Method for constructing g-C3N4 quantum dot/carbon composite material based on non-covalent bond effect and application thereof

A carbon composite material and non-covalent bond technology, applied in nanotechnology, carbon compounds, chemical instruments and methods for materials and surface science, can solve unsatisfactory catalytic activity, low electron mobility, and small specific surface area and other issues to achieve the effect of low cost, low energy and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

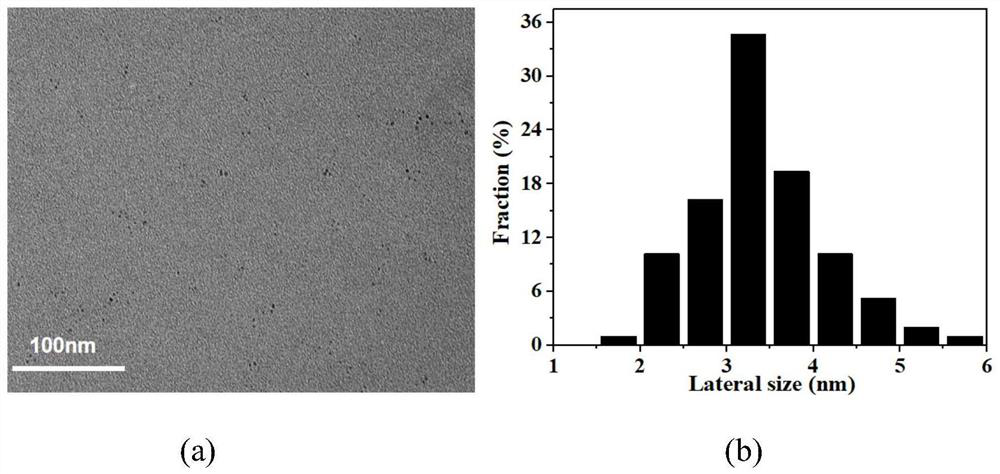

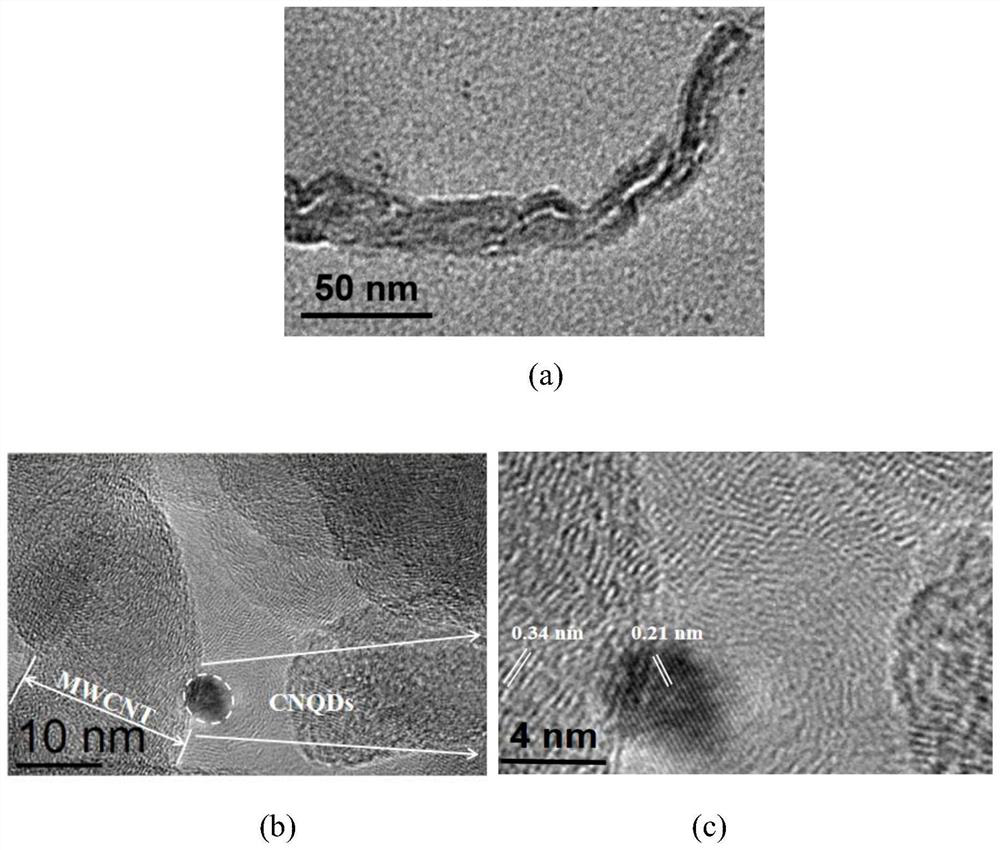

[0025] Step 1, 10 g of melamine is preferably calcined at a high temperature of 550 ° C for 4 h, and the grinding is obtained by G-C. 3 N 4 Powder. Step 2, refer to G-C in step 1 3 N 4 Powder 1200 mg is placed in a centrifuge tube, slowly add liquid nitrogen, and place the centrifugal tube into a Duwar bottle containing liquid nitrogen, plus the foam cover, low temperature pretreatment 60 min. Step 3, remove the G-C after pre-processing in step 2 3 N 4 The powder was added to a solution containing 200 ml of water and 200 ml of isopropanol, and the liquid phase stripped 4 h. Step 4, the mixture of step 3 is removed from the centrifuge of 12000 rpm to a centrifuge of 12000 rpm, and the centrifugal upper layer is collected, and the dialysis pocket of the centrifuge is 200, and the dialysis bag of 200 is 3 days to remove the solvent, and the dialysis liquid is frozen. Get GC 3 N 4 Quantum dots. Step 5, weigh the G-C in step 4 3 N 4 Quantum dots 2 mg and carboxylated multi-walled carbo...

Embodiment 2

[0027] Step 1, 10 g of melamine is preferably calcined at a high temperature of 550 ° C for 4 h, and the grinding is obtained by G-C. 3 N 4 Powder. Step 2, refer to G-C in step 1 3 N 4 Powder 1200 mg is placed in a centrifuge tube, slowly add liquid nitrogen, and place the centrifugal tube into a Duwar bottle containing liquid nitrogen, plus the foam cover, low temperature pretreatment 60 min. Step 3, remove the G-C after pre-processing in step 2 3 N 4 The powder was added to a solution containing 200 ml of water and 200 ml of isopropanol, and the liquid phase stripped 4 h. Step 4, the mixture of step 3 is removed from the centrifuge of 12000 rpm to a centrifuge of 12000 rpm, and the centrifugal upper layer is collected, and the dialysis pocket of the centrifuge is 200, and the dialysis bag of 200 is 3 days to remove the solvent, and the dialysis liquid is frozen. Get GC 3 N 4 Quantum dots. Step 5, weigh the G-C in step 4 3 N 4 Quantum dots 2 mg and carboxylated multi-walled carbo...

Embodiment 3

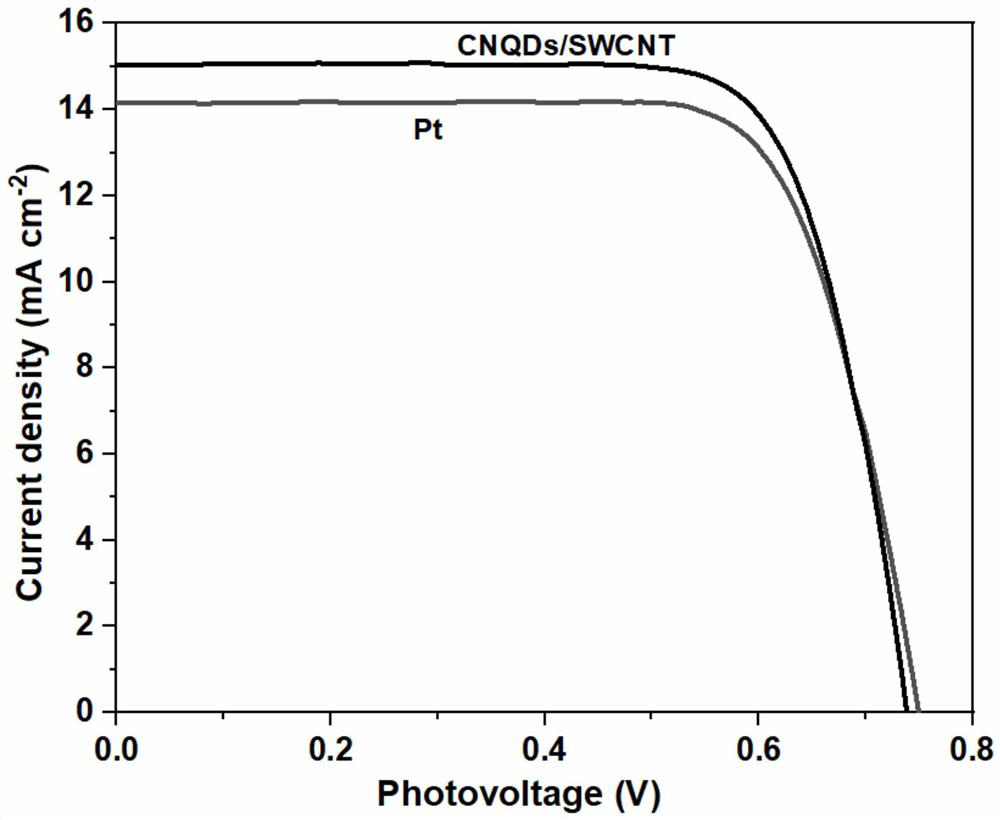

[0029] Step 1, 6G urea is calcined at a nitrogen atmosphere of 500 ° C for 3 h, and the grinding is obtained to obtain G-C. 3 N 4 Powder. Step 2, refer to G-C in step 1 3 N 4 Powder 1600 mg is placed in a centrifuge tube, slowly add liquid nitrogen to the tube into a Duwar bottle containing liquid nitrogen, plus the foam cover, low temperature pretreatment for 30 min. Step 3, remove the G-C after pre-processing in step 2 3 N 4 The powder was added to a solution of 800 ml of acetone, and the liquid phase stripped 3 h. Step 4, the mixture of step 3 is removed from the centrifuge of the rotational speed of 11000 rpm, and the centrifugal upper layer is collected, and the dialysis bag of the centrifugation is collected by dialysis bags of 2002 to remove the solvent, and the dialysis liquid is frozen. Get GC 3 N 4 Quantum dots. Step 5, weigh the G-C in step 4 3 N 4 Quantum dots 3 mg and carboxylated single-walled carbon nanotubes were added to 100 mg of distilled water, and the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com