Semiconductor device mixed with graphene electrode and manufacturing method of device

A technology of graphene electrodes and manufacturing methods, which is applied in the manufacture of semiconductor devices, electrical components, final products, etc., can solve the problems of weak signal detection ability, low metal light transmittance, small wavelength range, etc., and achieve strong detection of weak signals ability, high photoelectric conversion efficiency, and the effects of low reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

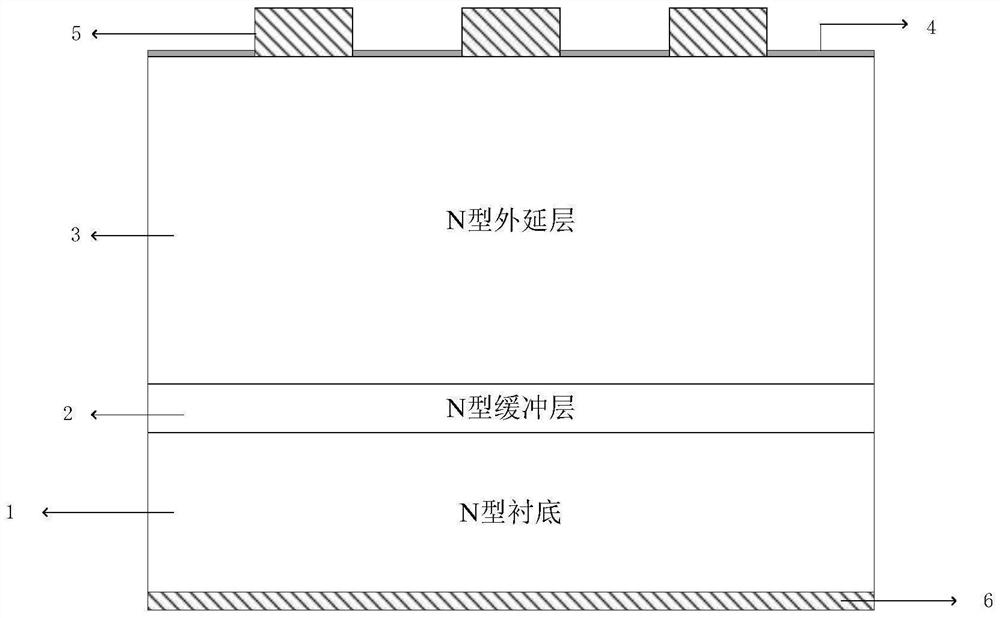

[0031] A kind of semiconductor device of mixed graphene electrode of the present invention comprises: N-type substrate 1, is provided with back electrode metal 6 on one surface of N-type substrate 1, is provided with on the other surface of N-type substrate 1 The N-type buffer layer 2 is provided with an N-type epitaxial layer 3 on the N-type buffer layer 2, and the surface of the N-type epitaxial layer 3 is provided with a graphene electrode 4 and a high work function metal forming a Schottky contact with the N-type epitaxial layer 3 Electrode 5.

[0032] The upper surface of the N-type epitaxial layer 3 is a plurality of protrusions, the graphene electrode 4 is located on the top of the protrusions, and the high work function metal electrode 5 is located on the side of the protrusions and the upper surface of the N-type epitaxial layer 3 .

[0033] The high work function metal electrode 5 is embedded in the upper surface of the N-type epitaxial layer 3, and the graphene elec...

Embodiment 2

[0042] The structure of the present invention is the same as embodiment 1, and the manufacture method of described structure:

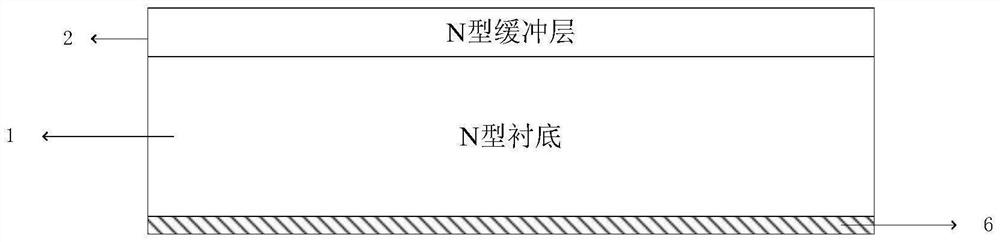

[0043] Step 1 as figure 2 As shown, take an N-type substrate 1, use a sputtering process, make a back electrode metal 6 on one surface of the N-type substrate 1, and grow an N-type buffer layer 2 on the other surface of the N-type substrate,

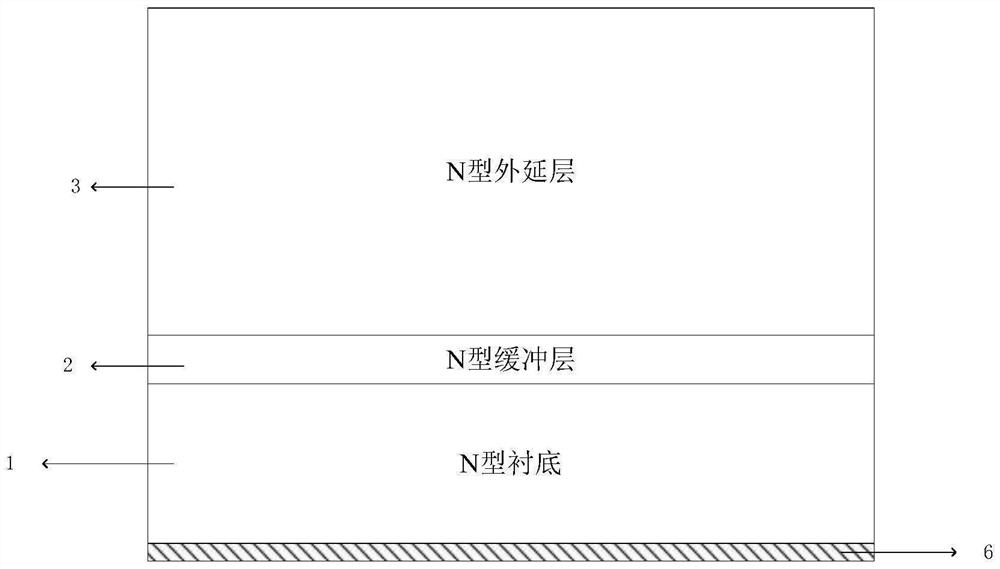

[0044] Step 2 as image 3 As shown, an N-type epitaxial layer 3 is formed on the surface of the N-type buffer layer 2,

[0045] Step 3 as Figure 4 As shown, the graphene is transferred to the surface of the N-type epitaxial layer 3 by using the transfer method, and then, using the plasma reactive etching technique, part of the graphene is etched away, leaving the graphene 4 distributed at intervals,

[0046] In step 4, a sputtering process and a metal lift-off process are used to form high work function metals 5 arranged at intervals in close contact with the graphene 4 on the N-type epitaxial layer 3 to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com