Preparation method of binary metal platinum-palladium prismatic catalyst and application of binary metal platinum-palladium prismatic catalyst in direct methanol fuel cell

A binary metal, prismatic technology, applied in the field of fuel cell catalysts, can solve problems such as cost waste, and achieve the effect of simple synthesis steps, high activity and durability, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of binary metal platinum palladium prismatic catalyst, comprises the following steps:

[0029] (1) Take 0.05mmol (19.665mg) platinum acetylacetonate and 0.05mmol (15.232mg) palladium acetylacetonate as metal precursors, add them to a beaker containing 30mL of DMF and 200mg of TTAB, stir for 10-20min and mix well; then add 60mg carbon powder, ultrasonic 20min, stirring 20min to get a mixed solution;

[0030] (2) Move the mixed solution to a reaction kettle and react at 160°C for 24 hours; cool to room temperature, wash and dry to obtain a binary metal platinum palladium prismatic catalyst.

[0031] The noble metal in the prepared catalyst is in a low loading range, and the overall loading is about 20wt%.

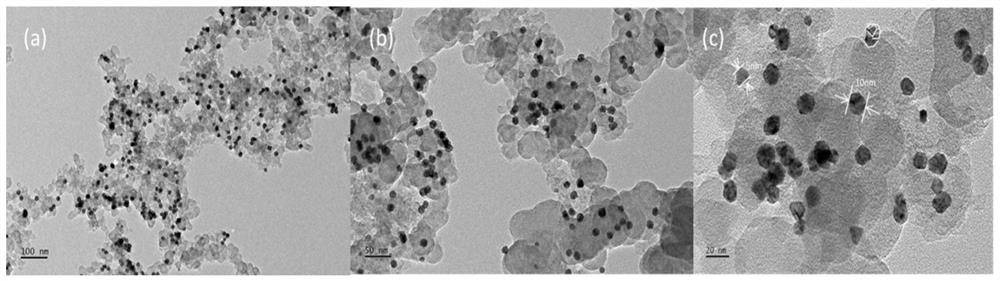

[0032] The prepared Pt-based metal nano-prism has a shape of a prism and a size of 5-10 nm.

[0033] Characterized by low power scanning transmission electron microscope and high power scanning transmission electron microscope:

[0034] ...

Embodiment 2

[0039] A kind of preparation method of binary metal platinum palladium direct methanol fuel cell catalyst, comprises the following steps:

[0040] (1) Take 0.05mmol (25.9mg) chloroplatinic acid hexahydrate and 0.05mmol (15.232mg) palladium acetylacetonate as metal precursors, add them to a beaker containing 30mL ultrapure water, 50mgAA and 200mg TTAB, and stir for 10-20min Mix evenly; then add 60mg of carbon powder, sonicate for 20 minutes, and stir for 20 minutes to obtain a mixed solution;

[0041] (2) Move the mixed solution to a reaction kettle and react at 200°C for 16 hours; cool to room temperature, wash and dry to obtain a binary metal platinum palladium prismatic catalyst.

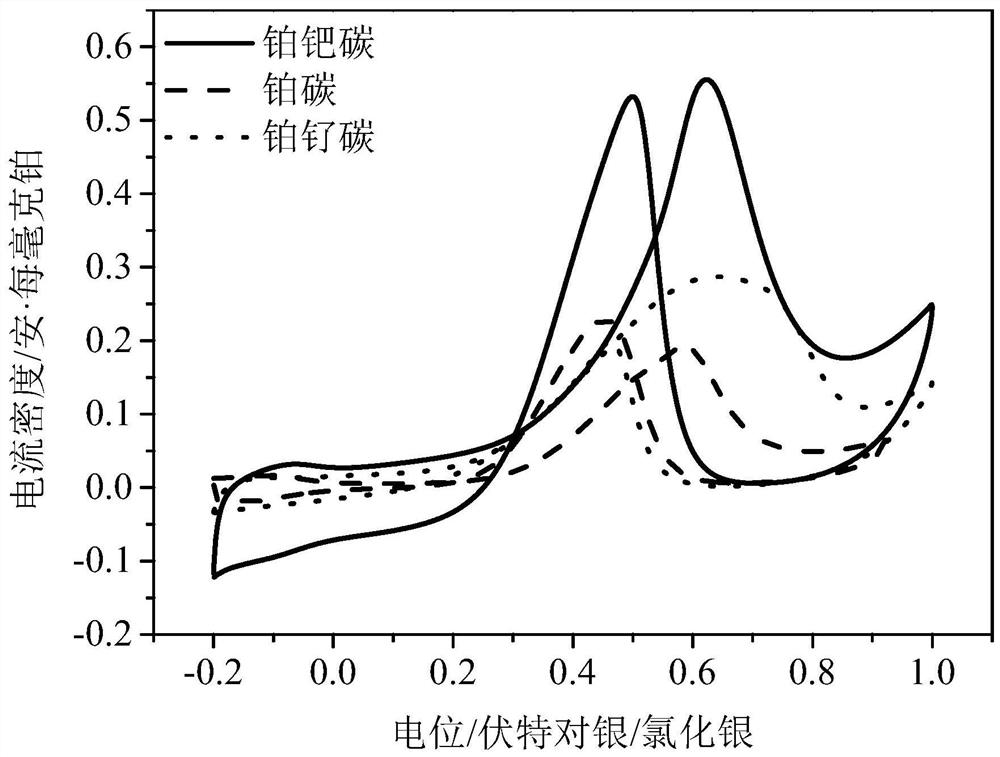

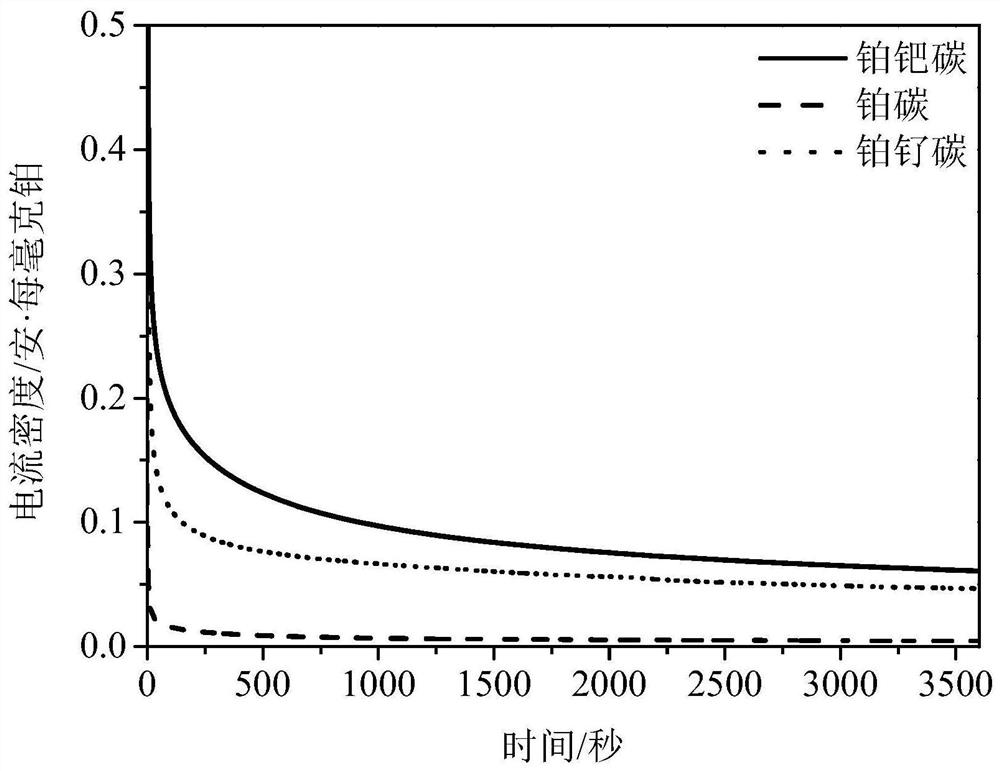

[0042] After electrochemical tests, the methanol oxidation activity of the obtained binary metal platinum palladium catalyst was 0.960 A·mg -1 , better than PtRu / C (0.574A mg -1 ) and standard Pt / C (0.386 A mg -1 ).

Embodiment 3

[0044] A kind of preparation method of binary metal platinum palladium direct methanol fuel cell catalyst, comprises the following steps:

[0045] (1) Take 0.05mmol (19.665mg) of platinum acetylacetonate and 0.05mmol (8.87mg) of palladium chloride as metal precursors, add them to a beaker containing 30mL of DMF and 200mg of CTAB, stir for 10-20min to mix well; then add 75mg carbon powder, ultrasonic 40min, stirring 40min to get a mixed solution;

[0046] (2) Move the mixed solution to a reaction kettle and react at 180°C for 18 hours; cool to room temperature, wash and dry to obtain a binary metal platinum palladium prismatic catalyst.

[0047] After electrochemical tests, the methanol oxidation activity of the obtained binary metal platinum-palladium catalyst was 0.980 A·mg -1 , better than PtRu / C (0.574 A mg -1 ) and standard Pt / C (0.386 A mg -1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com