Method for regulating and controlling particle size and particle size distribution of ultra-high molecular weight polyethylene

An ultra-high molecular weight, polyethylene technology, applied in the field of preparing ultra-high molecular weight polyethylene catalysts, can solve the problems of unfavorable polyethylene fibers, unfavorable industrial production, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

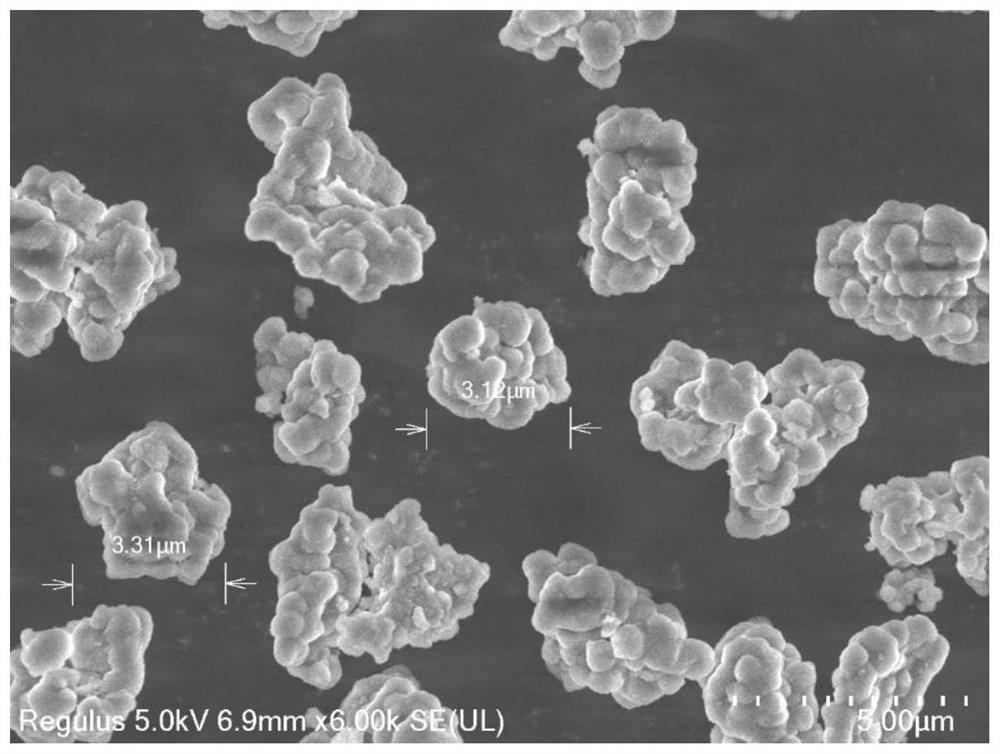

[0051] Preparation Example 1: Catalyst 1

[0052] Take 0.2mol of magnesium powder and place it in a 500mL three-necked flask replaced by nitrogen, add 100mL of decane, 0.02g of iodine, and a small amount of n-chlorobutane; heat to 75°C and stir for 2 hours, add dropwise 1mol of dry chlorine Replacing n-butane, an obvious reaction can be observed, continue to react for 3 hours, filter, and the gained solid is washed with hexane and dried to obtain a carrier, and the elemental analysis results show that its carrier is composed of: (MgCl 2 )(BuMgCl) 0.59 .

[0053] Heat 0.05mol (calculated as Mg) of the above-mentioned carrier, 20mL of decane and 26mL of isooctyl alcohol (0.167mol), heat to 130°C for 60 minutes, cool down to 65°C, and add 15mmol of γ-chloropropyltrimethoxyl at this temperature Silane (silane electron donor) and 15 mmol norbornene anhydride were reacted for 60 minutes, and cooled to room temperature. Slowly add dropwise to 200mL TiCl at -10°C for 90 minutes 4 ...

preparation example 2

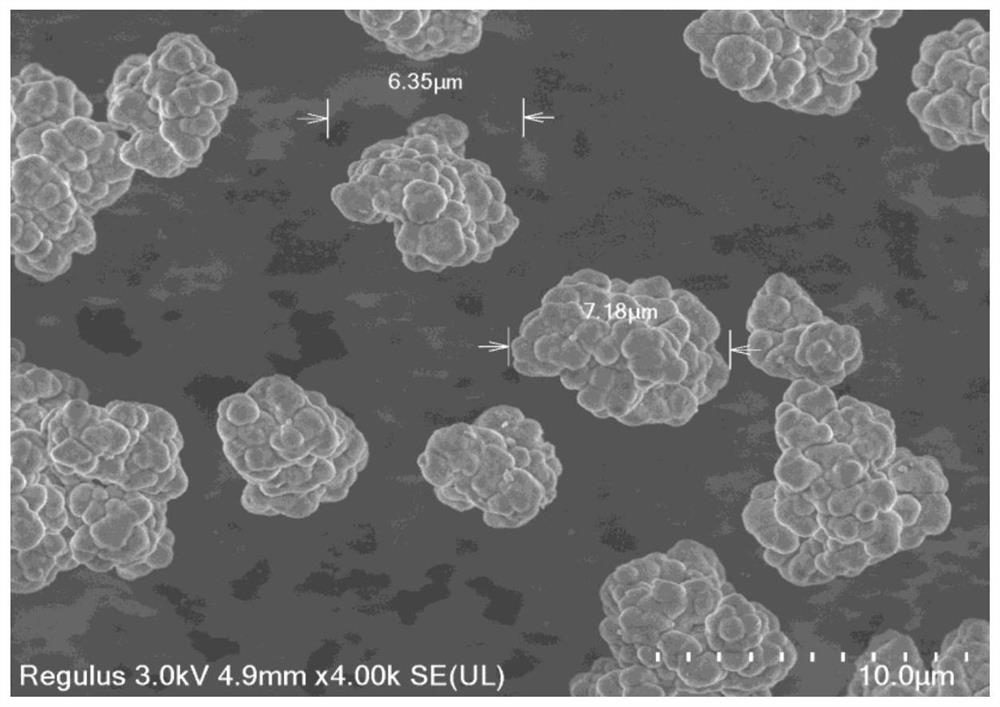

[0054] Preparation Example 2: Catalyst 2

[0055] The preparation of catalyst 2 was the same as that of preparation example 1, except that the stirring speed was 600 rpm. The elemental analysis of catalyst 2: Ti: 3.63%, Mg: 16.1%, Cl: 63.1%, Si: 1.2%; Particle size is 6.1 μ m (see figure 2 ).

preparation example 3

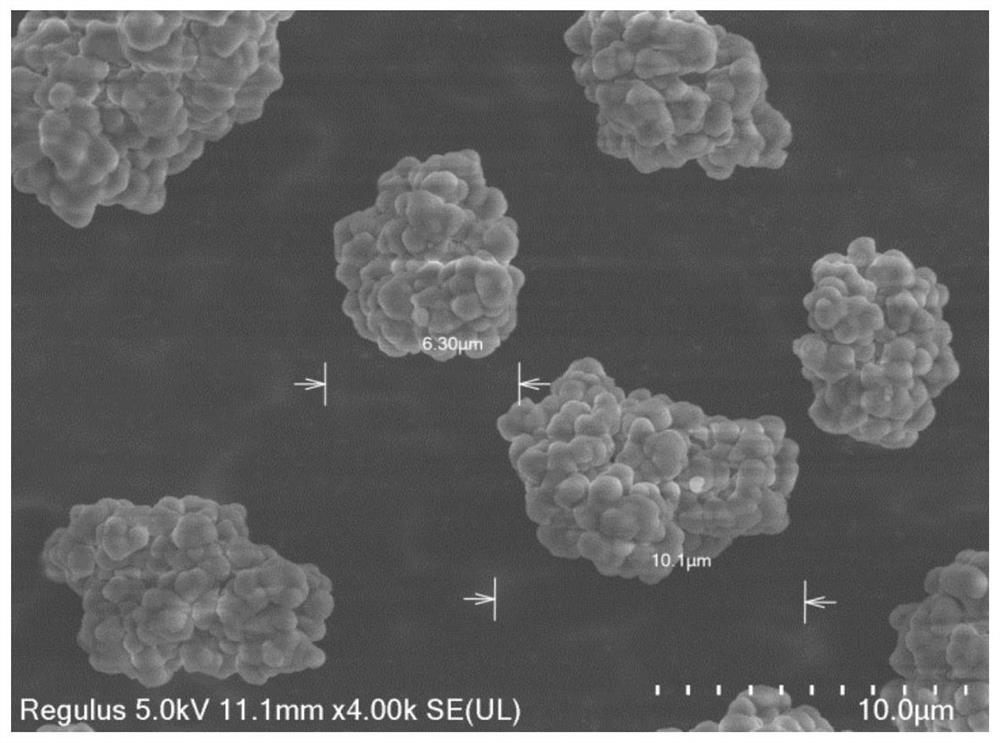

[0056] Preparation Example 3: Catalyst 3

[0057] The preparation of catalyst 3 was the same as that of preparation example 1, except that the stirring speed was 400 rpm. The elemental analysis of catalyst 3: Ti: 3.70%, Mg: 15.9%, Cl: 63.7%, Si: 1.23%; Particle size is 10.1 μ m (see image 3 ).

[0058] Adopt the catalyst of preparation example 1-3 to prepare ultrahigh molecular weight polyethylene

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com