Environment-friendly high-performance airtight concrete and preparation method thereof

A concrete, high-performance technology, applied in the field of concrete, can solve the problems of high production cost of air-tight concrete, increase the void ratio, increase the air permeability coefficient, etc., achieve good environmental and economic benefits, improve strength and compactness, reduce The effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

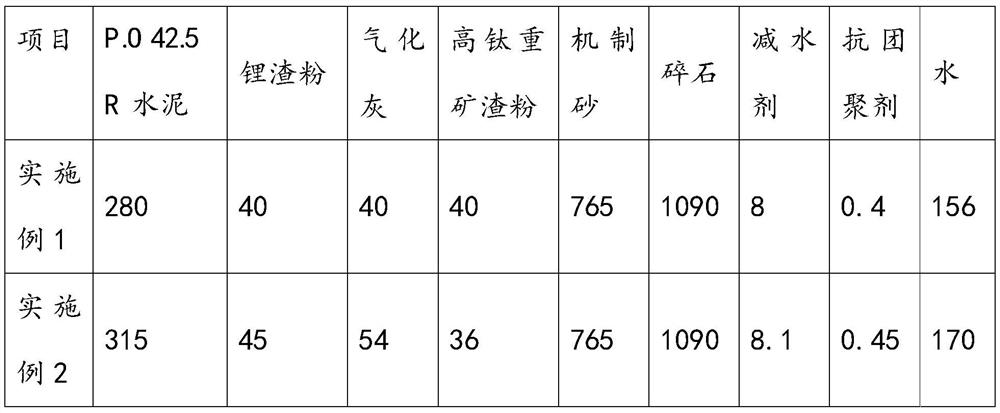

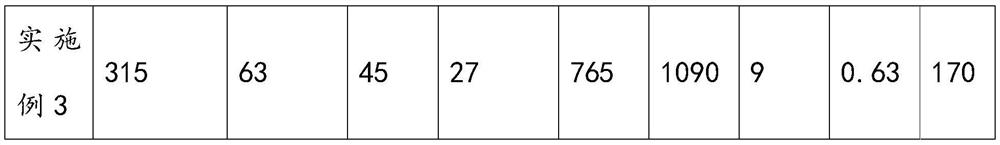

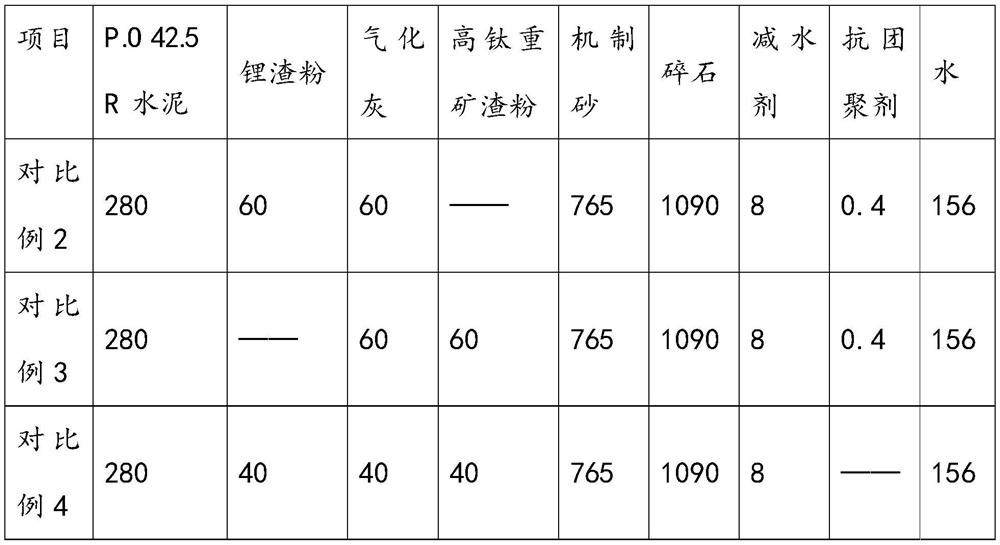

Examples

preparation example Construction

[0030] Environmental protection type high-performance airtight concrete of the present invention, its preparation method comprises the following steps:

[0031] S1. Weigh the measured components, mix the modified polycarboxylate water reducer into water to obtain a mixed solution, divide the mixed solution into three parts, mix the sand, gravel and one part of the mixed solution together, and The aggregate is wetted to obtain a mixture;

[0032] S2. Mix and stir other raw materials and two parts of the mixed solution with the mixture of S1 for 30-90 seconds to obtain an admixture, which is obtained after pouring and solidification.

[0033] In the above-mentioned airtight concrete, the anti-agglomeration agent is preferably composed of trimethoxysilane, fatty alcohol polyoxyethylene ether and sodium tripolyphosphate, and the mass ratio of the three components is 1:2:1; modified polycarboxylic acid The water reducer is obtained by adding 6-10% white carbon black in the mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com