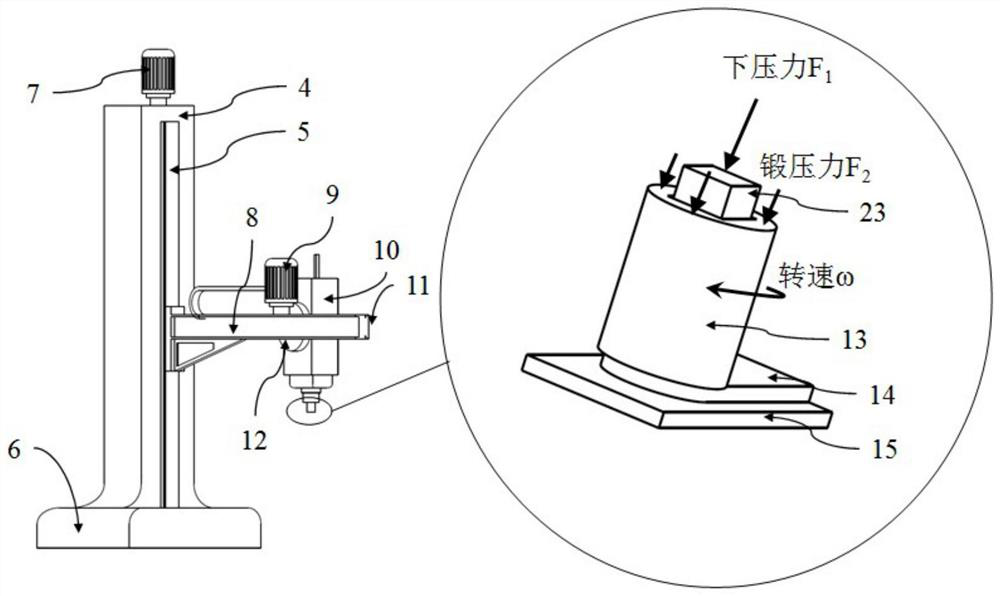

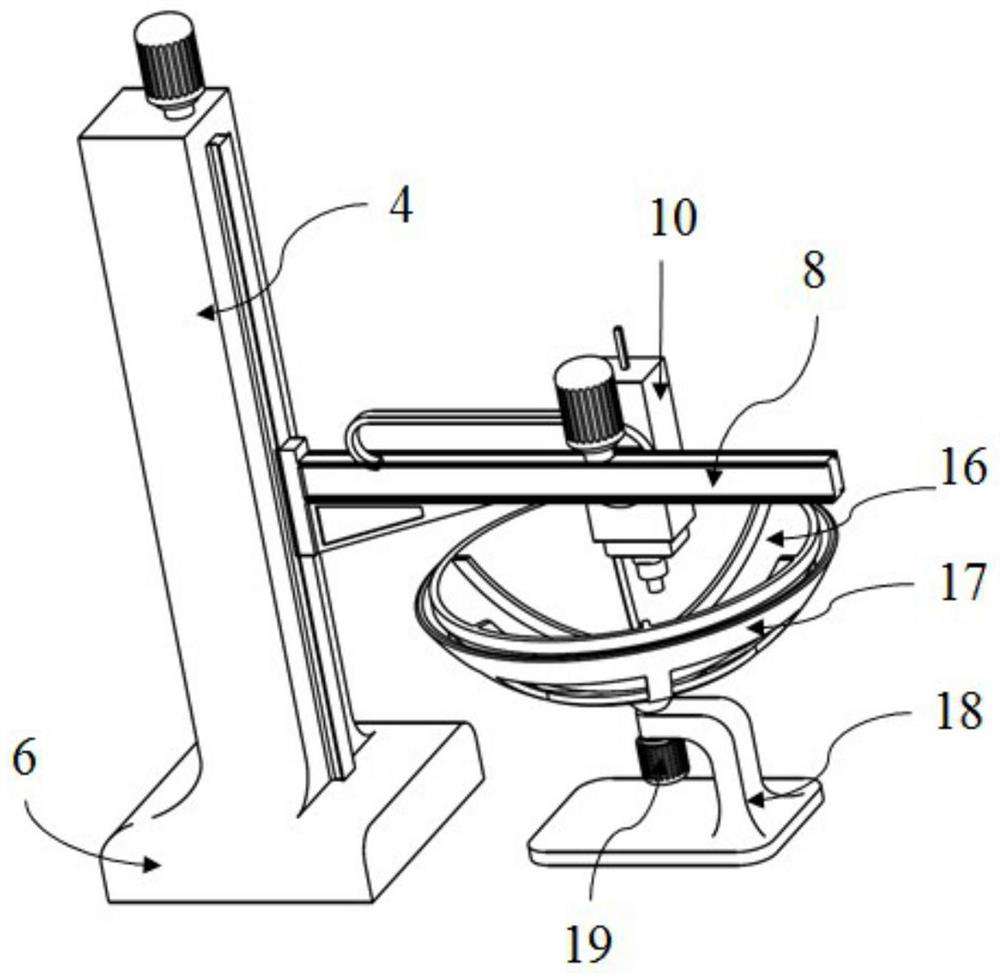

[0038] Such as figure 1 The aluminum alloy cylinder bottom structure shown in a has an outer diameter of 2712mm, a cylinder wall thickness of 5mm, a reinforcement rib structure width of 15mm, and a height of 30mm. The three reinforcement ribs are evenly distributed at 60°, such as figure 2As shown, the friction stir additive manufacturing method and its equipment are used for forming. The coaxially conveyed bar material 23 enters the hollow stirring tool 13, and a huge forging pressure is generated between the substrate and the substrate under the action of the downward force F1. At the same time, the hollow stirring tool 13 rotates at a high speed to drive The square bar 23 rubs against the substrate 15 to generate heat, and then plasticizes. The plasticized material forms a surfacing layer 14 under the action of the shoulder forging pressure F2 of the stirring tool. The friction stir additive manufacturing equipment includes at least a column 4, a longitudinal guide rail 5, ...

Embodiment 2

[0047] Such as figure 1 The structure of the aluminum alloy cylinder section shown in b has an outer diameter of 3020 mm, a cylinder wall thickness of 10 mm, a rib structure width of 15 mm, a circumferential rib height of 50 mm, and eight triangular plate ribs in the radial direction at 45° evenly distributed, with a height of 30 mm. figure 2 As shown, the friction stir additive manufacturing method and its equipment are used for forming. The coaxially conveyed bar material 23 enters the hollow stirring tool 13, and a huge forging pressure is generated between the substrate and the substrate under the action of the downward force F1. At the same time, the hollow stirring tool 13 rotates at a high speed to drive The square bar 23 rubs against the substrate 15 to generate heat, and then plasticizes. The plasticized material forms a surfacing layer 14 under the action of the shoulder forging pressure F2 of the stirring tool. The friction stir additive manufacturing equipment incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com