Antistatic PVC board

A PVC board, antistatic technology, applied in the direction of fibrous filler, dyeing physical treatment, dyeing low molecular organic compound treatment, etc., can solve the problems of chopped carbon fiber breakage, ineffective antistatic performance, etc., to eliminate static electricity, improve antistatic properties, etc. Electrostatic properties, the effect of accelerating the speed of conduction

Inactive Publication Date: 2022-01-25

李丹丹

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Studies have shown that adding carbon materials to PVC products can greatly improve its antistatic properties. For example, by using the scraping method, 2mm chopped carbon fibers are mixed into PVC paste to make samples, and PVC products are obtained by plasticizing in an oven. The performance is greatly improved, and the surface resistance of PVC products can be reduced to 10 4 Ω order, but when the calendering method is used to prepare PVC products, a large number of chopped carbon fibers will be broken, and the addition of chopped carbon fibers has basically no effect on the antistatic performance of PVC products (Wang Guoquan, Zeng Jie. Carbon fiber / polyvinyl chloride blend antistatic Material Research [J]. Green Building, 1996,012 (004): 149-150.); Another example is patent CN 105507558 A which discloses a kind of antistatic PVC plastic floor, which adopts spraying on the surface of PVC floor to contain antistatic agent Modified poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid and graphene to improve the antistatic effect of PVC products, and reduce the surface resistance of PVC products to 10 5 Ω order of magnitude, its antistatic performance needs to be further improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

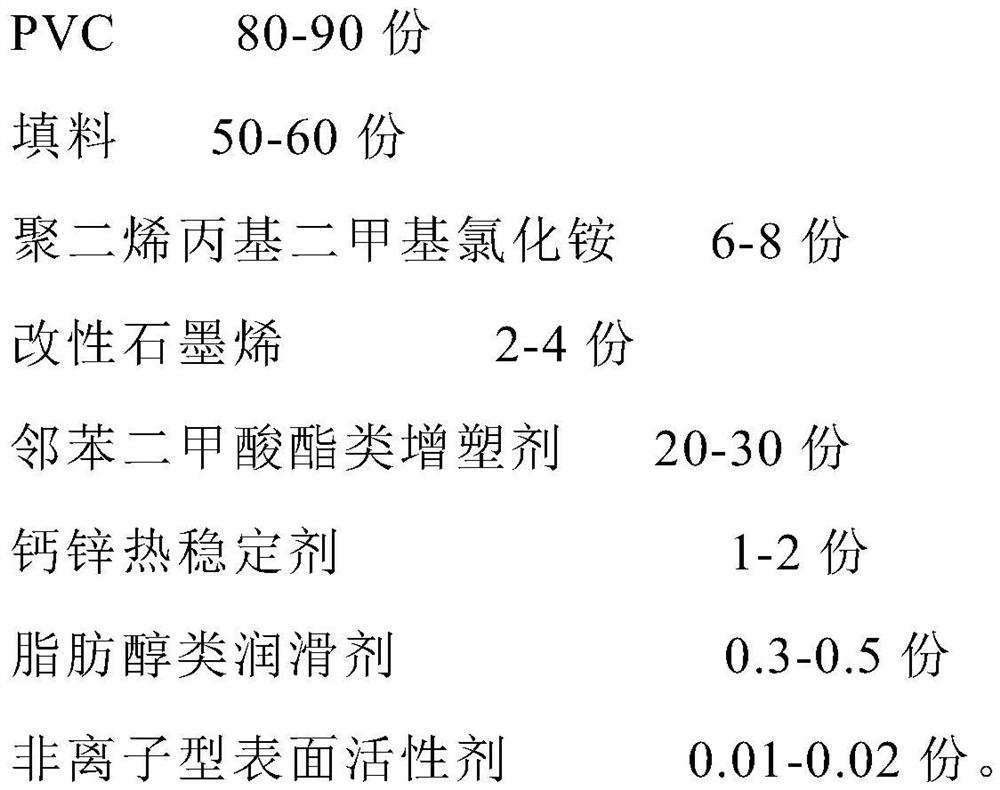

[0025] Anti-electrostatic PVC board includes the following ingredients with a weight of the part:

[0026]

Embodiment 2

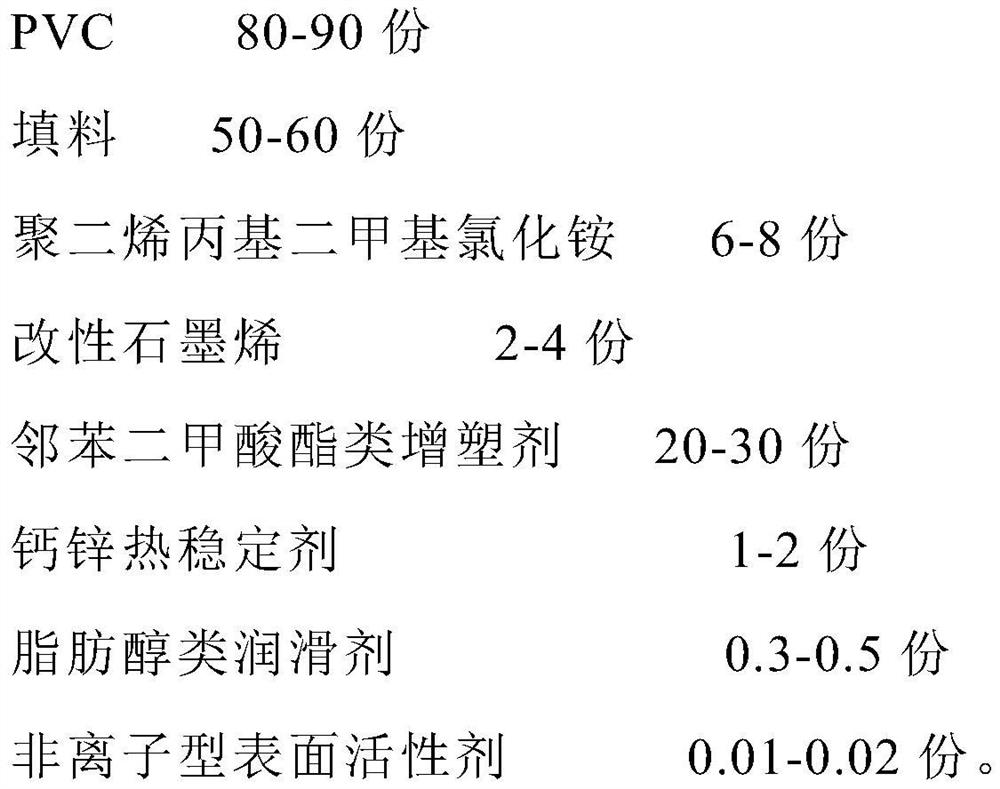

[0028] Anti-electrostatic PVC board includes the following ingredients with a weight of the part:

[0029]

Embodiment 3

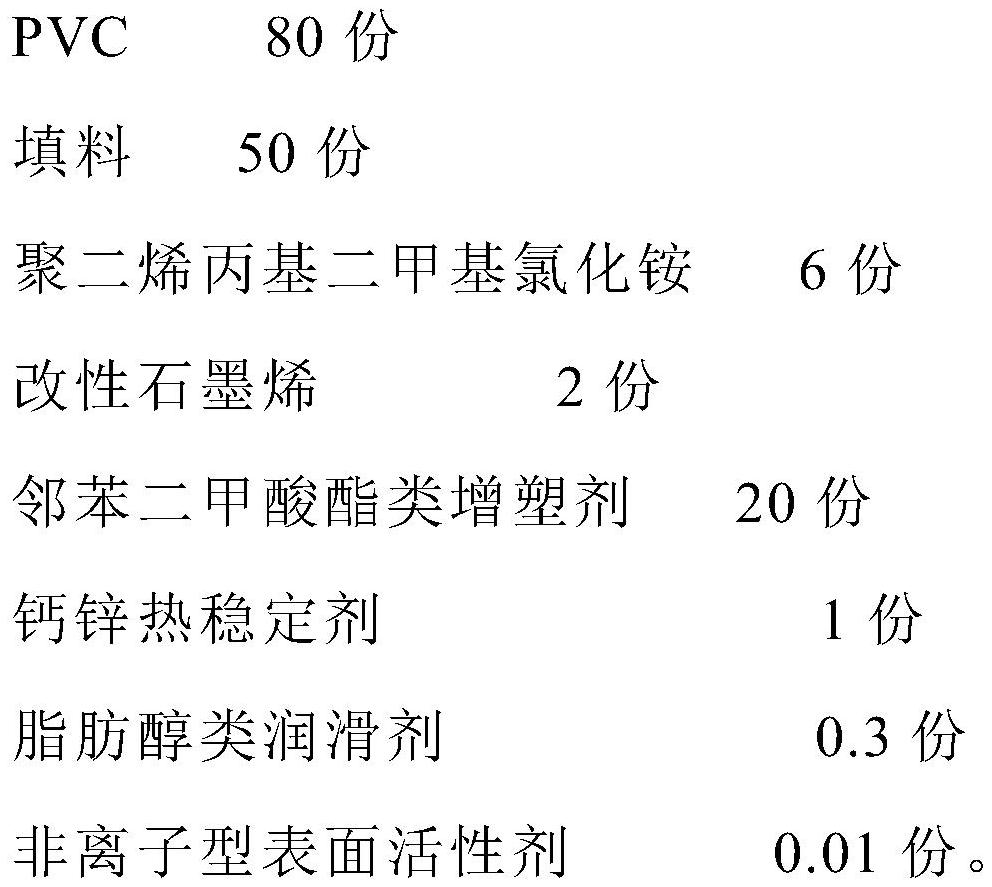

[0031] Anti-electrostatic PVC board includes the following ingredients with a weight of the part:

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of high polymer materials, in particular to an antistatic PVC board. The PVC plastic board is easy to generate electricity by friction, easy to collect dust and adsorb dirt, and generates an electrode phenomenon to people in the processing and using processes. In order to solve the problems, the invention provides the antistatic PVC board in which modified graphene is used as an auxiliary antistatic agent component, the modified graphene is sulfur-nitrogen co-doped graphene, and nitrogen is introduced into a carbon material, so that the electronegativity of the carbon material can be changed, carbon atoms around nitrogen atoms carry more positive charges, a PVC product is easy to generate negative charges when being rubbed, and the carbon atoms with positive charges around nitrogen atoms can neutralize a part of electrons; through introduction of the S element, graphene can generate more defect structures and active vacancies, the speed of conducting accumulated charges in a PVC system to the outside can be better accelerated, and static electricity is eliminated by neutralizing negative charges in the PVC product. The antistatic PVC board has a good application prospect.

Description

Technical field [0001] The present invention relates to the field of polymer materials, and more particularly to an antistatic PVC plate. Background technique [0002] Static electricity is a charging accumulation phenomenon in the surface of the insulating material, which is derived from friction, contact, or induction of electricity, for the insulator, which charges the plastic products to bring a series of charges due to charge. Hazard. In addition to enabling the production itself to easily vacuum, adsorb dirt, in the process of processing and use, it is seriously caused by severe accidents such as electrostatic discharge generating sparks. To solve the antistatic problem of plastic, the insulation resistance of the plastic parts can be reduced by adding antistatic agents. The charge is constantly generated during the friction of the object, and the simultaneous neutralization, the charge is mainly mainly through the volume of the friction itself, surface conduction, and thre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08L39/00C08K13/06C08K9/04C08K3/04C09C1/46C09C3/04C09C3/08

CPCC08L27/06C09C1/46C09C3/04C09C3/08C09C3/006C08L2201/04C08K2201/017C08L39/00C08K13/06C08K9/04C08K3/042

Inventor 李丹丹

Owner 李丹丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com