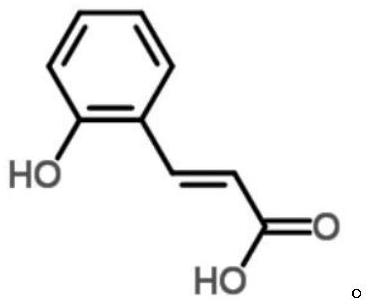

Application of o-hydroxycinnamic acid of in removal of harmful benthic diatom

A technology of o-hydroxycinnamic acid and benthic diatoms, applied in the fields of application, herbicides and algicides, seaweed cultivation, etc., can solve problems such as diatoms cannot be fundamentally removed, environmental damage is great, and secondary pollution , to achieve the effect of saving manpower, low price and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The acquisition of embodiment 1 o-hydroxycinnamic acid

[0027] O-hydroxycinnamic acid is extracted from Gracilaria isobranchus. Gracilaria heterochia was collected from Fengjiawan, Wenchang City, Hainan Province (19°24′49″N, 110°42′53″E). Take 20mg of dry powder sample of Gracilaria isobrachiae into a 1.5mL centrifuge tube, add 400μL of extract solution (acetonitrile:methanol=1:1, volume ratio), vortex and mix for 30s, then extract with low-temperature ultrasound for 30min (5°C, 40KHz), Place the sample at -20°C for 30 minutes, centrifuge at 13,000g at 4°C for 15 minutes, remove the supernatant, dry it with nitrogen, add 120 μL of complex solution (acetonitrile: water = 1:1, volume ratio) to redissolve, and extract with low-temperature ultrasonic 5min (5°C, 40KHz), centrifuge at 4°C, 13000g for 5min, pipette the supernatant into a vial with an inner insert for mass spectrometry analysis, sample preparation design 6 parallel. Take an equal volume of all sample metabol...

Embodiment 2

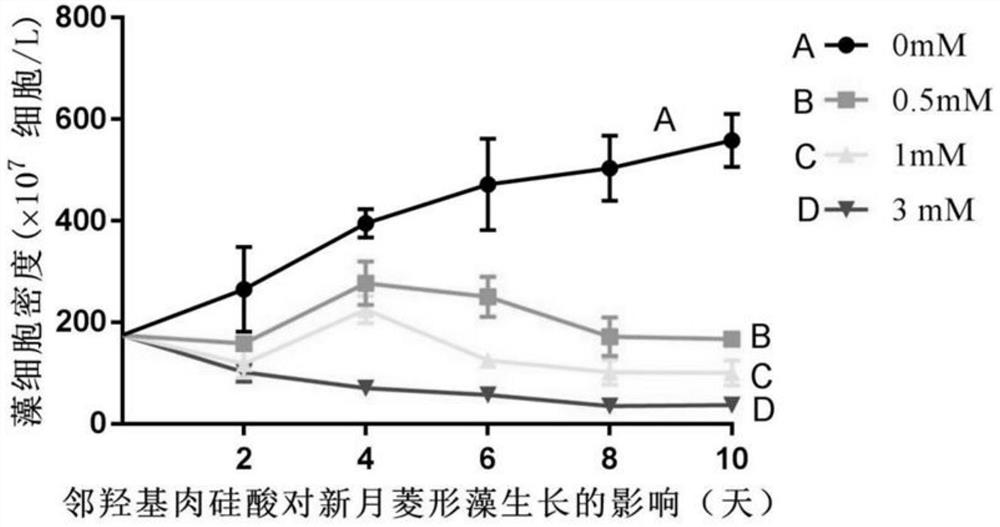

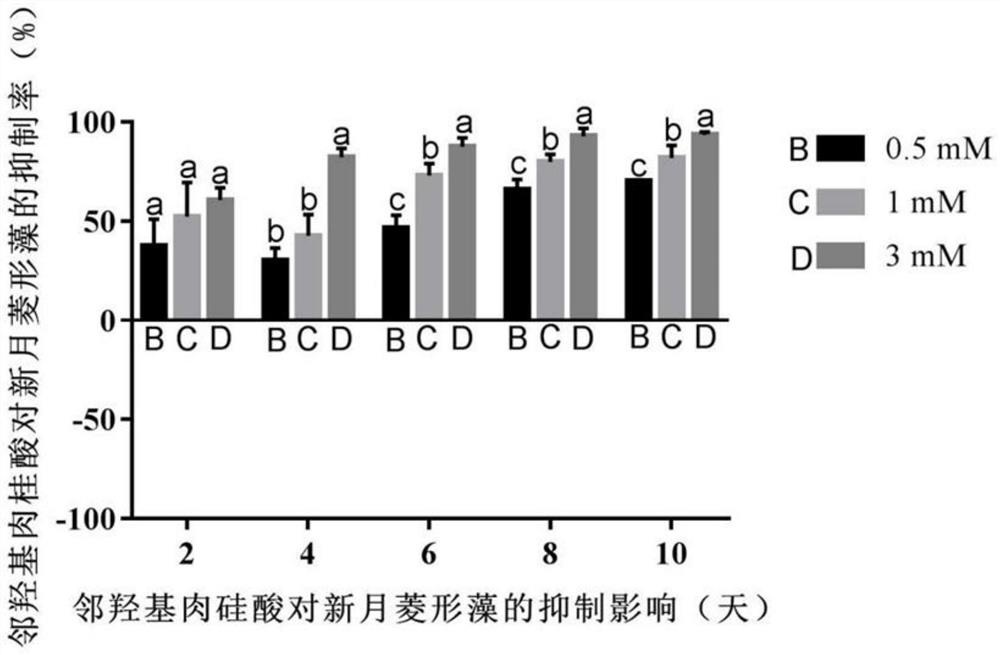

[0028] Embodiment 2 A kind of method of removing adsorption type benthic diatoms (taking Nitzschia crescentus as model)

[0029] (1) Choose a PE plastic square water tank without a cover with a water capacity of 600L. After the tank wall is scrubbed, the tank wall is repeatedly splashed with a potassium permanganate solution with a concentration of 5 mg / L, soaked for 10 minutes, and then disinfected with seawater. Rinse well.

[0030] (2) Inject fresh sand-filtered seawater into the cleaned water tank, cover the water inlet with a 500-mesh filter bag to prevent the entry of harmful organisms, and fill the water to 500L. Disinfect the seawater with 50mL 30% available chlorine bleach solution and let it stand for 6 hours. Before seawater is used, add 9.24g of sodium thiosulfate for neutralization and fully aerate for 3 hours.

[0031] (3) Add o-hydroxycinnamic acid dissolved in 0.1% dimethyl sulfoxide to the water tank with sterilized seawater, so that the final concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com