Treatment method of chromate-containing solution

A treatment method and chromate technology, applied in water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of many chemical reagents, high cost of membrane separation, and sensitivity to interfering ions, and achieve a synthesis method. Simple, large-scale production, and efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present embodiment provides a kind of processing method containing chromate solution, comprises the following steps:

[0019] S1: Bi 2 o 3 preparation:

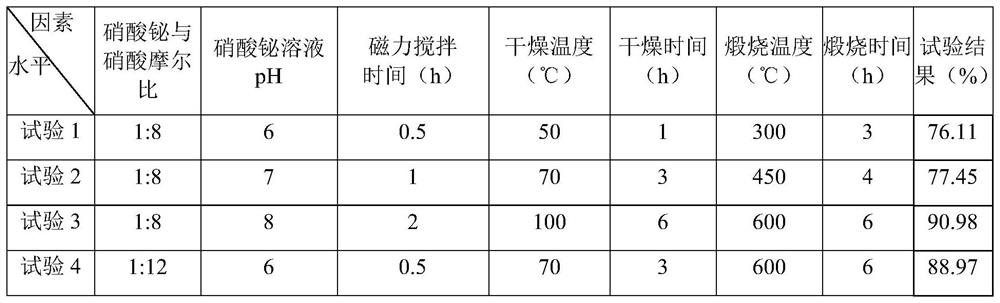

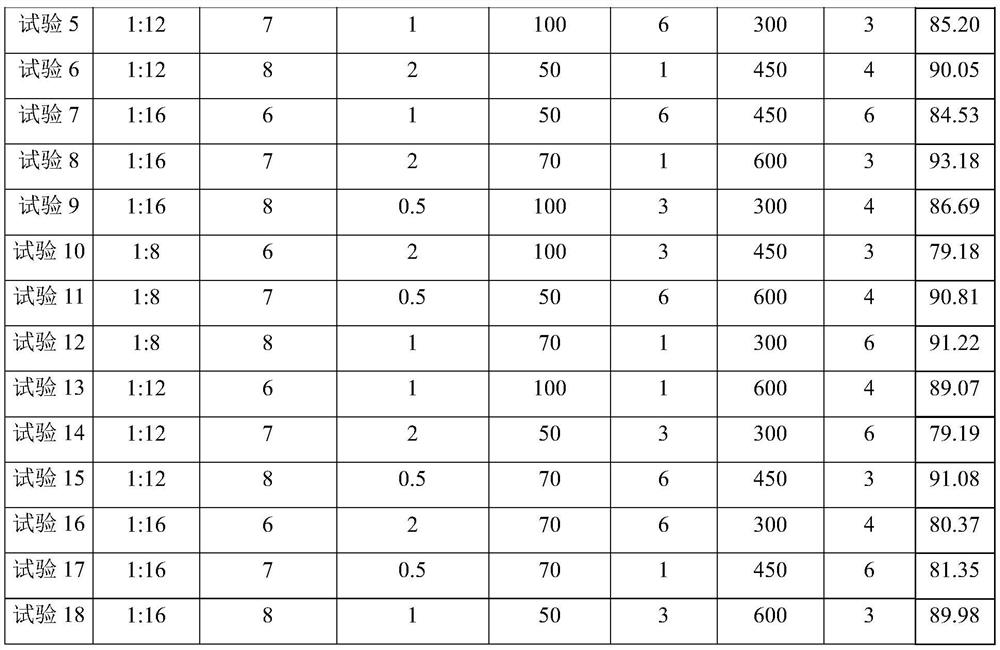

[0020] Dissolve bismuth nitrate in nitric acid solution at a molar ratio of 1:8, stir until dissolved, adjust the pH to 6-8 with lye, stir magnetically at room temperature for 0.5-2 hours, filter, and wash with absolute ethanol and distilled water 3-5 times, the product is dried at 50-100°C for 1-6 hours, and then calcined at 300-600°C for 3-6 hours to obtain yellow Bi2O3;

[0021] S2: BiOCl-Bi 2 o 3 preparation:

[0022] Add an appropriate amount of hydrochloric acid of a certain concentration to the prepared Bi 2 o 3 Ultrasonic reaction in 0.5-2h, the hydrochloric acid and Bi 2 o 3 The molar ratio is 0.1-1:1, after being centrifuged for 0.5-1h and then dried at a constant temperature of 50-100°C for 2-5h, BiOCl-Bi 2 o 3 heterojunction catalysts;

[0023] S3: Degradation of chromate:

[0024] 2g / L of ...

Embodiment 2

[0029] A processing method containing chromate solution, comprising the following steps:

[0030] S1: Bi 2 o 3 preparation:

[0031] Dissolve bismuth nitrate in nitric acid solution at a molar ratio of 1:12, stir well until dissolved, adjust the pH to 6-8 with lye, stir magnetically at room temperature for 0.5-2 hours, filter, and wash with absolute ethanol and distilled water 3-5 times, the product is dried at 50-100°C for 1-6 hours, and then calcined at 300-500°C for 3-6 hours to obtain yellow Bi2O3;

[0032] S2: BiOCl-Bi 2 o 3 preparation:

[0033] Add an appropriate amount of hydrochloric acid of a certain concentration to the prepared Bi 2 o 3 Ultrasonic reaction in 0.5-2h, the hydrochloric acid and Bi 2 o 3 The molar ratio is 0.1-1:1, after being centrifuged for 0.5-1h and then dried at a constant temperature of 50-100°C for 2-5h, BiOCl-Bi 2 o 3 heterojunction catalysts;

[0034] S3: Degradation of chromate:

[0035] 2g / L of BiOCl-Bi 2 o 3 Disperse the het...

Embodiment 3

[0040] A processing method containing chromate solution, comprising the following steps:

[0041] S1: Bi 2 o 3 preparation:

[0042] Dissolve bismuth nitrate in nitric acid solution at a molar ratio of 1:16, stir until dissolved, adjust the pH to 6-8 with lye, stir magnetically at room temperature for 0.5-2 hours, filter, and wash with absolute ethanol and distilled water 3-5 times, the product is dried at 50-100°C for 1-6 hours, and then calcined at 300-600°C for 3-6 hours to obtain yellow Bi2O3;

[0043] S2: BiOCl-Bi 2 o 3 preparation:

[0044] Add an appropriate amount of hydrochloric acid of a certain concentration to the prepared Bi 2 o 3 Ultrasonic reaction in 0.5-2h, the hydrochloric acid and Bi 2 o 3 The molar ratio is 0.1-1:1, after being centrifuged for 0.5-1h and then dried at a constant temperature of 50-100°C for 2-5h, BiOCl-Bi 2 o 3 heterojunction catalysts;

[0045] S3: Degradation of chromate:

[0046] 2g / L of BiOCl-Bi 2 o 3 Disperse the heterojunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com