Steel slag-based binary composite phase change material capable of melting snow and removing ice and preparation method of steel slag-based binary composite phase change material

A composite phase change material and a technology for phase change materials, which are applied in the field of steel slag-based binary composite phase change materials and their preparation, can solve the problems of difficult repair of heating devices, corroded road surfaces, long periods of time for melting snow and deicing, etc., so as to alleviate the cycle Effect of thermal stress damage, preventing environmental temperature drop, and avoiding thermal fatigue cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A steel slag-based binary composite phase change material capable of melting snow and deicing:

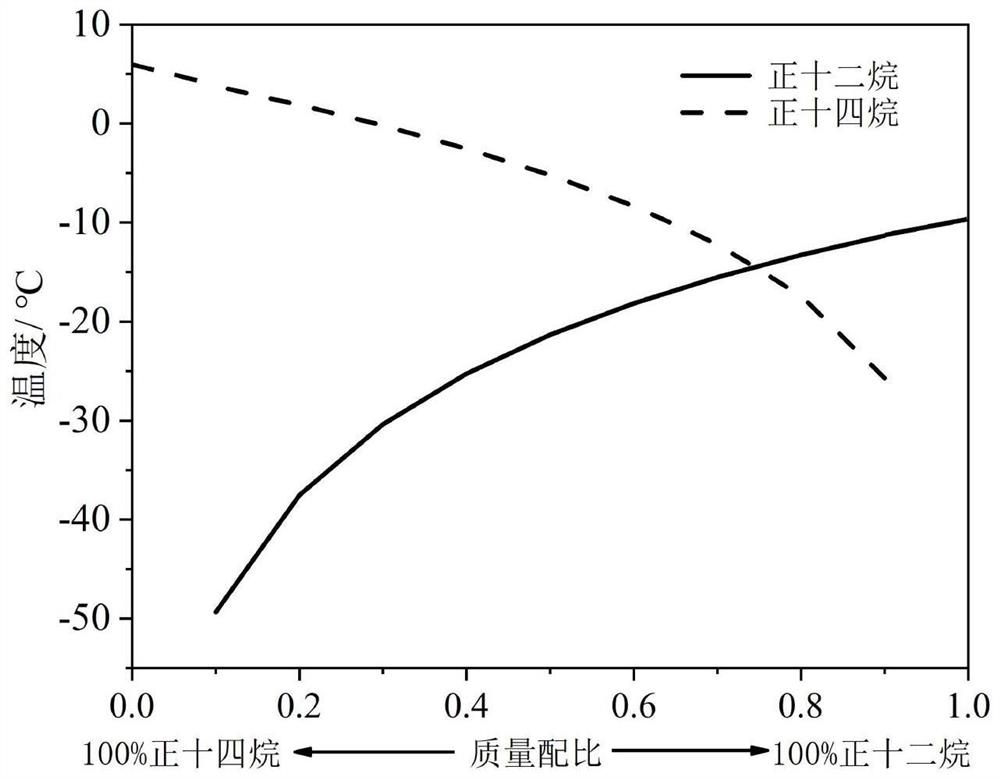

[0041] 1. Select phase change material A as n-dodecane, with a melting point of -9.6°C and a latent heat of phase change of 142J / g, and phase change material B as n-tetradecane with a melting point of 5.5°C and a latent heat of phase change of 227J / g. According to the mass ratio of n-dodecane to n-tetradecane M1:M2=90:10; 80:20; 70:30; 60:40; 50:50; 40:60; 30:70; 20:80; 10: 90 were blended to obtain nine groups of samples, through Calculate the eutectic point of n-dodecane and n-tetradecane binary composite phase change materials, the calculation results are as follows figure 1 As shown, the optimum mass ratio of n-dodecane to n-tetradecane M1:M2=76:24 is obtained at the eutectic point of -15.2°C.

[0042] pass meter Calculate the phase change latent heat of n-dodecane and n-tetradecane binary composite phase change materials, and the calculation result is 43.06J / g, so ...

Embodiment 2

[0051] A steel slag-based binary composite phase change material capable of melting snow and deicing:

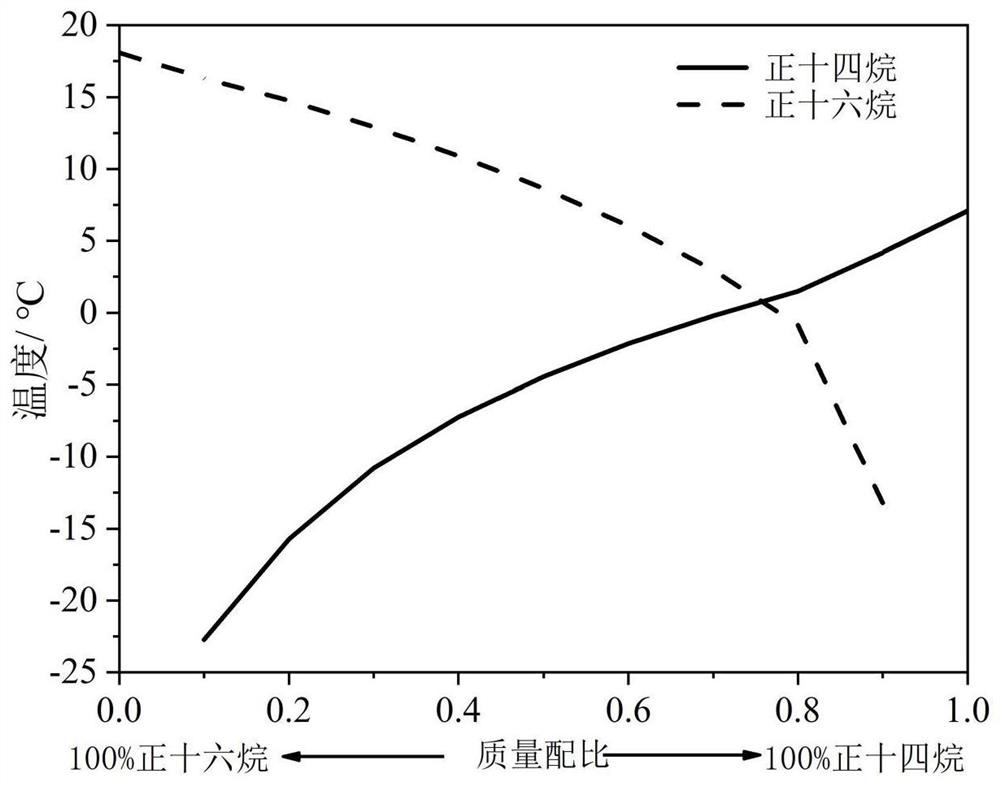

[0052] 1. Select phase change material A as n-tetradecane, melting point is 5.5°C, latent heat of phase change is 227J / g, phase change material B is n-hexadecane, melting point is 18°C, latent heat of phase change is 217J / g, according to The mass ratio of n-tetradecane to n-hexadecane M1:M2=90:10; 80:20; 70:30; 60:40; 50:50; 40:60; 30:70; 20:80; 10:90 Nine groups of samples were obtained by blending respectively. Calculate the eutectic point of n-tetradecane and n-hexadecane binary composite phase change materials, the calculation results are as follows figure 2 As shown, the optimum mass ratio of n-tetradecane to n-hexadecane M1:M2=69:31 is obtained at the eutectic point of 0.83°C.

[0053] pass meter Calculate the phase change latent heat of n-dodecane and n-tetradecane binary composite phase change materials, and the calculation result is 27.41J / g, so that it can me...

Embodiment 3

[0059] A steel slag-based binary composite phase change material capable of melting snow and deicing:

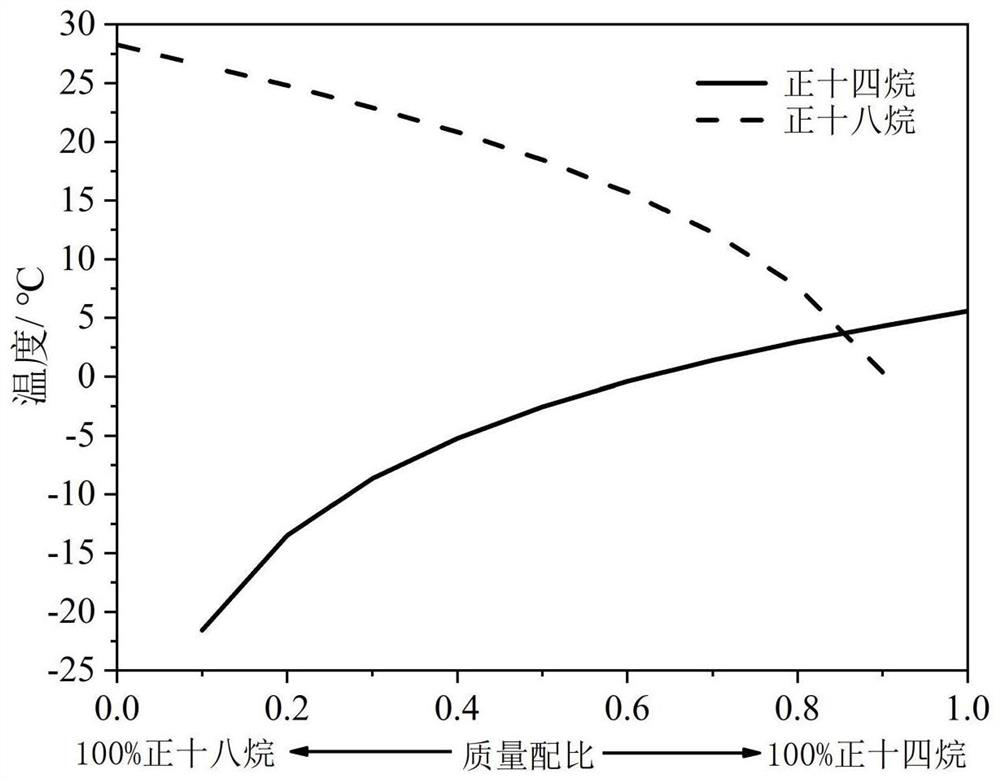

[0060] 1. Select phase change material A as n-tetradecane, with a melting point of 5.5°C and a latent heat of phase change of 227J / g, and phase change material B as n-octadecane with a melting point of 28.13°C and a latent heat of phase change of 246.29J / g. According to the mass ratio of n-tetradecane to n-octadecane M1:M2=90:10; 80:20; 70:30; 60:40; 50:50; 40:60; 30:70; 20:80; 10: 90 were blended to obtain nine groups of samples, through Calculate the eutectic point of n-tetradecane and n-octadecane binary composite phase change materials, the calculation results are as follows image 3 As shown, the optimum mass ratio of n-tetradecane to n-octadecane M1:M2=86:14 is obtained at the eutectic point of 4.2°C.

[0061] pass Calculate the phase change latent heat of n-tetradecane and n-octadecane binary composite phase change material, and the calculation result is 157.97J / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com