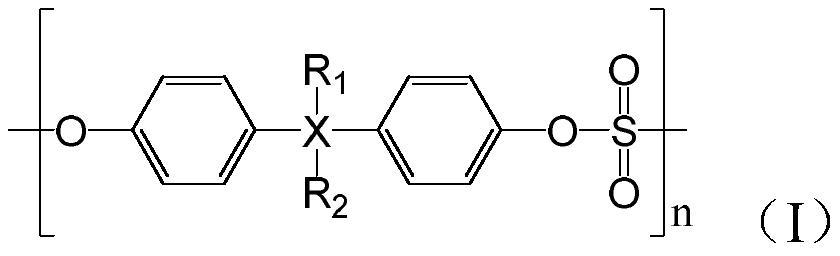

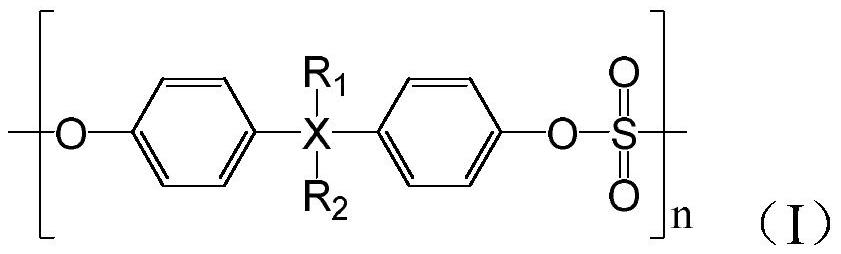

Preparation method of polysulfate type epoxy resin

A polysulfate and epoxy resin technology, applied in the field of polymer materials, can solve problems such as mechanical property defects, and achieve the effects of simple and stable reaction process, less by-products, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the polysulfate type epoxy resin provided by the present embodiment may further comprise the steps:

[0038] 1. Preparation of low molecular weight polysulfate

[0039] (1-1) First put 400g of bisphenol A, 300g of bisphenol A bissulfonyl fluoride, 1.2kg of sulfolane, and 250g of potassium carbonate into a 50L autoclave, and react at 170°C for 4h to prepare polysulfate.

[0040] (1-2) After the polysulfate was precipitated, it was boiled twice in ethanol at 100°C, and boiled in high-purity water three times at 140°C, filtered and dried at 80°C, and the number average molecular weight Mn=3562g / mol was measured.

[0041] 2. Preparation of Epoxy Resin

[0042] (2-1) Take 500 g of the treated bisphenol A polysulfate, add 2.5 kg of epichlorohydrin as a solvent, and heat and stir at 80° C. for 2 hours to fully dissolve the polysulfate.

[0043] (2-2) Add 15 g of ring-opening catalyst tetrabutylammonium bromide to the solution obtained in step (2-1),...

Embodiment 2

[0048] The preparation method of the polysulfate type epoxy resin provided by the present embodiment may further comprise the steps:

[0049] 1. the preparation of low molecular weight polysulfate, with embodiment 1

[0050] 2. Preparation of Epoxy Resin

[0051](2-1) Take 500 g of the treated bisphenol A polysulfate, add 3.0 kg of epichlorohydrin as a solvent, and heat and stir at 80° C. for 2 hours to fully dissolve the polysulfate.

[0052] (2-2) Add 15 g of tetrabutylammonium bromide, a ring-opening catalyst, to the solution obtained in step (2-1), and stir at 90° C. for 3 hours.

[0053] (2-3) Add ring-closing catalyst sodium hydroxide solution to the solution obtained in step (2-2) with stirring, the concentration of sodium hydroxide solution is 30wt%, and then stir and heat at 70° C. for 3 hours.

[0054] (2-4) Pour the solution obtained in step (2-3) into 5 L of methanol for sedimentation, and then take out the precipitate.

[0055] (2-5) Add the precipitate obtaine...

Embodiment 3

[0057] The preparation method of the polysulfate type epoxy resin provided by the present embodiment may further comprise the steps:

[0058] 1. the preparation of low molecular weight polysulfate, with embodiment 1

[0059] 2. Preparation of Epoxy Resin

[0060] (2-1) Take 500 g of the treated bisphenol A polysulfate, add 3.0 kg of epichlorohydrin as a solvent, and heat and stir at 80° C. for 2 hours to fully dissolve the polysulfate.

[0061] (2-2) Add 15 g of tetrabutylammonium bromide, a ring-opening catalyst, to the solution obtained in step (2-1), and stir at 90° C. for 3 hours.

[0062] (2-3) Add ring-closing catalyst sodium hydroxide solution with stirring to the solution obtained in step (2-2). The concentration of the sodium hydroxide solution is 20 wt%, and then stir and heat at 70° C. for 3 hours.

[0063] (2-4) Pour the solution obtained in step (2-3) into 5 L of methanol for sedimentation, and then take out the precipitate.

[0064] (2-5) Add the precipitate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com