High-performance wood-plastic composite material and preparation method thereof

A wood-plastic composite material, high-performance technology, applied in the field of wood-plastic composite material and its preparation, can solve the problems of weak interfacial interaction force, low mechanical strength, easy aging, etc., and achieve the effect of high internal fiber density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

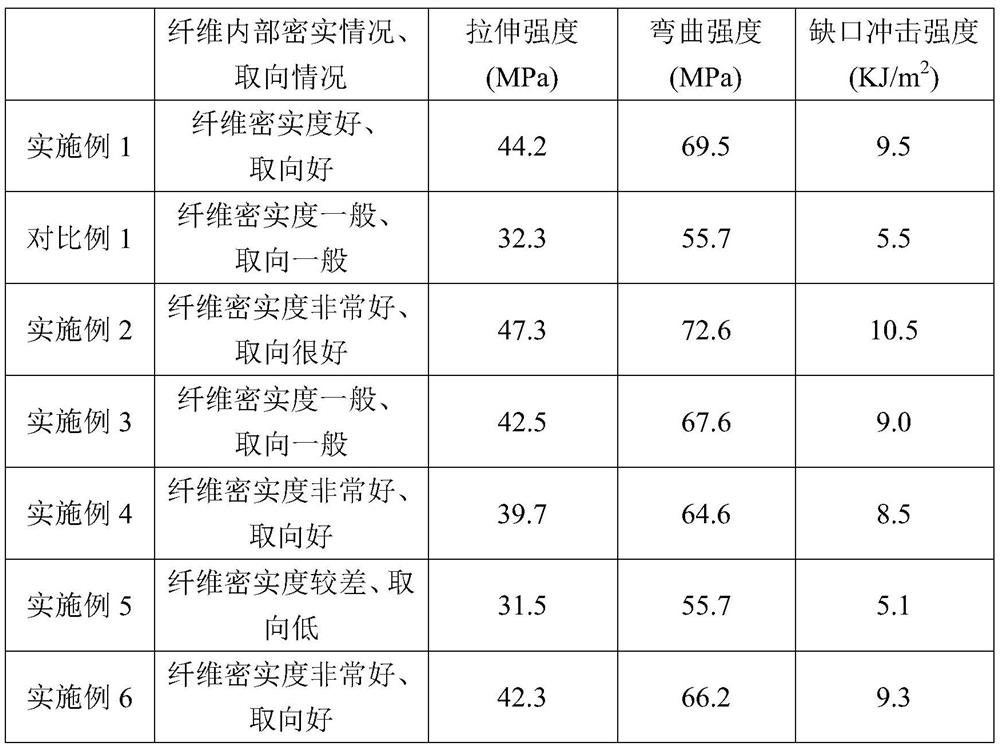

Examples

Embodiment 1

[0023] A high-performance wood-plastic composite material, comprising the following raw materials, the parts by weight of each component are as follows: 100 parts of thermoplastic polypropylene, based on the weight of thermoplastics, 80 parts of modified sisal fiber, 8 parts of PP-GMA, stearic acid 8 parts, 1 part of antioxidant 1010, 2 parts of antioxidant 168, 30 parts of aluminum hydroxide, 3 parts of SHT-115.

[0024] The preparation method comprises the following steps:

[0025] Plant fiber modification treatment: After the sisal fiber is preliminarily combed by a carding machine to remove surface impurities, 1000g of sisal fiber is put into 3000g of NaOH and NaOH 2 SO 3 The mixed boiling aqueous solution was continuously treated for 3 hours, wherein the concentration of NaOH was 2.5mol / L, Na 2 SO 3 The concentration is 0.4mol / L. Then use clean water to wash the treated sisal long fibers repeatedly for many times, and then press the treated sisal fibers through a mold...

Embodiment 2

[0035] A high-performance wood-plastic composite material, comprising the following raw materials, the parts by weight of each component are as follows: 100 parts of thermoplastic polypropylene, based on the weight of thermoplastics, 80 parts of modified sisal fiber, 8 parts of PP-GMA, stearic acid 8 parts, 1 part of antioxidant 1010, 2 parts of antioxidant 168, 30 parts of aluminum hydroxide, 3 parts of SHT-115.

[0036] The preparation method comprises the following steps:

[0037] Plant fiber modification treatment: After the sisal fiber is preliminarily combed by a carding machine to remove surface impurities, 1000g of sisal fiber is put into 3000g of NaOH and NaOH 2 SO 3 The mixed boiling aqueous solution was continuously treated for 3 hours, wherein the concentration of NaOH was 2.5mol / L, Na 2 SO 3 The concentration is 0.6mol / L. Then use clean water to wash the treated sisal long fibers repeatedly for many times, and then press the treated sisal fibers through a mold...

Embodiment 3

[0041] A high-performance wood-plastic composite material, comprising the following raw materials, the parts by weight of each component are as follows: 100 parts of thermoplastic polypropylene, based on the weight of thermoplastics, 80 parts of modified flax fiber, 8 parts of PP-GMA, and 8 parts of stearic acid 1 part, 1 part of antioxidant 1010, 2 parts of antioxidant 168, 30 parts of aluminum hydroxide, 3 parts of SHT-115.

[0042] The preparation method comprises the following steps:

[0043] Plant fiber modification treatment: After the flax fiber is preliminarily combed by a carding machine to remove surface impurities, 1000g of flax fiber is put into 3000g of NaOH and NaOH 2 SO 3 The mixed boiling aqueous solution was continuously treated for 3 hours, wherein the concentration of NaOH was 2.5mol / L, Na 2 SO 3 The concentration is 0.4mol / L. Then use clear water to wash the treated flax long fibers repeatedly for several times, and then press the treated flax fiber thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com