Antibacterial, flame-retardant toughening multifunctional ionomer aid, preparation method and application thereof

An ionomer and multi-functional technology, applied in the field of polymer compound preparation, can solve the problems of polylactic acid flame retardancy, toughening and antibacterial simultaneous modification, etc., and achieve the reduction of industrial processing costs, low investment and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

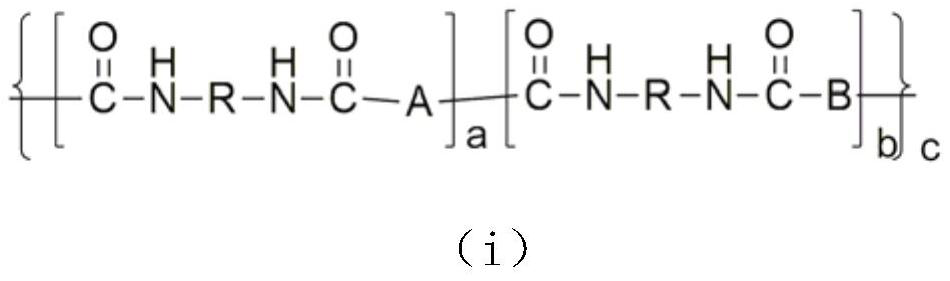

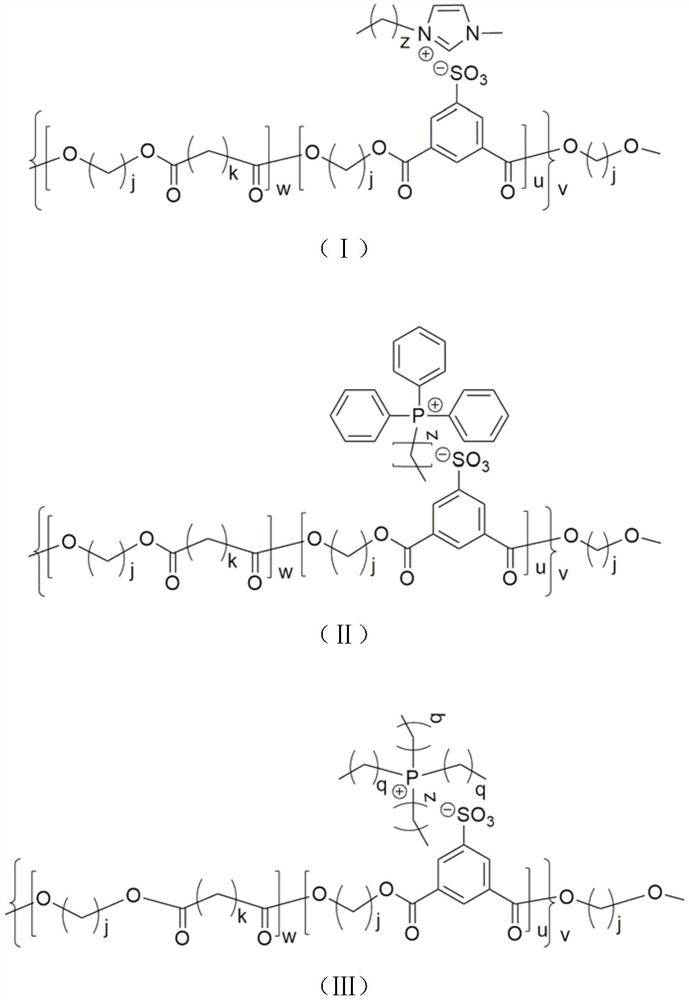

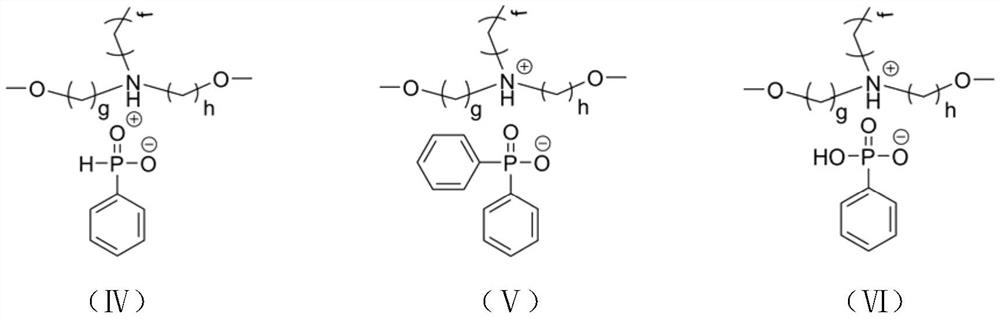

Method used

Image

Examples

Embodiment 1

[0058] This embodiment is used to illustrate the preparation method of flame retardant, toughening and antibacterial multifunctional ionomer additives in the present invention:

[0059] Synthesis of S1 antibacterial ionic salt:

[0060] S1-1: 1.05mol iodomethane and 1mol triphenylphosphine in N 2 Under protection, react at 40°C for 0.5h, pour the product into a beaker filled with ethyl acetate and stir for at least 1h, in which the mass of the precipitant is more than 2 times the mass of the product (subject to the submerged product), then suck and dry. The methyltriphenylphosphine salt is obtained.

[0061] S1-2: Dissolve the obtained methyl triphenylphosphine salt in chloroform, the mass of the solvent chloroform is more than five times that of the methyl triphenylphosphine salt, and add to methyl isophthalate benzenesulfonate after the dissolution is complete The sodium acid concentration is 5wt% aqueous solution to carry out the extraction reaction, and the molar feed ra...

Embodiment 2

[0064] Embodiments 2-6 are basically the same as Embodiment 1, the difference lies in the selection of parameters and materials, see the content in Table 1 for details. For Example 6, its chain extension reaction adopts scheme B, that is: the prepolymer, the tertiary amine with dihydroxy groups and diisocyanate are mixed, and the chain extension reaction is carried out in the extruder under the protection of an inert gas, and then Extrusion to obtain chain-extended products. The difference between Example 5 and Example 6 lies in that the former uses the chain extension reaction of Scheme A, and the latter adopts the chain extension reaction of Scheme B. More specifically, the chain extension reaction in Example 6 is: pre-mix the prepolymer and N-methyldiethanolamine with bishydroxyl groups according to the ratio of 8:2 in the mixer and add 1,6- Hexamethylene diisocyanate, the amount of 1,6-hexamethylene diisocyanate accounts for 1 times the total number of hydroxyl moles of p...

Embodiment 7

[0069] This embodiment is used to illustrate the application of multifunctional ionomer auxiliary agent in polylactic acid modification in the present invention:

[0070]Carry out melt blending or solvent blending with the ionomer auxiliary agent obtained in Example 1 and polylactic acid (PLA), select melt blending in the present embodiment, the addition amount of ionomer auxiliary agent can be polylactic acid mass 0.1-1 times of that, in this embodiment, specifically, the amount of ionomer additive added per 100g of PLA is 30g, the temperature of melt blending is 180°C (optional temperature range 175-220°C), the melt blending The time is 5 minutes (2-8 minutes can be selected). The melt-blended product is extruded and granulated to obtain modified polylactic acid. Then, after the granule product is melted, it is made into a film with a thickness of 0.5mm by hot pressing on a flat vulcanizer. The tensile strength and elongation at break are measured and calculated by a tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com